Automatic sewage transfer station

A transfer station, sewage technology, applied in the direction of light water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. problem, to achieve the effect of volume reduction, weight reduction, and good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

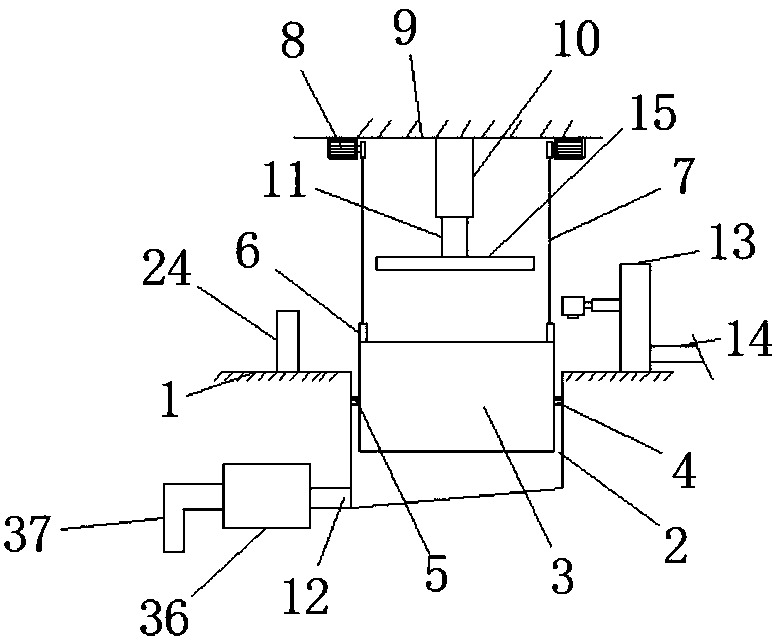

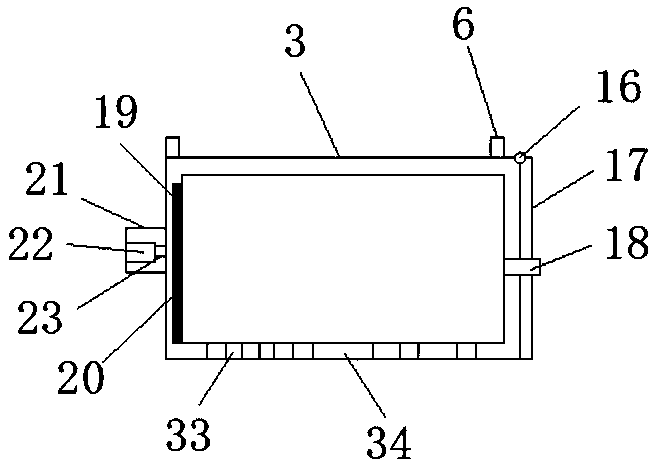

[0028] refer to Figure 1-6 , an automatic sewage transfer station, including a ground 1, a box body 3, a sewage pipe 12, a pressure plate 15, a second hydraulic cylinder 22 and a third hydraulic cylinder 29, the top of the ground 1 is provided with a groove 2, and the concave The inner cavity of the groove 2 is provided with a box body 3, and the left and right side walls of the box body 3 are equipped with a placement block 5, and the left and right side walls of the inner cavity of the groove 2 are equipped with a limit block 5, and the placement block 4 is placed on the top of the limit block 5, and the four corners of the top of the box body 1 are equipped with connecting blocks 6, and the top of the connecting block 6 is connected with one end of a connecting rope 7, and the other end of the connecting rope 7 is connected to At the outer end of the drive shaft of the motor 8, the motor 8 is mounted on the top of the wall 9, the middle of the top of the wall 9 is equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com