Striding type loading and unloading equipment special for railway containers and operation method

A technology for loading and unloading equipment and containers, which is used in transportation and packaging, trolley cranes, load hanging components, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with accompanying drawings and several typical embodiments, and other special loading and unloading equipment for railway containers of various structural types can be equivalently transformed or combined by addition and subtraction of structural components by the technical solutions of this specification and these typical embodiments It can be concluded that the special loading and unloading operation methods of railway containers in other various modes can be obtained by the technical scheme of this manual and these typical embodiments equivalent transformation or selection change of equipment type, selection increase or decrease combination of operation steps, etc. Within the protection scope of the present invention.

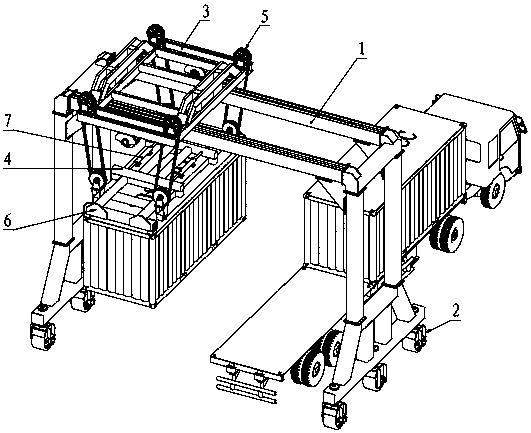

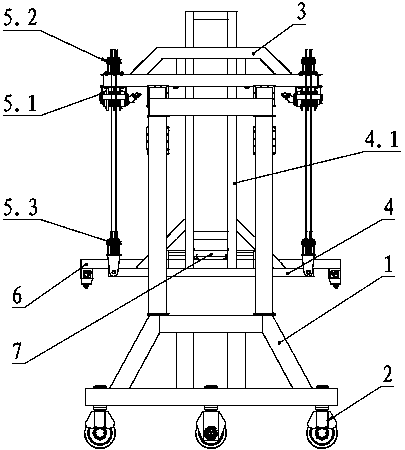

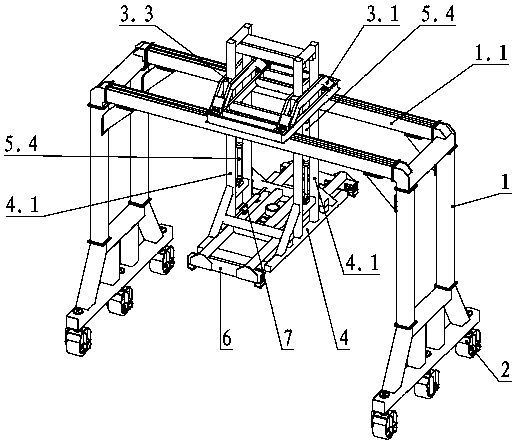

[0058] The first embodiment of the present invention is Figure 1-4 As shown, a special loading and unloading equipment for straddling railway containers is a basic structural type, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com