Stapleless stapler

A stapler and punching pin technology, applied in binding and other directions, can solve the problems of destroying the orderliness of original documents, tearing of paper fixing holes, and consumption of staples, so as to facilitate popularization and use, reduce resource consumption, and prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

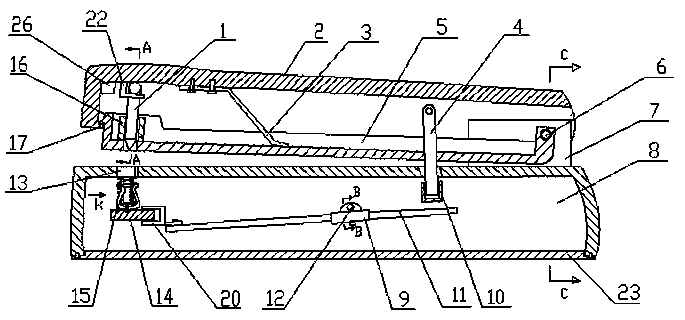

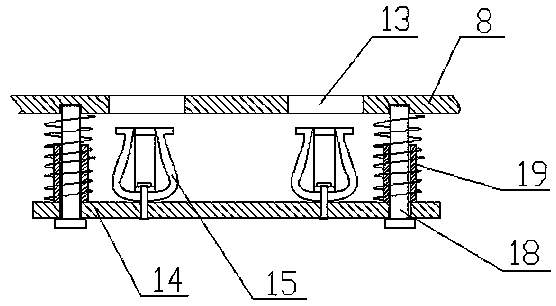

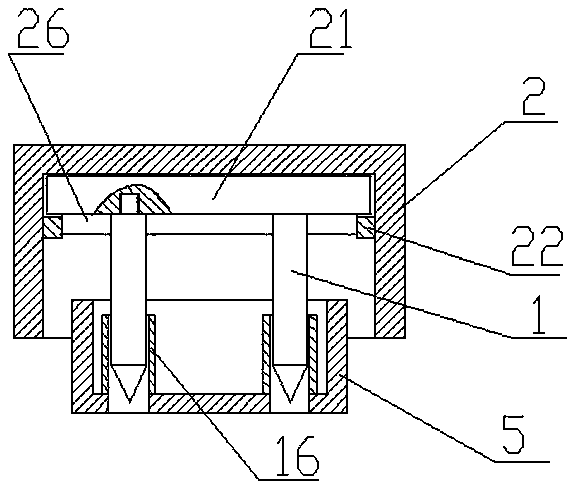

[0032] refer to figure 1 — Figure 13, a needleless stapler, including a gland and a base, the gland is located above the base, a paper pressing groove 5 is set in the inner cavity of the gland 2, the end of the gland 2, the paper pressing groove and the base 8 The ends are hinged together by the same pin shaft 6. The gland 2 is a lid with an open lower end. A leaf spring 3 is arranged in the inner cavity of the gland 2, and the upper end of the leaf spring is fixedly connected to the top surface of the gland 2. , the lower end of the plate spring 3 leans against the inner bottom surface of the paper press groove 5, and a punch support shaft is mounted on the top of the inner cavity of the cover 2, and two pin support shafts are vertically fixed on the outer peripheral surface of the punch support shaft 21. Two alternate tines 1, the tines support shaft 21 and the axes of the two tines 1 are on the same plane, the paper pressing groove 5 is a groove body with an open upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com