Lithium battery production technology

A production process, lithium battery technology, applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, final product manufacturing, etc., can solve the problems of easy agglomeration of powder materials, inaccurate weighing, large vibration, etc., to achieve a high degree of automation, Effect of reducing labor force and alleviating vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific embodiments.

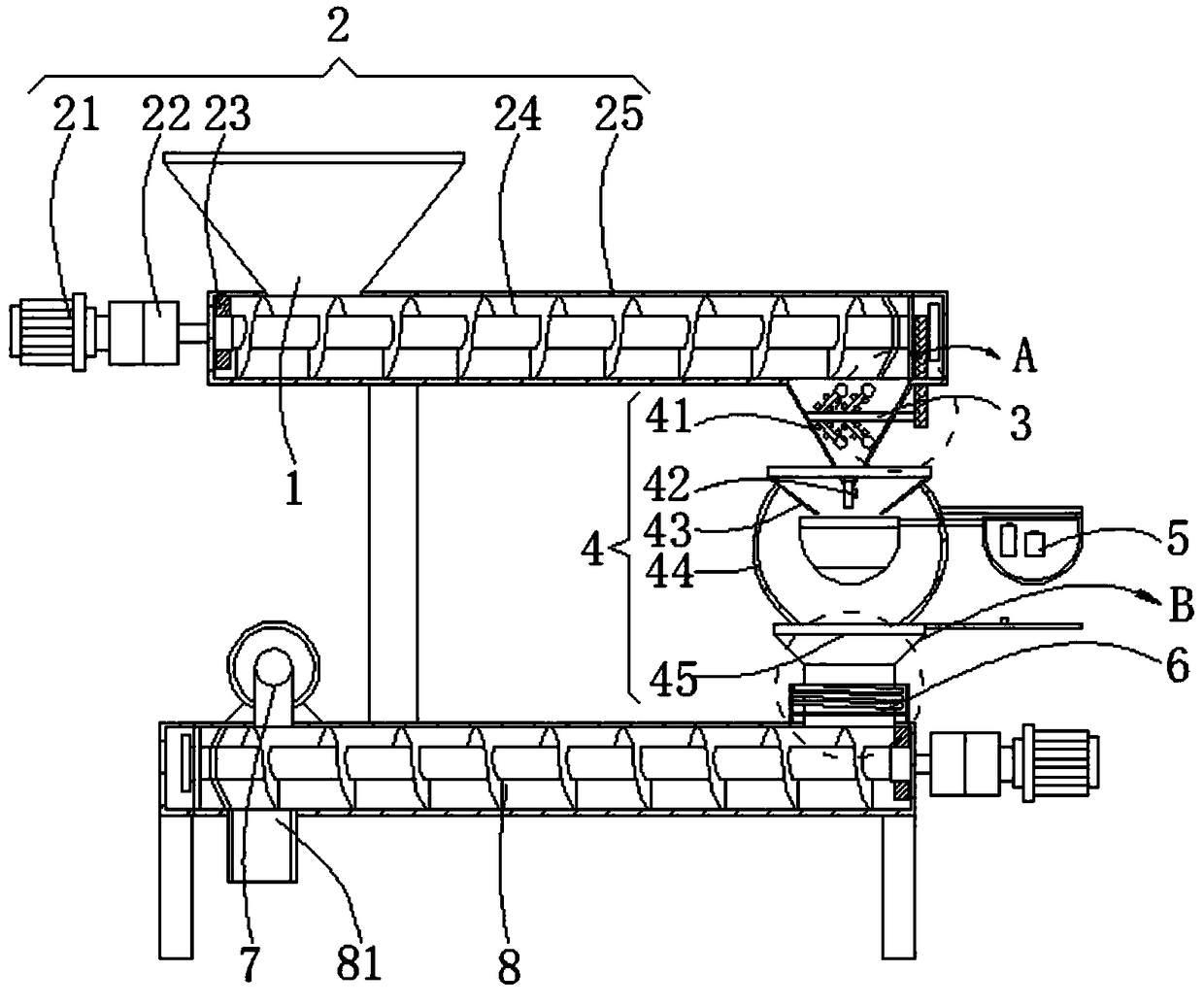

[0032] like figure 1 As shown, a lithium battery production process according to the present invention, the process comprises the following steps:

[0033] s1: Put the electrode active material, binder, etc. into the spiral reamer scale for weighing;

[0034] s2: Mix the electrode active material, binder, etc. weighed in s1 into a solvent and put it into a vacuum mixer to stir evenly to form a slurry;

[0035] s3: coating the slurry in s2 on the metal foil, and baking, rolling and slitting to make a lithium battery plate;

[0036] s4: transport the lithium battery plate in s3 to the next process;

