A flaw detection and processing system for a steel plate coiler

A processing system and coiling machine technology, applied in the direction of material magnetic variables, etc., can solve the problems of high labor intensity, low degree of automation, waste and other problems of workers, and achieve high defect detection processing efficiency, high degree of automation, and good detection quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below in conjunction with accompanying drawing:

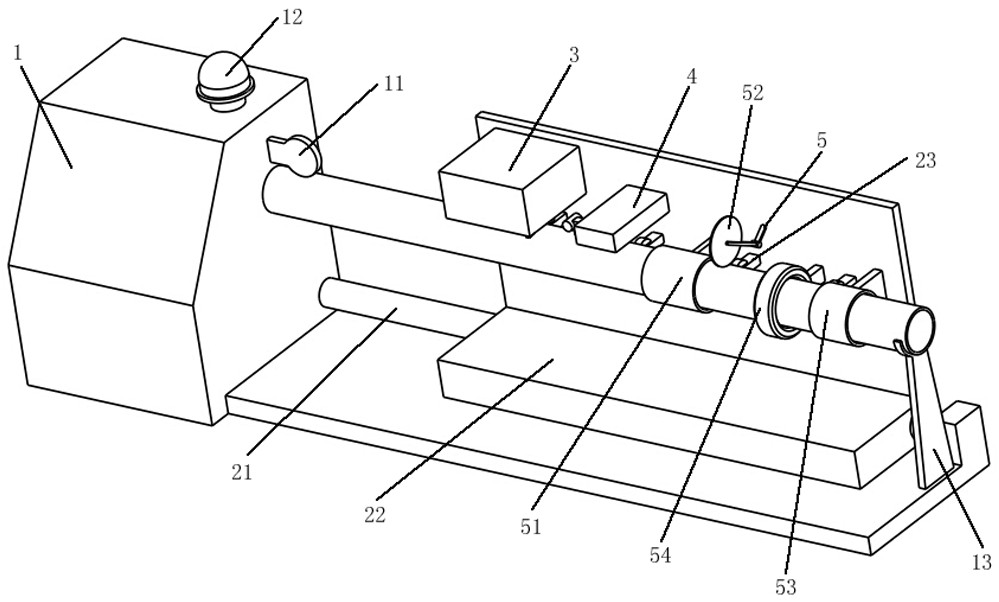

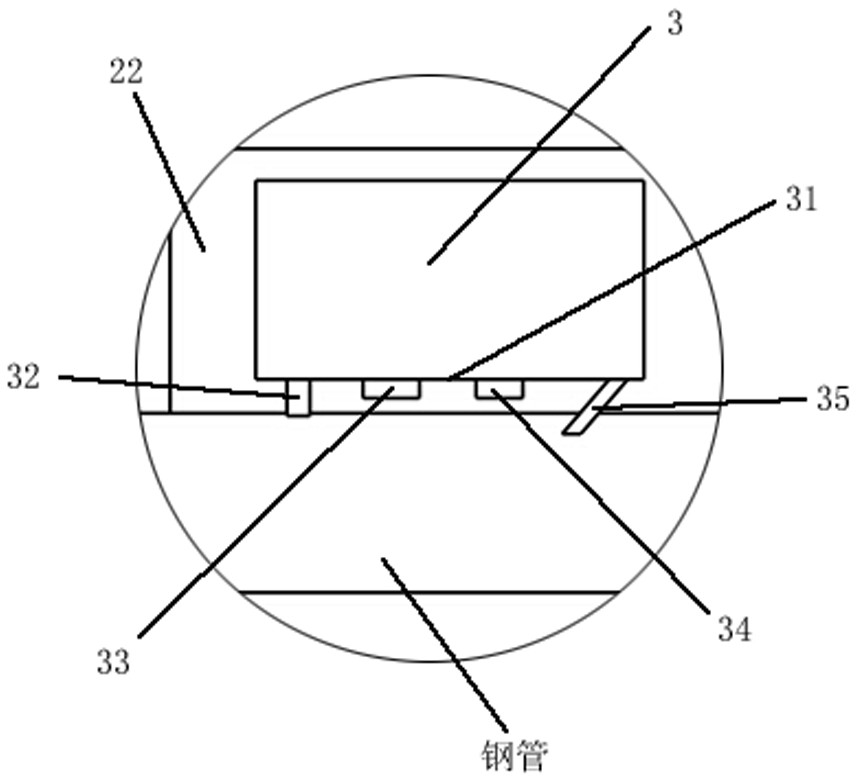

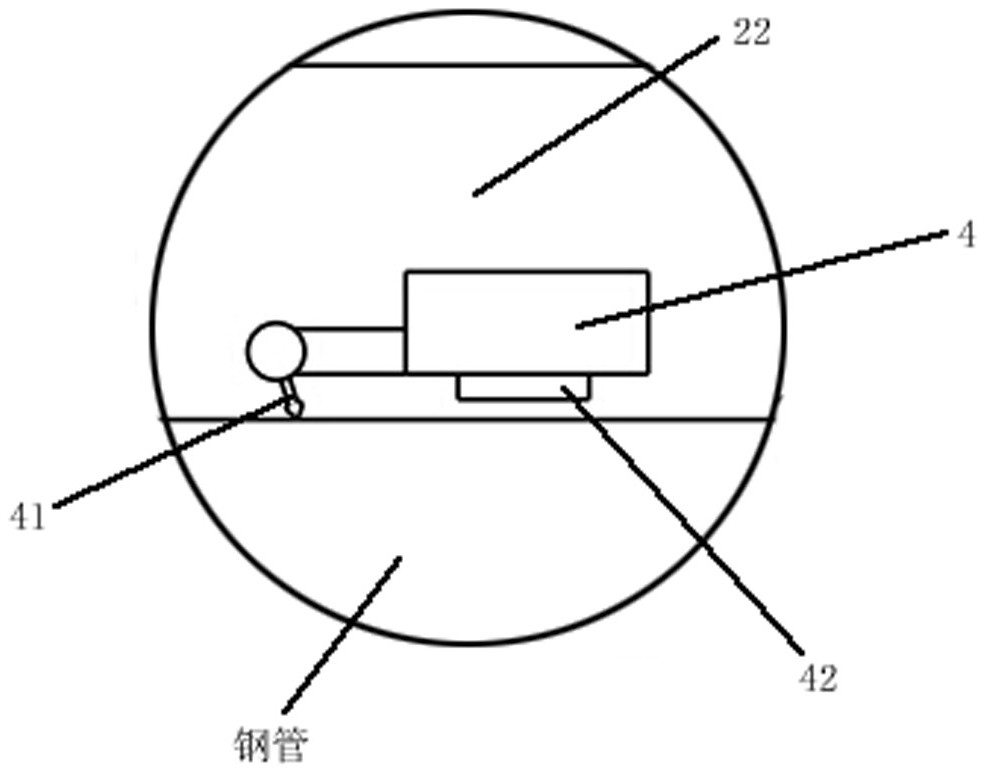

[0033] Such as figure 1 The flaw detection processing system of a steel pipe reel shown in the figure includes a pipe reel body 1 that moves the reel in one direction and welds it into a seamless steel pipe. There is a flaw detection processing device extending from the pipe exit direction of the main body 1. The flaw detection processing device includes a guide rail 21 perpendicular to the pipe exit direction of the coiler and a mover that can be moved on the guide rail 21 through a walking device. A magnetic flaw detection device 3 , a surface quality inspection device 4 and a cutting device 5 are arranged at intervals along the pipe outlet direction on the bracket 22 ; The hose reel body 1 also includes an auxiliary bracket 13 located outside of the flaw detection processing device in the pipe outlet direction. The steel pipe sent out from the pipe reel body 1 along the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com