Ceramic raw material rough crushing device

A ceramic raw material and coarse crushing technology, applied in grain processing and other directions, can solve the problems of raw material grinding failure, stuck in the coarse crusher, and reduce the coarse crushing efficiency of the coarse crusher, so as to improve the grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further detailed explanation through specific implementation mode below:

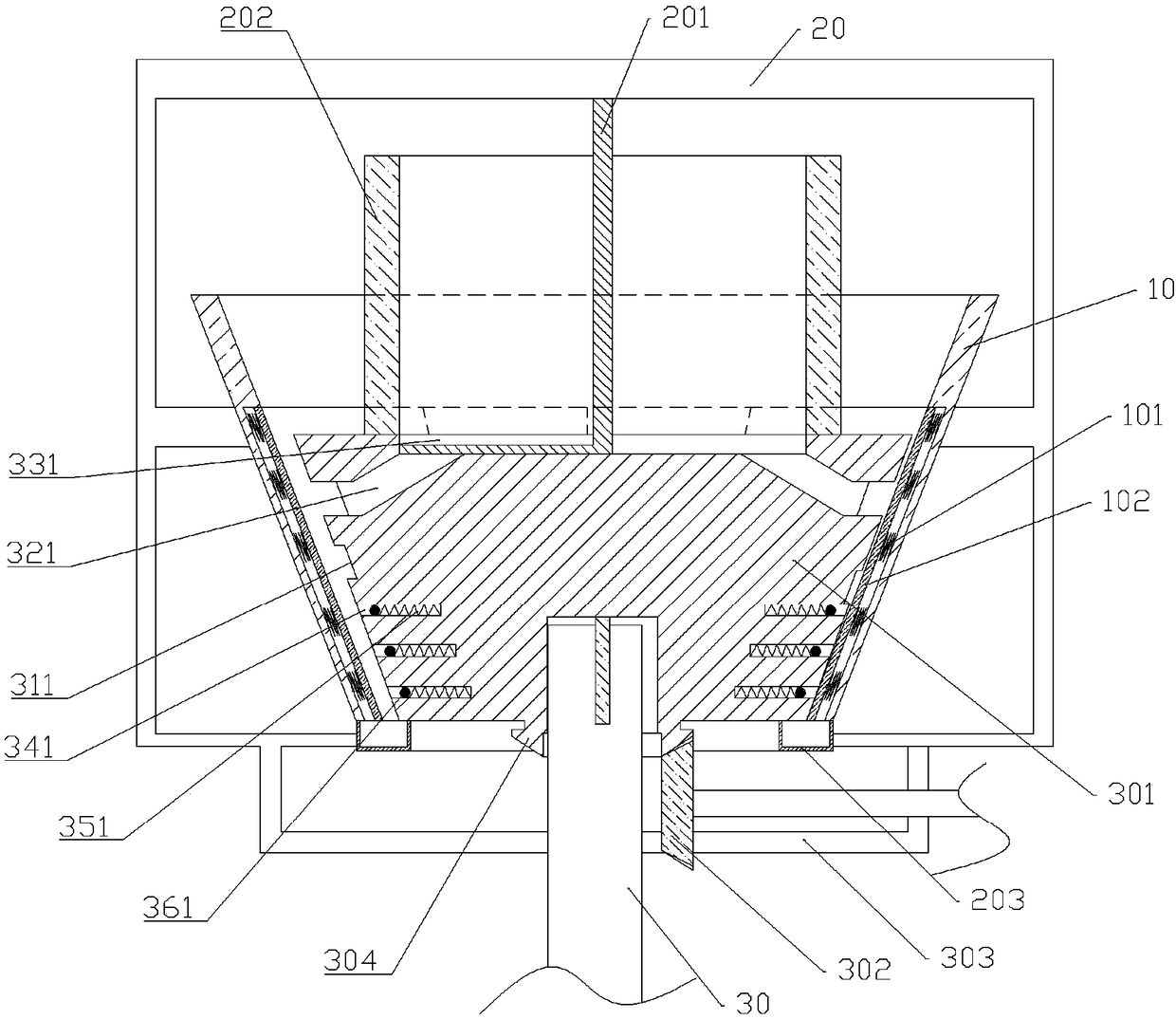

[0018] The reference signs in the accompanying drawings of the description include: housing 10, first spring 101, grinding plate 102, mounting frame 20, driving rod 201, feeding cylinder 202, annular collection tank 203, support rod 30, grinding head 301, screw Slot 311 , through hole 321 , receiving slot 331 , installation slot 341 , second spring 351 , electromagnet 361 , first bevel gear 302 , rotating shaft 303 , and second bevel gear 304 .

[0019] The embodiment is basically as attached figure 1 Shown: a ceramic raw material coarse crushing device, including a housing 10, a mounting frame 20, a lever 201, a feeding cylinder 202, an annular collecting tank 203 and a grinding mechanism, the housing 10 is welded on the mounting frame 20, and the housing 10 is a circular platform shape, and the end of the housing 10 with a smaller diameter faces downward, and the lower end of the housing 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com