Maintenance monitoring and quality evaluation method and system for concrete prefabricated members

A technology of quality evaluation and prefabricated components, applied in manufacturing tools, ceramic molding machines, etc., can solve problems such as complex operations and large errors, and achieve the effects of insufficient monitoring, full-process evaluation of maintenance quality, and real-time control of the entire process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

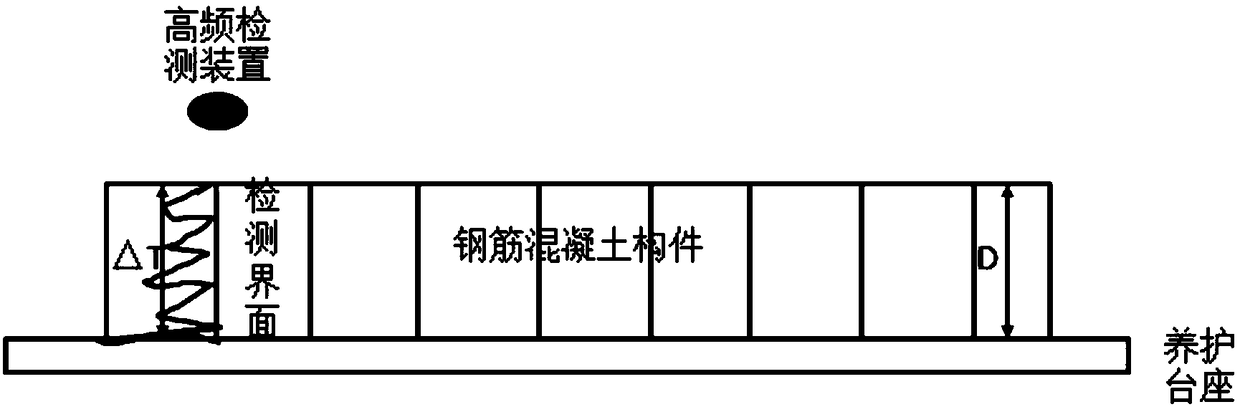

[0043] Such as figure 1 As shown, the present invention provides a method for monitoring and quality evaluation of prefabricated concrete components, including:

