Distinguishable photochromic privacy glass for vehicle

A technology for dimming glass and vehicles, used in optics, nonlinear optics, instruments, etc., can solve the problems of affecting sealing performance, difficult to achieve automatic operation, low production efficiency, etc., to improve production efficiency, improve product aesthetics and Tightness, the effect of realizing automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

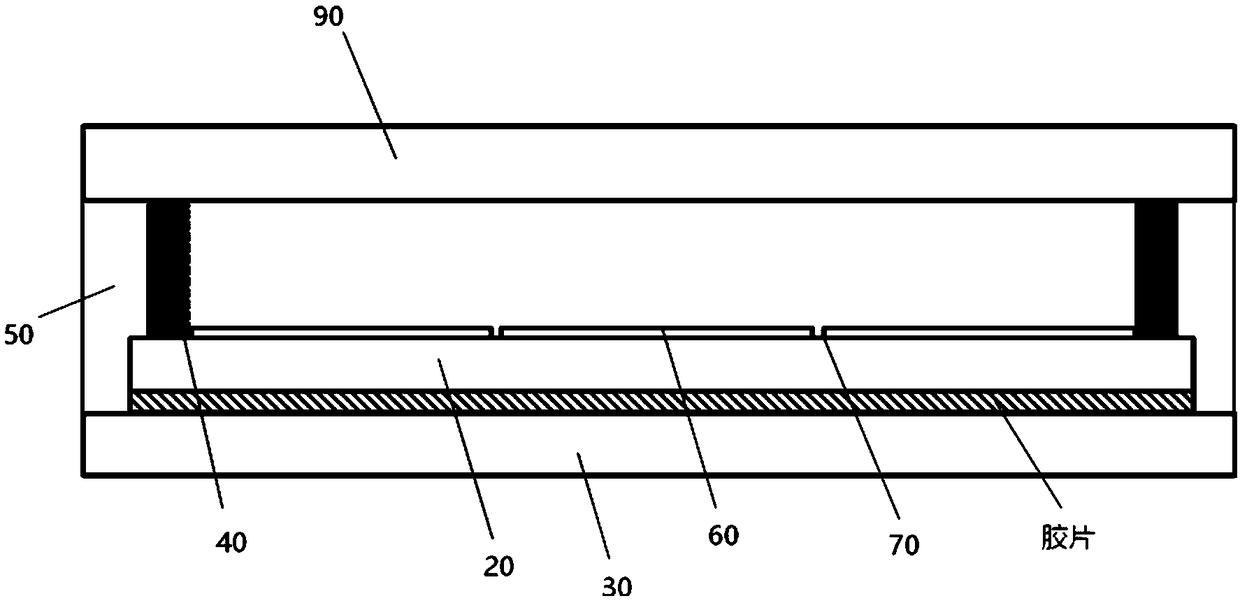

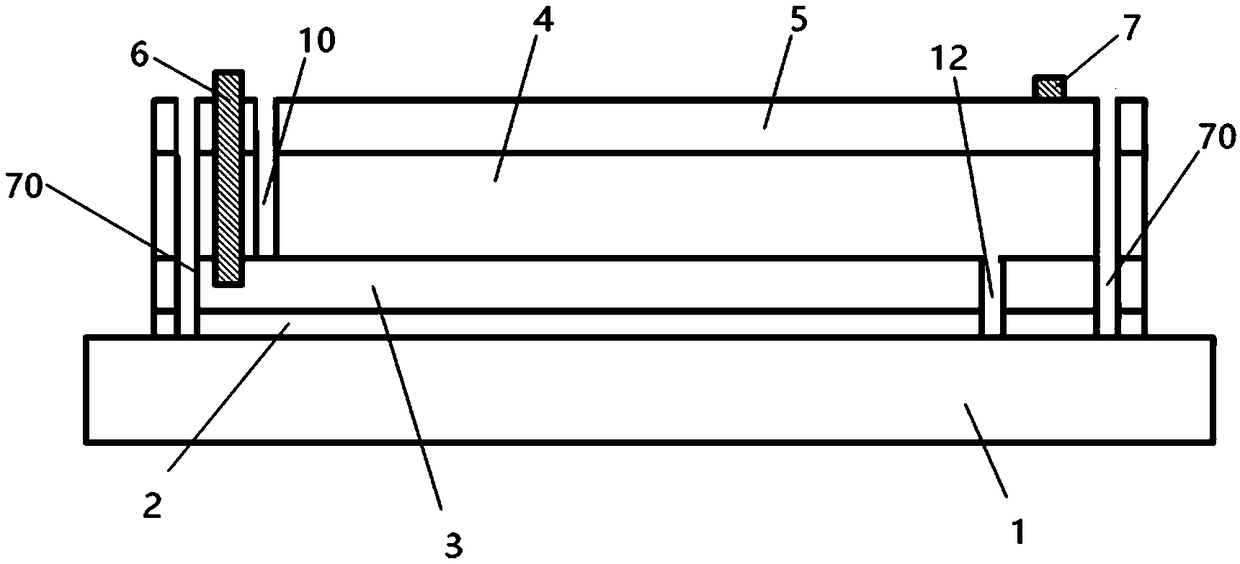

[0018] Such as figure 1 As shown, the partitionable light-changing glass for vehicles includes a hollow glass substrate 90, a color-changing glass substrate 20, and a laminated glass substrate 30 arranged in parallel in sequence. The hollow glass substrate and the color-changing glass substrate A hollow cavity is formed between them by an annular spacer bar 40 , and the periphery of the annular spacer bar is sealed by an edge sealing body 50 .

