Method for extracting cellulose from straw

A cellulose and straw technology, which is applied in cellulose raw material pulping, fiber raw material, fiber raw material processing and other directions, can solve the problems of low utilization rate, fire hazard, environmental pollution, etc., and achieve the effect of low processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

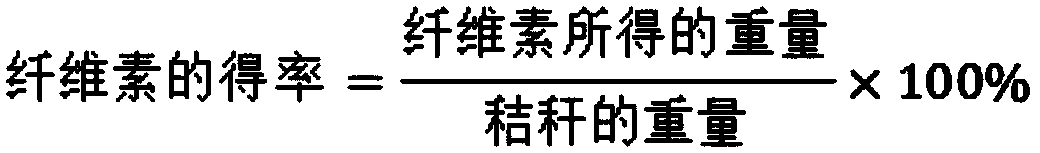

Examples

Embodiment 1

[0027] A method for extracting cellulose from straw, comprising the steps of:

[0028] 1) Pretreatment: remove impurities such as stone and soil from 5 g of straw, remove leaves and cut into small sections, wash and dry at 70-80° C. for 1-2 hours to obtain cleaned straw; The straw is crushed and passed through a 40-60 mesh sieve to obtain straw powder;

[0029] 2) Mix the straw powder and 5% aqueous sodium hydroxide solution in a mass ratio of 1:8 and soak for 48 hours to obtain the first mixed solution;

[0030] 3) Subjecting the first mixed solution to steam explosion treatment for 3 minutes under the condition of pressure ≥ 0.04Mpa, then filtering, drying the filter residue at 70-80°C for 1-2 hours to obtain a pretreated product;

[0031] 4) Mix the pretreated substance and 3-methyl-N-butylchloropyridine solution in a mass ratio of 1:10, and stir at 50°C for 5 hours; then filter to obtain the second mixed solution ;

[0032] 5) Concentrate and dry the second mixed soluti...

Embodiment 2

[0035] A method for extracting cellulose from straw, comprising the steps of:

[0036] 1) Pretreatment: Remove impurities such as stones and soil from 5 g of straw, remove leaves and cut into small sections, wash and dry at 80° C. for 2 hours to obtain cleaned straw; crush the cleaned straw , and passed through a 50-mesh sieve to obtain straw powder;

[0037] 2) Mix the straw powder and 5% sodium hydroxide solution at a mass ratio of 1:8 and soak for 48 hours; obtain the first mixed solution;

[0038] 3) Subjecting the first mixed solution to steam explosion treatment for 3 minutes under the condition of pressure ≥ 0.04 Mpa, then filtering, and drying the filter residue at 70° C. for 1 hour to obtain a pretreated product;

[0039] 4) Mix the pretreated substance and 3-methyl-N-butylchloropyridine solution in a mass ratio of 1:10, and stir at 50°C for 5 hours; then filter to obtain the second mixed solution ;

[0040] 5) Concentrate and dry the second mixed solution, wash wi...

Embodiment 3

[0042] 1) Pretreatment: remove impurities such as stones and soil from 5 g of straw, remove leaves and cut into small sections, wash and dry at 75° C. for 2 hours to obtain cleaned straw; crush the cleaned straw , and passed through a 50-mesh sieve to obtain straw powder;

[0043] 2) Mix the straw powder and 5% sodium hydroxide solution at a mass ratio of 1:8 and soak for 48 hours; obtain the first mixed solution;

[0044] 3) subjecting the first mixed solution to steam explosion treatment for 3 minutes under the condition of pressure ≥ 0.04 Mpa, then filtering, and drying the filter residue at 75° C. for 1 hour to obtain a pretreated product;

[0045] 4) Mix the pretreated substance and 3-methyl-N-butylchloropyridine solution in a mass ratio of 1:10, and stir at 50°C for 5 hours; then filter to obtain the second mixed solution ;

[0046] 5) Concentrate and dry the second mixed solution, wash with deionized water for 5 times, and dry at 80° C. for 2 hours to obtain a cellulo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com