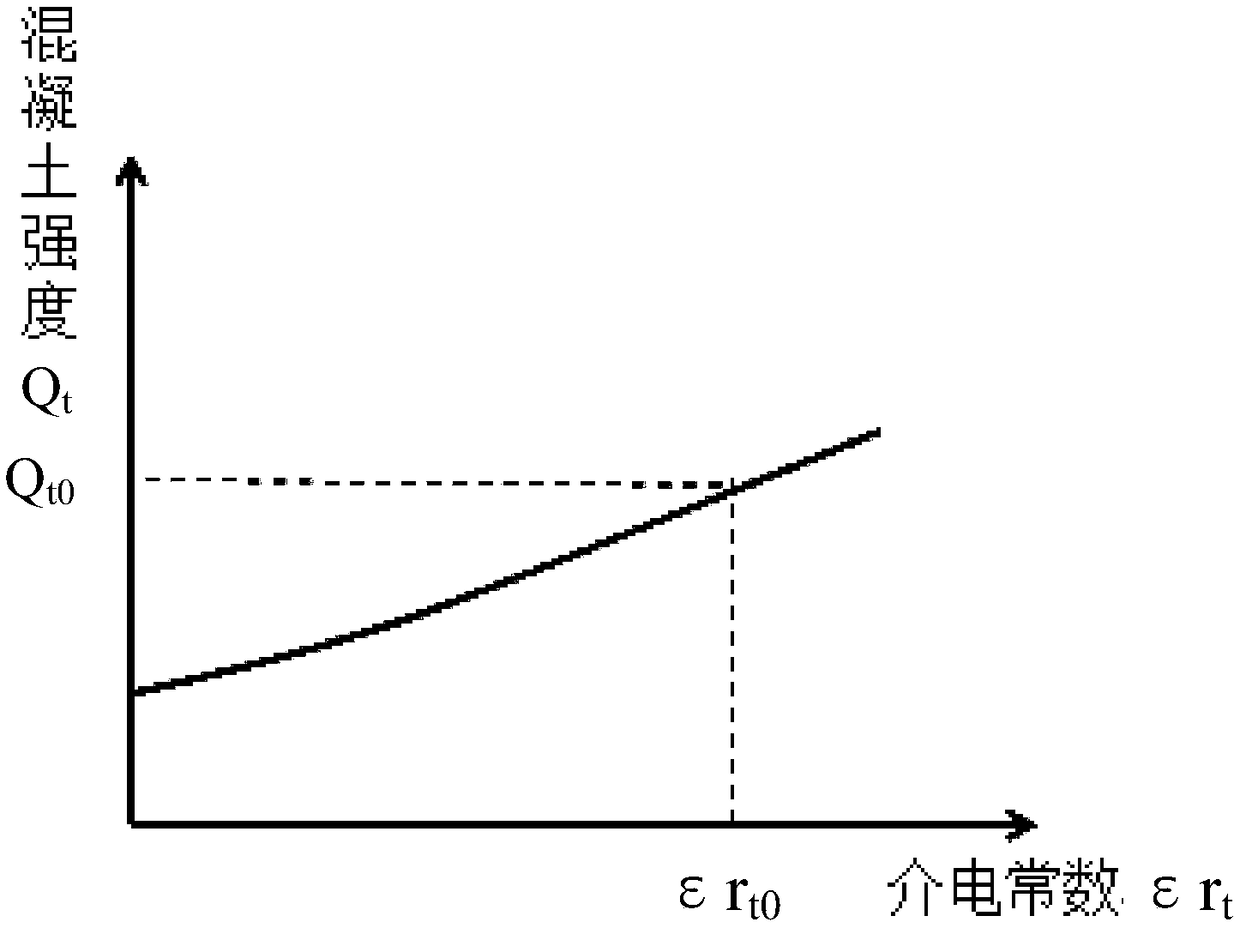

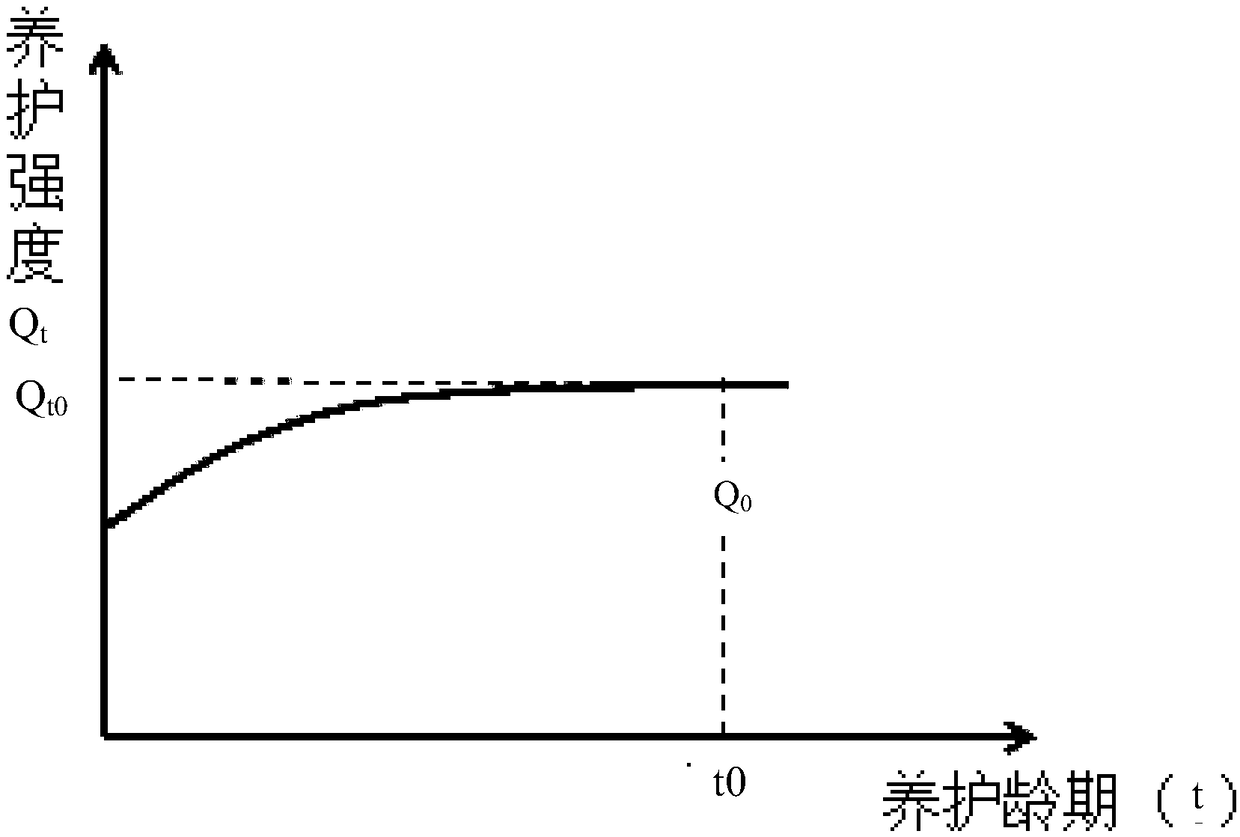

[0044] Step S1, establish the target concrete strength Q of concrete members under standard curing conditions, a certain concrete ratio and reinforcement ratio, and each curing age t t0 and permittivity εr t0 corresponding relationship;

[0045] Step S2, establishing the target concrete strength Q of the concrete members under each curing age t under the standard curing conditions t Corresponding concrete moisture content (or curing humidity) W t and the electric coefficient εr of the concrete member t The relationship curve, according to the relationship curve to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com