Air-electrode material of middle- and low-temperature solid oxide fuel cell and preparation method thereof

A solid oxide, fuel cell technology, used in fuel cells, battery electrodes, chemical instruments and methods, etc., can solve problems such as structural stability to be improved, achieve good ionic and electronic conduction characteristics, and improve ionic and electronic conductivity. , the effect of good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

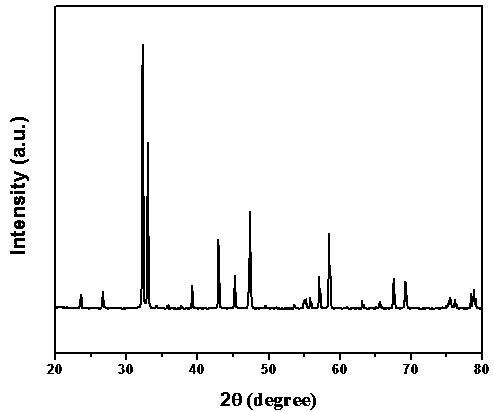

[0024] The preparation method of the air electrode material is as follows: the improved citric acid combustion method is used to prepare powder, and the improved citric acid combustion method is to add an appropriate amount of complexing agent ethylenediaminetetraacetic acid to the traditional citric acid combustion method, Weigh the chemical raw materials corresponding to each element according to the molar ratio of La:Sr:Fe:Ni=0.25:2.75:1:1, add citric acid and ethylenediaminetetraacetic acid (EDTA) two complexing agents, and then add Dissolve nitric acid and ammonia water, adjust the pH to 7-8, evaporate to dryness and sinter to form a powder, and then pre-fire at 1200°C for 3 hours to obtain the air electrode material powder.

[0025] Concrete preparation steps:

[0026] (1) First calculate the required raw material according to the molar mass of each element: La(NO 3 ) 3 ·6H 2 O, Sr(NO 3 ) 2 , Fe(NO 3 ) 3 9H 2 O, Ni(NO 3 ) 3 ·6H 2 The quality of O, and four kin...

Embodiment 1

[0028] Embodiment 1: weigh La (NO 3 ) 3 ·6H 2 O, Sr(NO 3 ) 2 , Fe(NO 3 ) 3 9H 2 O, Ni(NO 3 ) 3 ·6H 2 O is the raw material, and then weigh the complexing agent citric acid and ethylenediaminetetraacetic acid, wherein the molar ratio of citric acid: ethylenediaminetetraacetic acid: metal ion (La+Sr+Fe+Ni) is 1:0.8:1. Put it into a clean beaker, then add 50-100ml of distilled water, then add 15-20ml of nitric acid, stir, ultrasonically dissolve citric acid and EDTA as much as possible, then add ammonia water, adjust the pH to 7-8, and stir at a constant speed to obtain a clear solution.

[0029] Heat the prepared clear solution in an evaporating dish, concentrate until it evaporates to dryness and starts to burn, stop heating to obtain a powder, then put it into a muffle furnace for pre-calcination at 1200°C-3h, remove organic matter, and obtain La 0.25 Sr 2.75 FeNiO7-δ Powder.

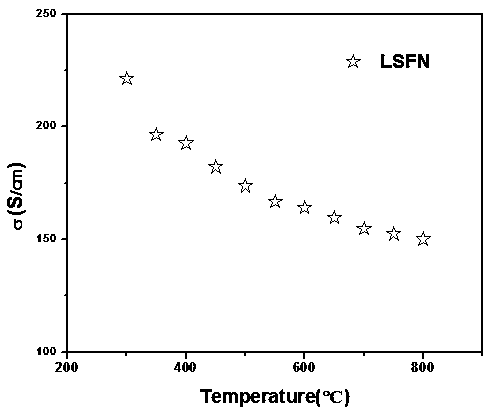

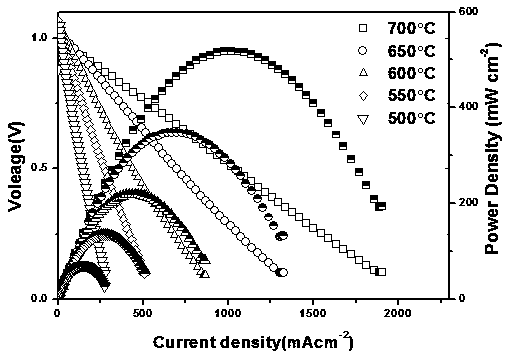

[0030] La 0.25 Sr 2.75 FeNiO 7-δ Add appropriate amount of terpineol containing 10% e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap