A kind of fiber-reinforced cement-based material and preparation method thereof

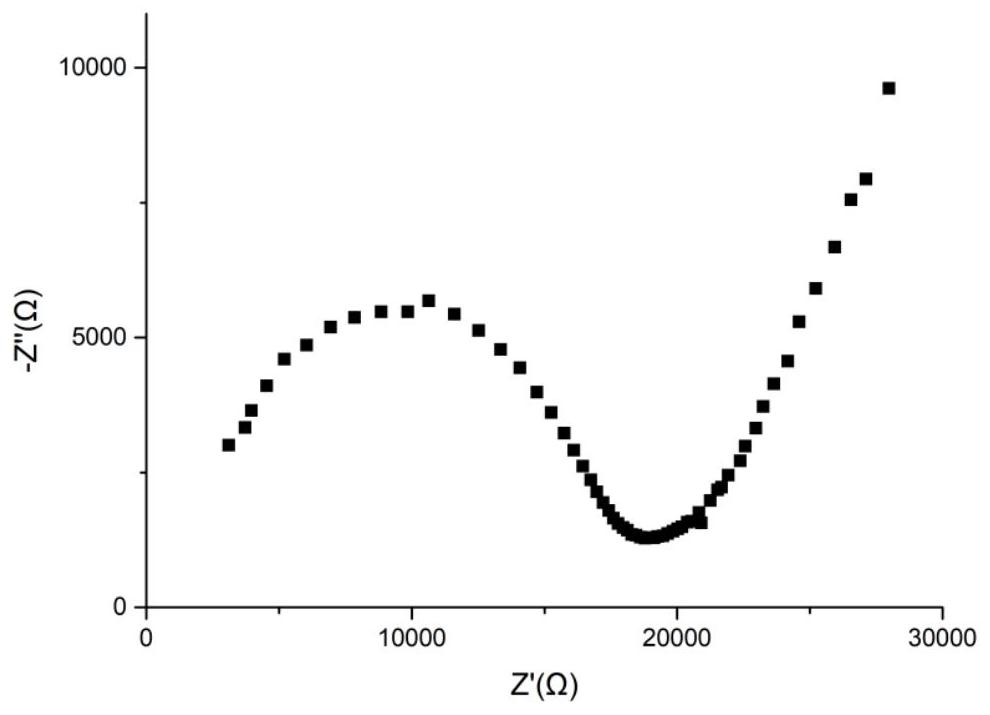

A fiber reinforced cement and base material technology, applied in the field of building materials, can solve the problem that the applicability of ultra-high performance fiber reinforced cement base materials is not known, and achieve the effect of large resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

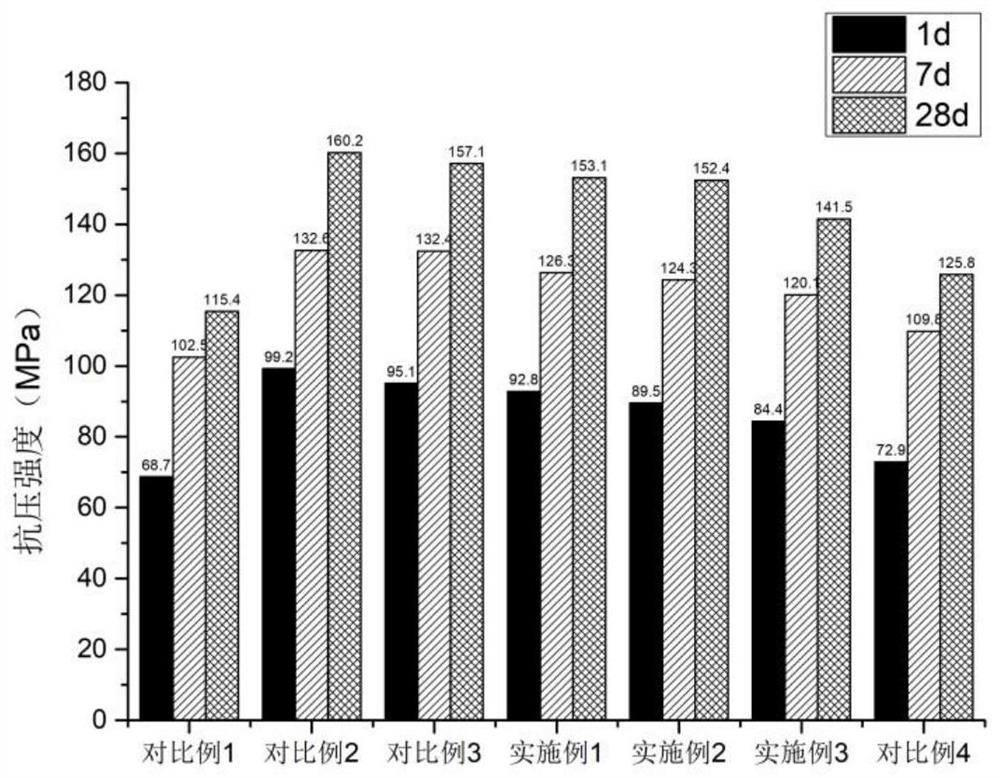

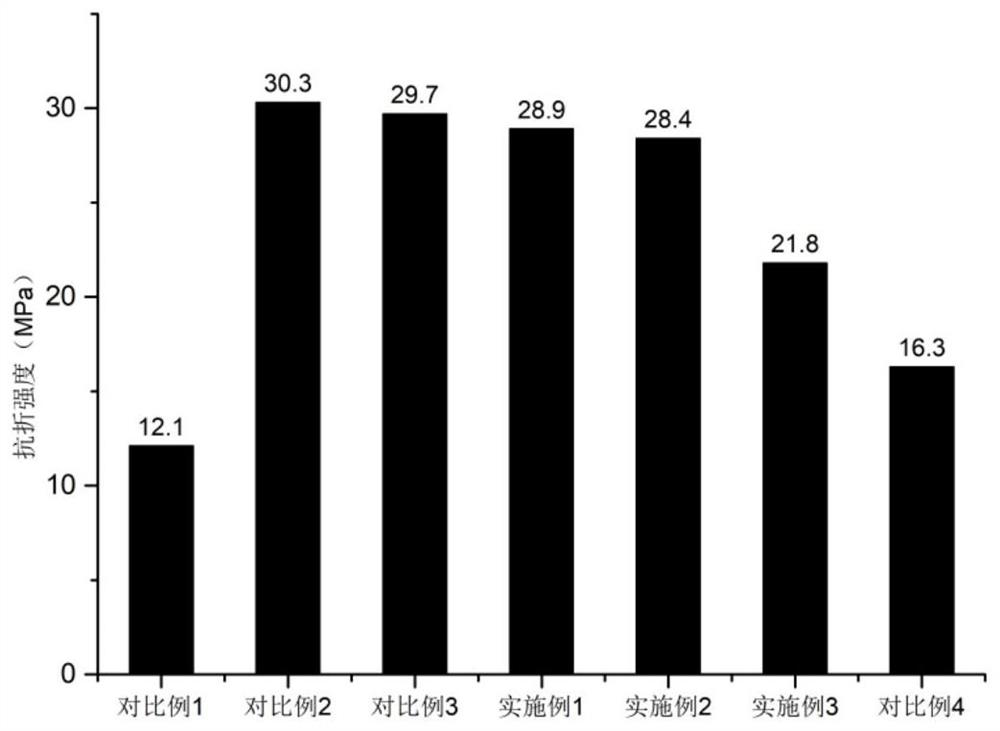

Embodiment 1

[0029] The ratio of raw materials in this embodiment is shown in Table 1. In this embodiment, the volume ratio of the steel fiber SF and the pure basalt fiber BF is 3:1. The volume dosage of steel fiber SF is 1.5%, and the volume dosage of basalt fiber is 0.5%. Among them, according to the density of steel 7.8g / cm 3 And the density of basalt is 2.7g / cm 3 , the mass of fiber per cubic meter in each ratio can be calculated, that is, the mass of steel fiber and pure basalt fiber is given in Table 1.

Embodiment 2

[0031] The ratio of raw materials in this embodiment is shown in Table 1. In this embodiment, the volume ratio of steel fiber SF and pure basalt fiber BF is 1:1. The volume dosage of steel fiber SF is 1%, and the volume dosage of pure basalt fiber is 1%.

Embodiment 3

[0033] The ratio of raw materials in this embodiment is shown in Table 1. In this embodiment, the volume ratio of the steel fiber SF and the pure basalt fiber BF is 1:3. The volume dosage of steel fiber SF is 0.5%, and the volume dosage of pure basalt fiber is 1.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com