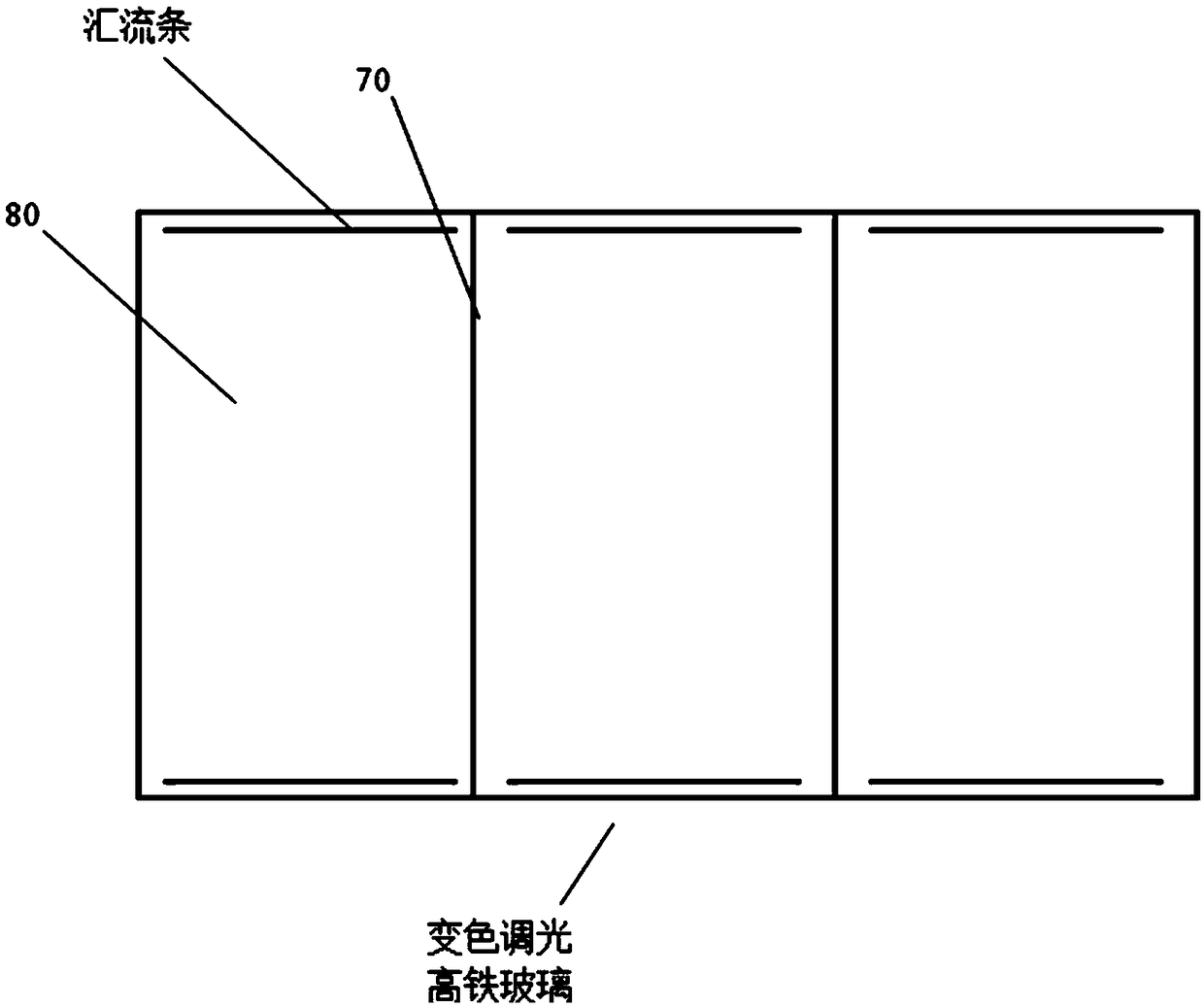

[0019] The surface of the color-changing glass substrate 20 located in the hollow cavity is provided with an electrochromic coating 60, and the electrochromic coating is provided with at least one full laser groove 70 for insulation and partition in the horizontal or vertical direction, and the full laser groove can The electrochromic coating is divided into at least two discoloration control regions ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com