Welding stud position detection device and method based on silhouette technology

A technology of welding stud and detection device, applied in the field of visual measurement, can solve the problems of low measurement accuracy and low efficiency, and achieve the effects of high measurement accuracy, high calculation efficiency and less calculation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

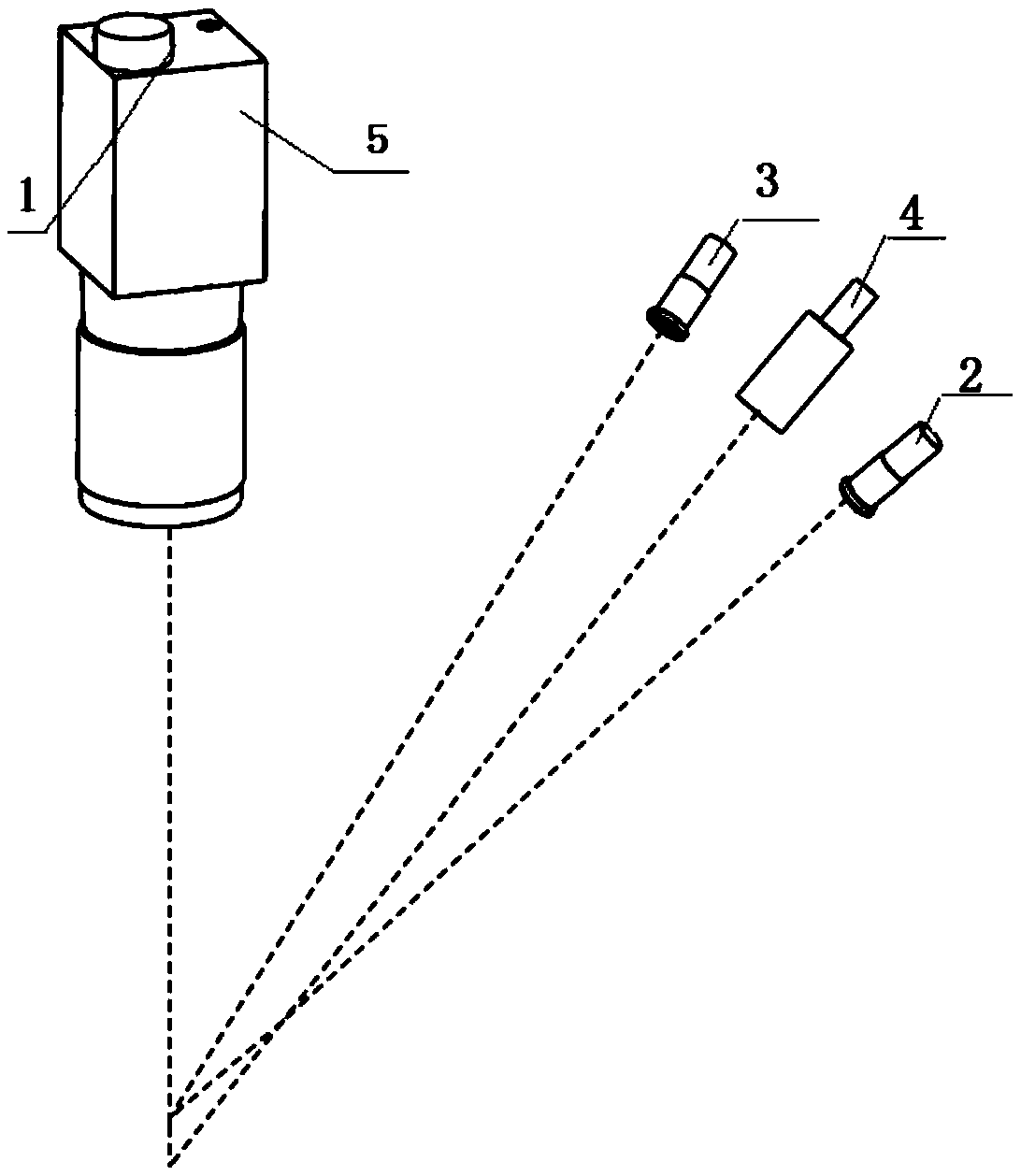

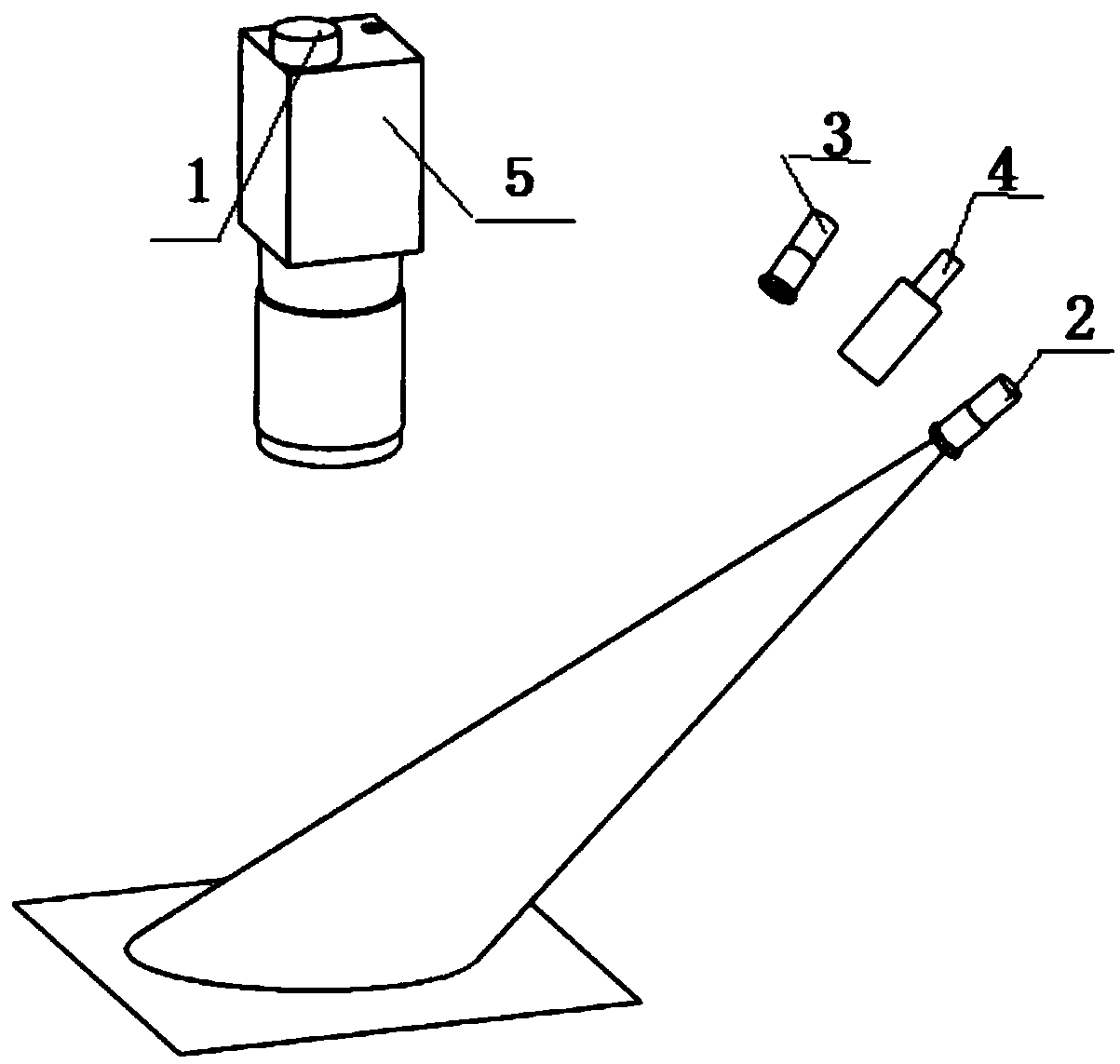

