A microwave power adaptive control system and method for engineering rock mass fracturing

A technology of self-adaptive regulation and microwave power, applied in microwave heating, drilling equipment and methods, earthwork drilling and mining, etc., can solve problems such as impedance mismatch, increase of microwave reflection power, and decrease of microwave energy utilization efficiency, and meet the requirements of Effects of real-time matching, improved stability, and reduced microwave reflected power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

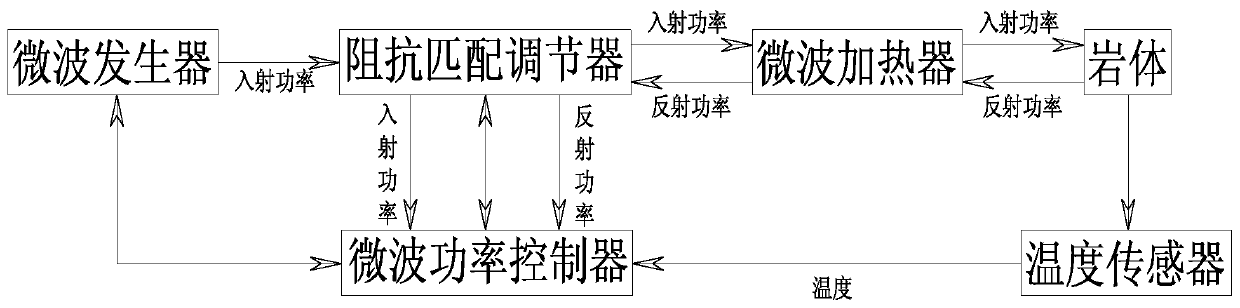

[0016] Such as figure 1 As shown, a microwave power adaptive control system for engineering rock mass fracturing includes an impedance matching regulator, a microwave power controller and a temperature sensor; one end of the impedance matching regulator is used to access the microwave output by the microwave generator, And the incident power of the microwave is recorded in the impedance matching regulator; the other end of the impedance matching regulator is used to output the microwave, and the microwave output from the impedance matching regulator is transmitted to the microwave heater, and then the microwave radiated by the microwave heater has an impact on the rock. After the microwave reflected by the rock mass returns to the impedance matching regulator through the microwave heater, the reflected power of the microwave is record...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com