Clay adhesion test device with upward soil pushing and extruding effect and adjustable contact area and test method

A technology of contact area and testing device, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problem that the contact area of the test plate cannot be changed, and achieve the effects of uniform loading, uniform contact stress, and adjustable area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below with reference to the accompanying drawings and embodiments.

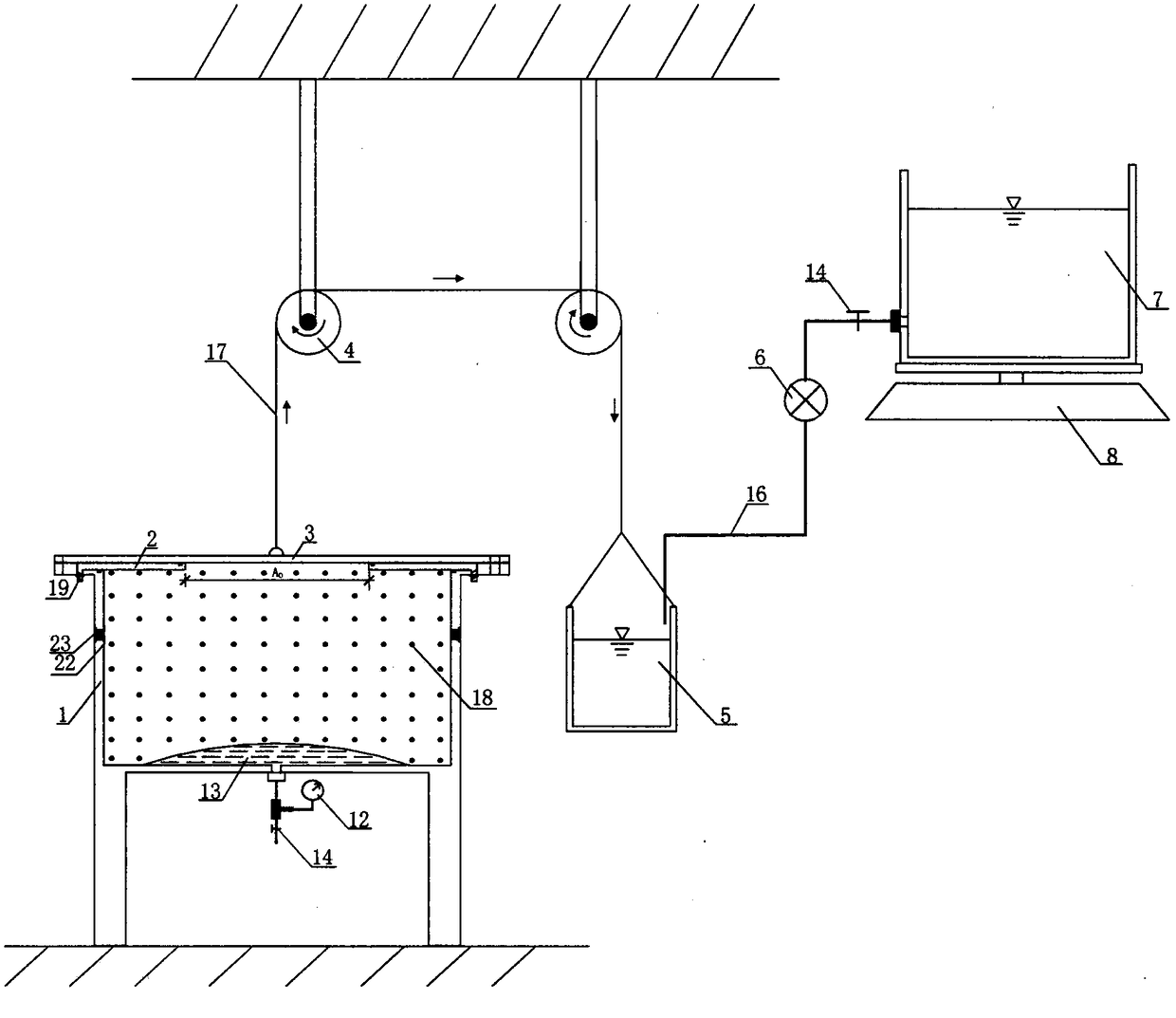

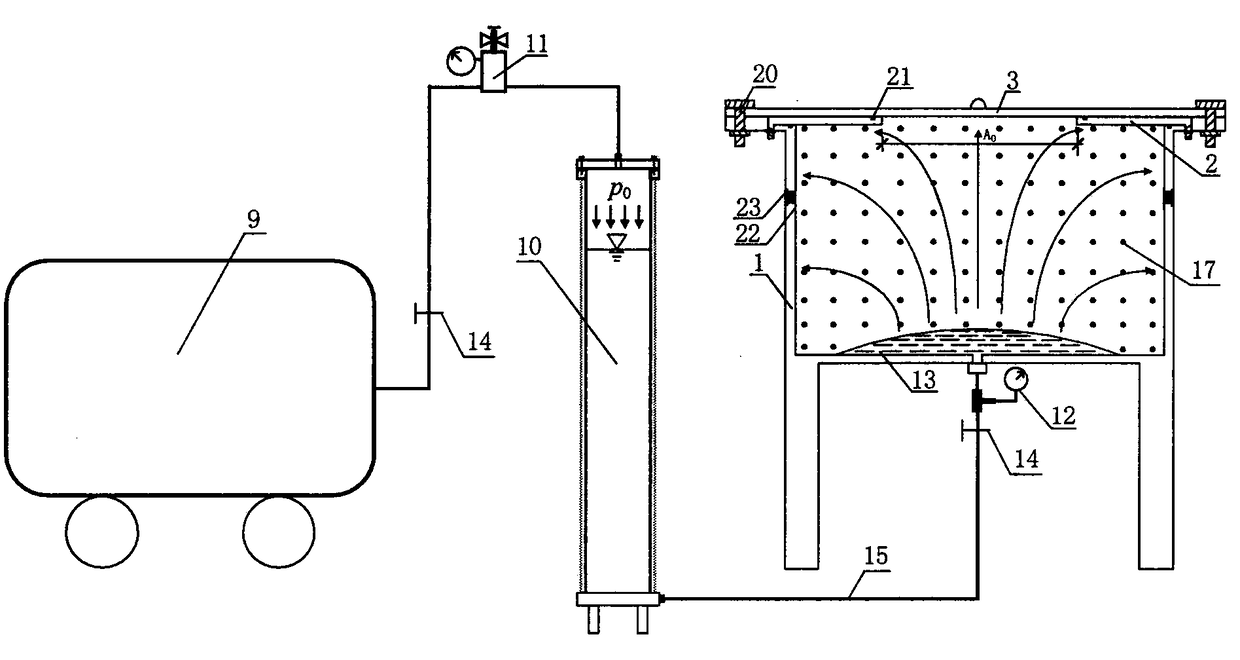

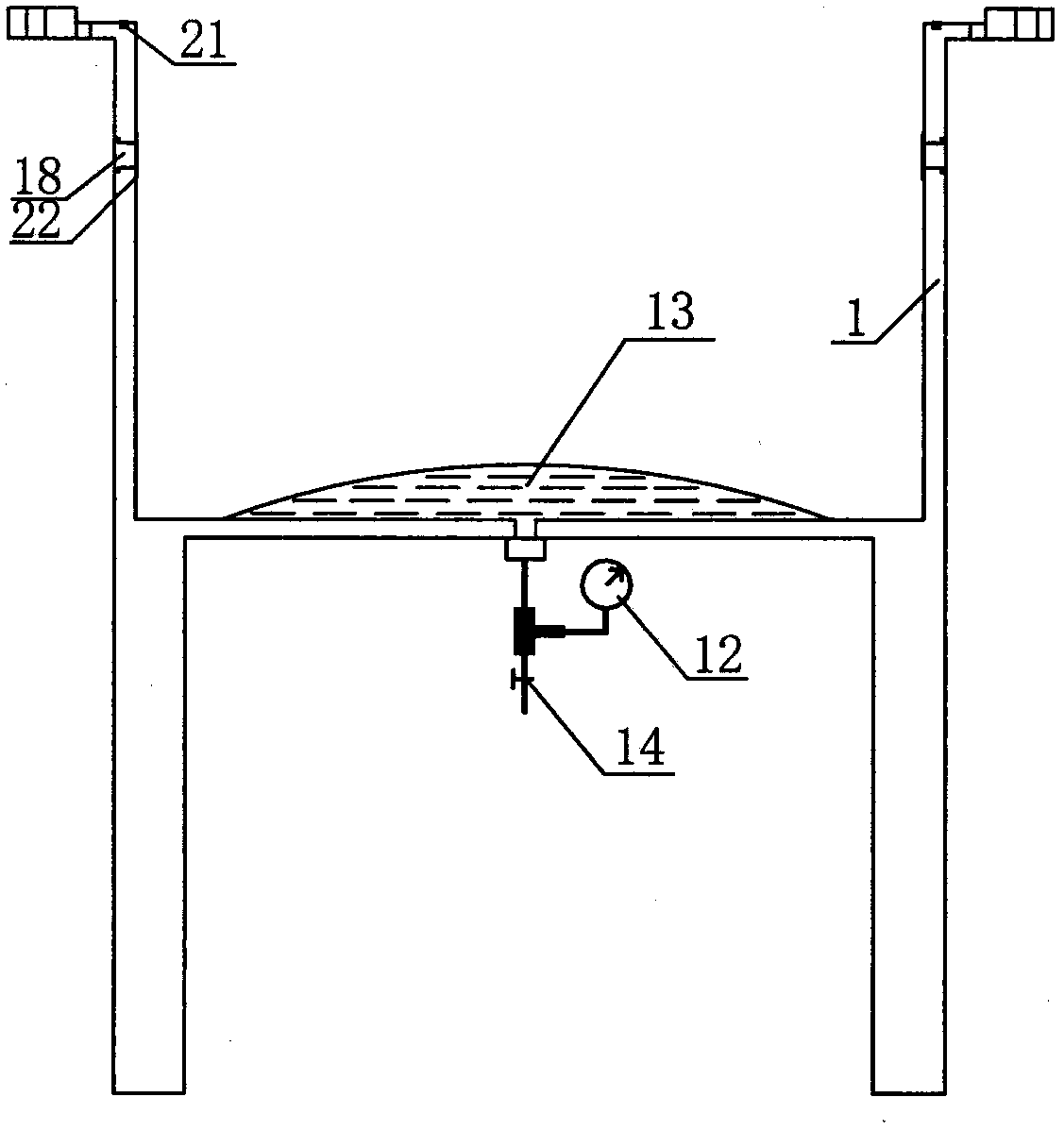

[0041] As shown in Figure 1 - as image 3 As shown in Figure 1, a clay adhesion test device with adjustable contact area for pushing the soil (as shown in Figure 1) consists of a cylindrical soil box 1, an annular metal backing plate 2, a soil box cover 3, a fixed pulley 4, a storage Water bottle 5, flow meter 6, water supply bottle 7, balance 8, air compressor 9, water supply bucket 10, pressure control valve 11, pressure gauge 12, water bladder 13, valve 14, hose 15 and nylon rope 16 are composed together;

[0042] It is characterized in that the annular metal backing plate 2 is fixed on the cylindrical soil box 1 by bolts 19, and the rubber ring 21 at the contact position between the cylindrical soil box 1 and the annular metal backing plate 2 prevents particles and water in the soil sample during the loading process. Enter the contact gap between the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com