Method for equivalently converting fatigue load of large welding structural part

A welding structure and fatigue load technology, applied in the field of efficiency conversion, can solve the problems of long test cycle and high test cost, and achieve the effect of simplifying the test plan, reducing the number of loads and saving the test cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

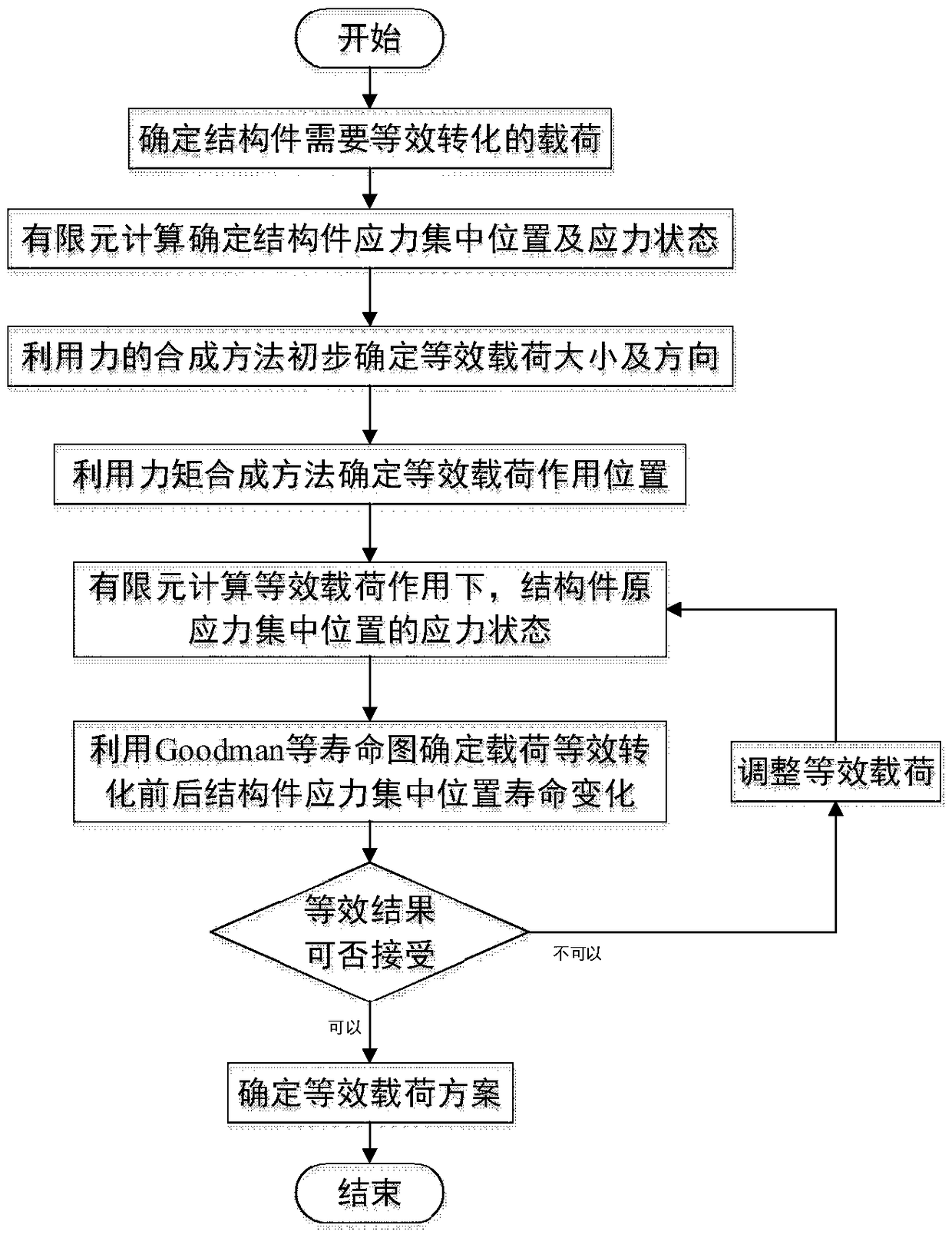

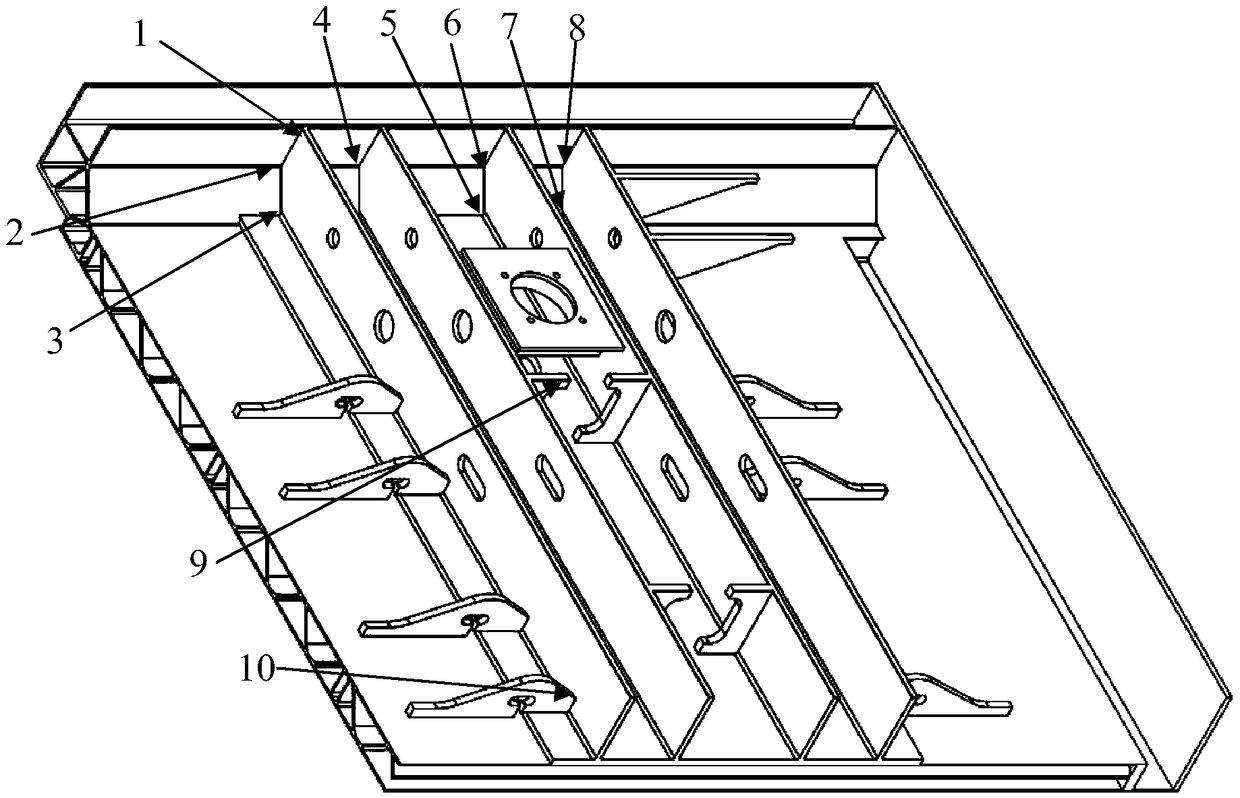

[0032] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

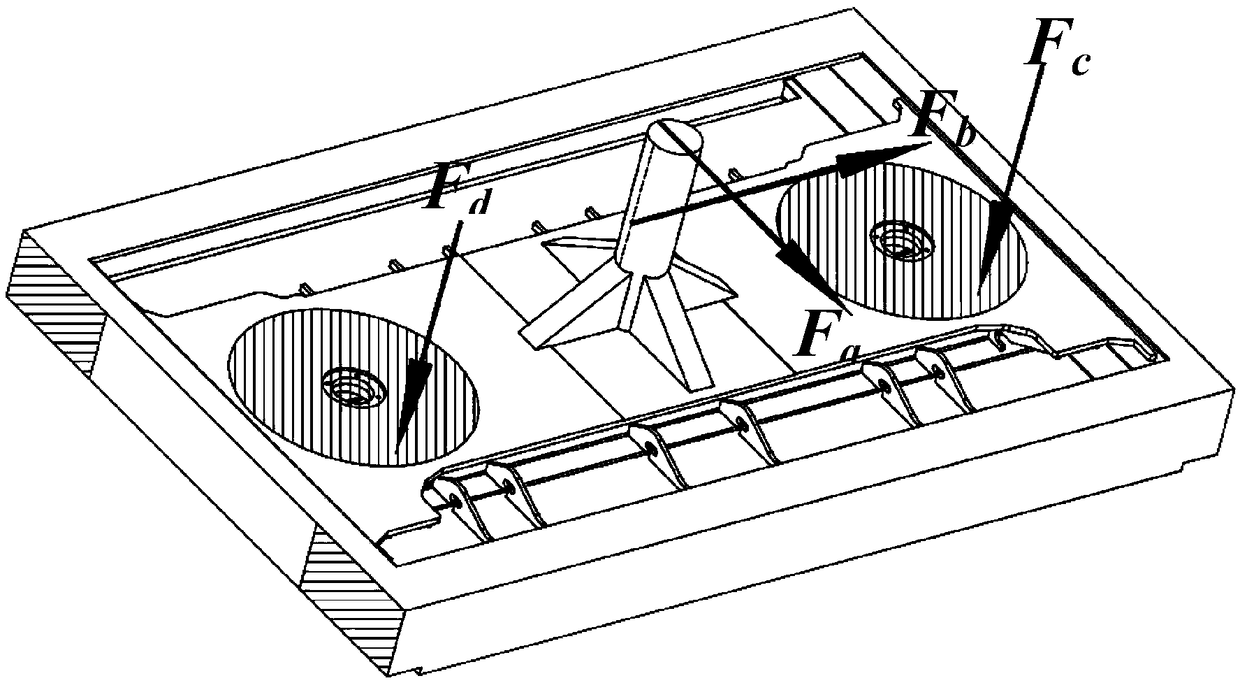

[0033] On the premise that the fatigue life of large welded structural parts remains basically unchanged before and after load equivalent transformation, the method of the present invention utilizes force synthesis, torque synthesis, finite element method and fatigue life diagrams to obtain a structure that can replace multiple loads acting simultaneously A fatigue test load. The specific equivalent process can be briefly described as follows: first determine the load information of large welded structural parts, and use the finite element method to analyze the structural parts to determine the location of stress concentration; then use the combination of force and moment to determine the theoretical equivalent Payload information; finally, use the finite element method and fatigue life diagrams to evaluate the life of the stress concentration locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com