Soft measurement method for temperature of rotary kiln burning zone

A firing belt and rotary kiln technology, applied in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

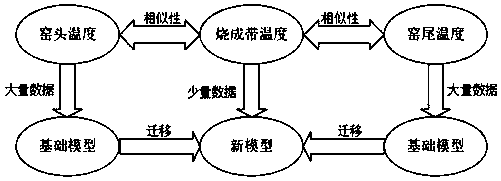

Method used

Image

Examples

Embodiment 1

[0080] Figure 5 , Image 6 In order to use the robust multi-variable anomaly processing to eliminate the abnormal points of kiln tail temperature and kiln head temperature, the parameter selection is 0.95. if Then it is considered as an outlier and removed; if considered normal. The preprocessed normal data are used for kiln tail temperature and kiln head temperature modeling.

Embodiment 2

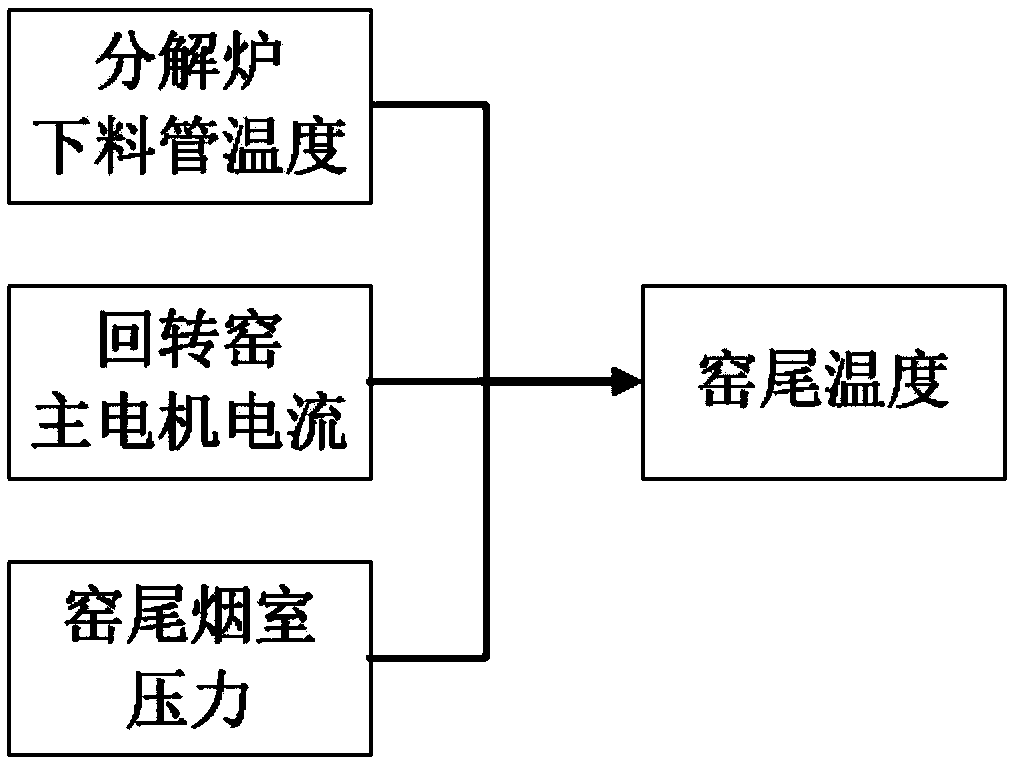

[0082] Figure 7 It is the effect diagram of the kiln tail temperature prediction model, the real-time learning database is 300, and the least squares support vector machine parameters are: γ=10, δ=10.

Embodiment 3

[0084] Figure 8 It is the effect diagram of the kiln head temperature prediction model, the real-time learning database is 300, and the least squares support vector machine parameters are: γ=20, δ=5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com