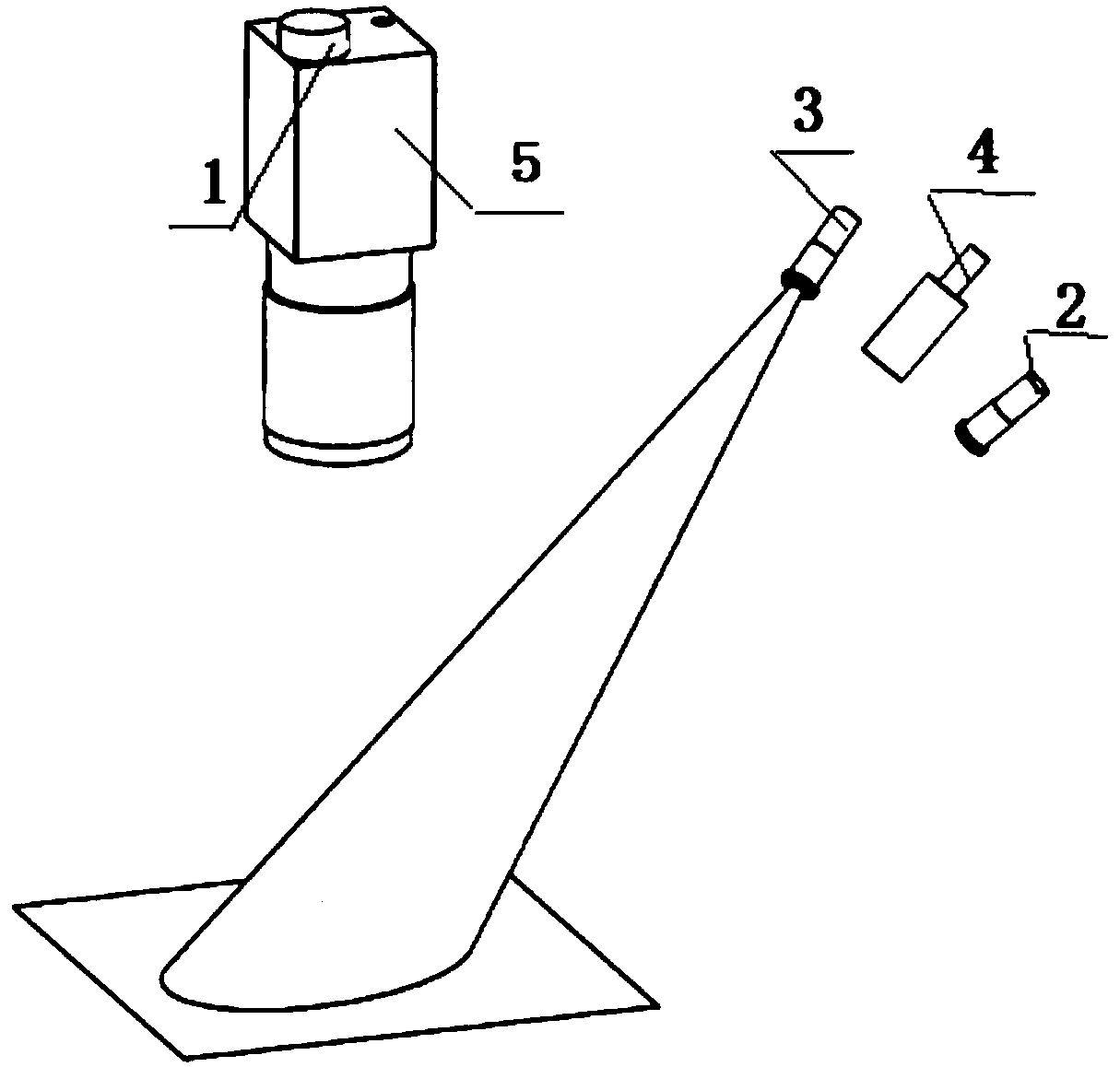

[0038] A welding stud position detection device based on silhouette technology, such as figure 1 As shown, it includes: a camera 1, multiple point light sources and line lasers 4, the optical axis of the camera 1 is perpendicular to the plane where the object to be measured is located; multiple point light sources and line lasers 4 are arranged above the side of the object to be measured; multiple When the point light source is irradiated, the shadows formed by at least two point light sources irradiating the object to be measured are not on the same straight line. The light emitted by multiple point lights is projected at the working distance directly in front of the camera.

[0039] Preferably, the heights of the multiple point light sources are the same, and the angles between the light rays formed by them and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com