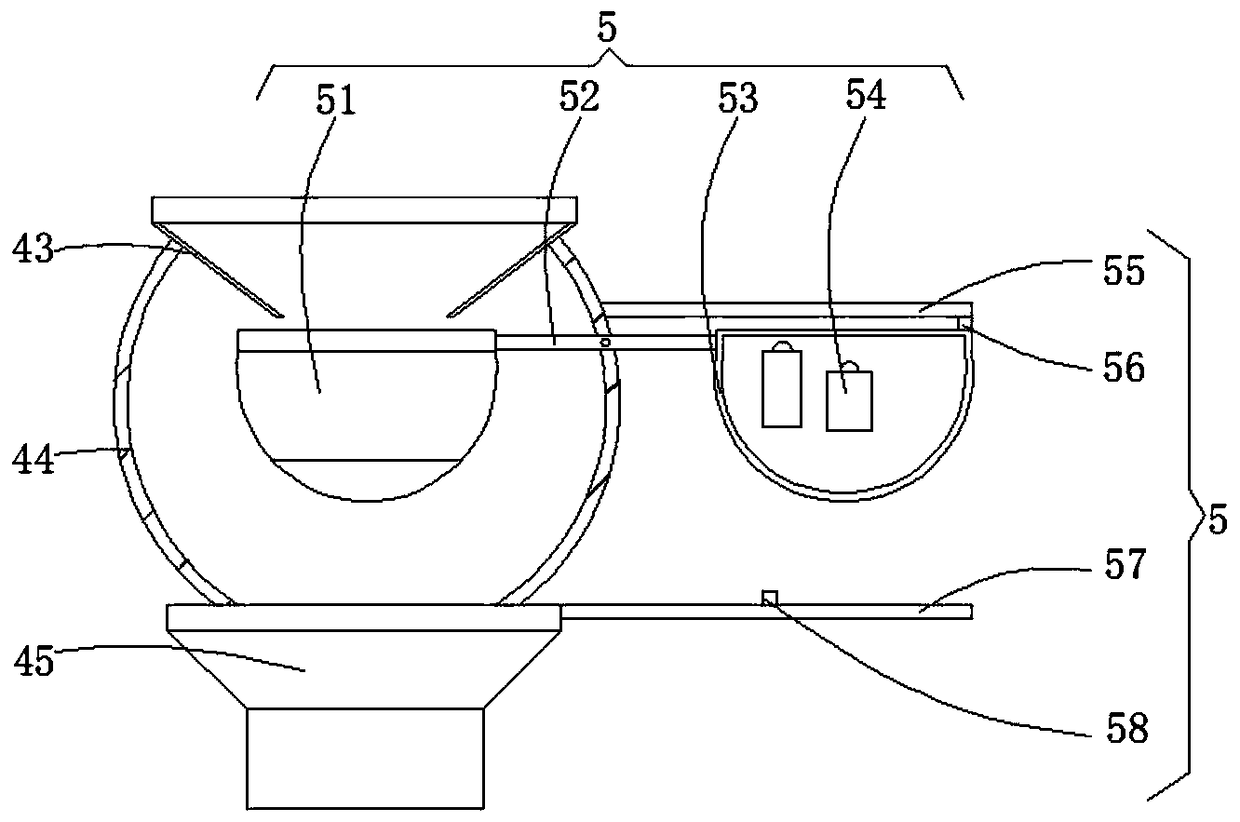

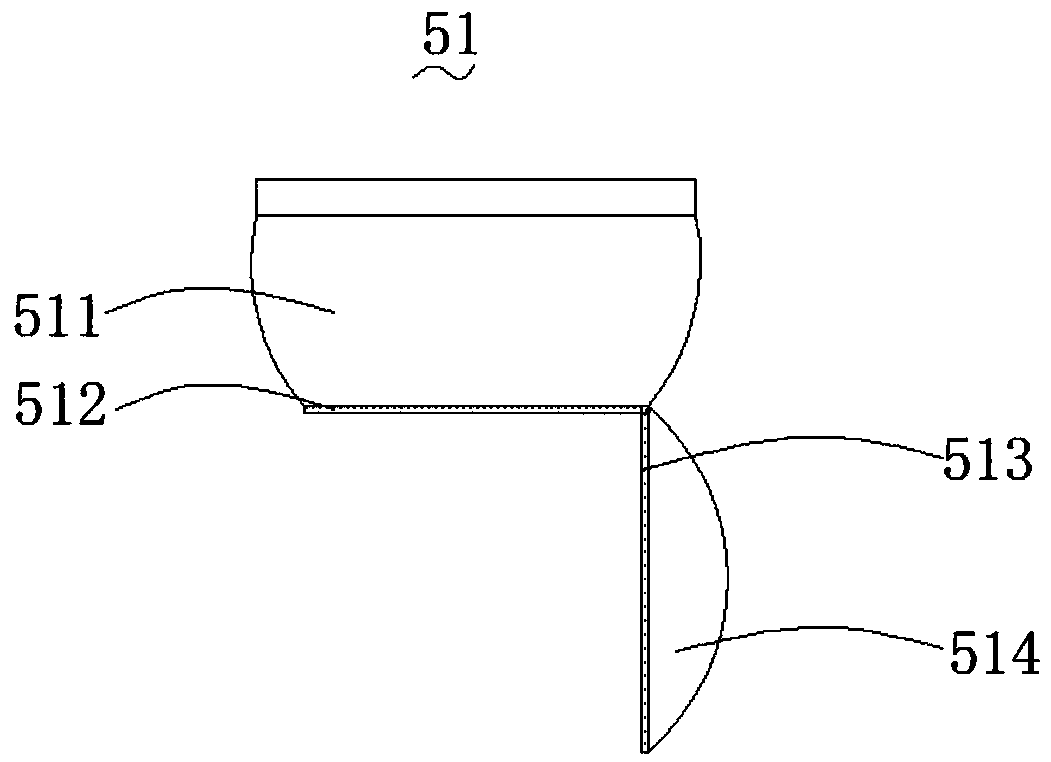

[0037]Among them, the spiral reamer scale includes a storage hopper 1, a first conveying mechanism 2, a crushing mechanism 3, a blanking mechan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap