Pressure sensing circuit board and terminal

A technology of circuit boards and terminals, applied in circuits, electric switches, electrical components, etc., can solve problems such as poor waterproof and anti-static discharge performance, inability to quantify pressure, and large thickness of light touch switches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

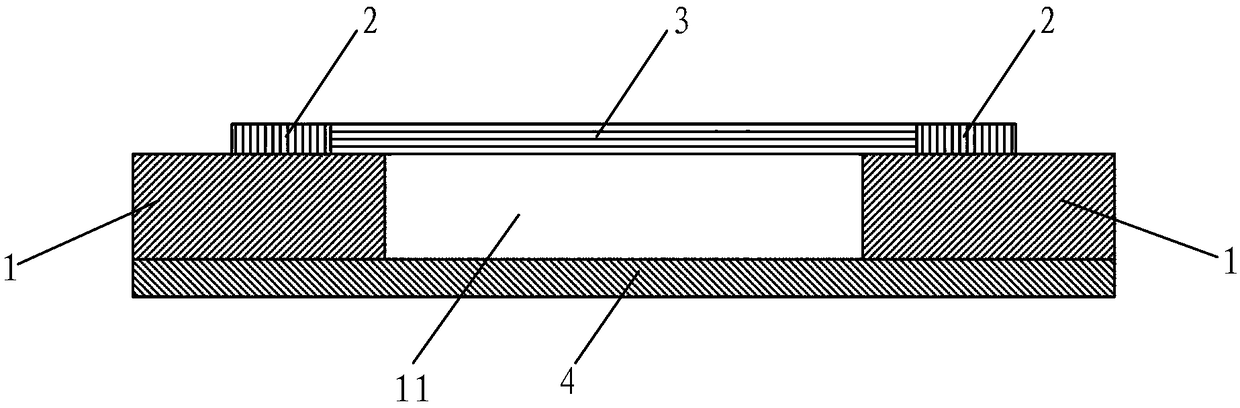

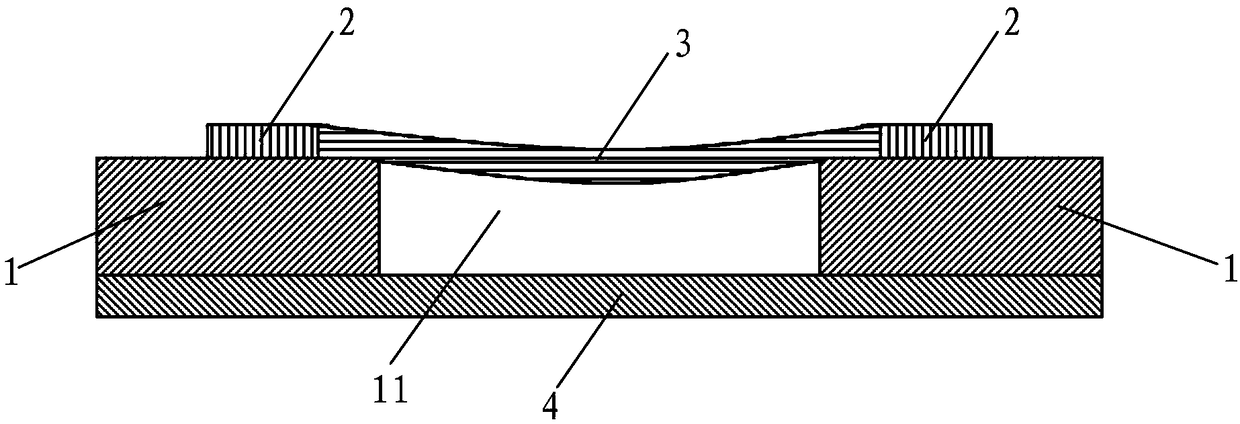

[0035] Embodiment 1: The material of the sensing element 3 is a material having a Hall effect.

[0036] Specifically, the sensing element 3 is made of a material having a Hall effect. Preferably, the outer surface of the inductive element 3 made of a material having a Hall effect does not protrude from the outer surface of the circuit part, such as: the inductive element 3 and the circuit part arranged on the first surface of the insulating plate 1 are in a plane, In order to avoid increasing the overall thickness of the pressure-sensitive circuit board.

[0037] Preferably, the sensing element 3 can be made of graphene or semiconductor materials, such as germanium, silicon, gallium arsenide, indium arsenide, indium antimonide, with a thickness of about 20 μm. It has the characteristics of high mobility (mobility>2900cm2 / V·s), high Hall coefficient and good deformation recovery, and thin thickness to improve the overall sensitivity.

[0038] The depth of the recess 11 on the...

Embodiment 2

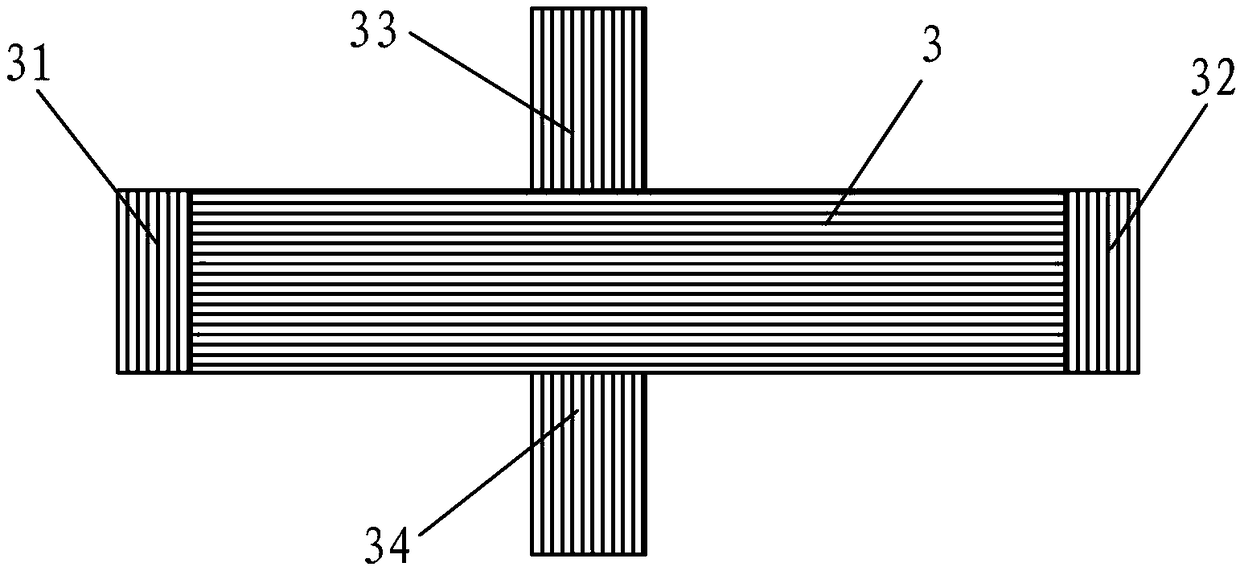

[0052] Embodiment 2: The material of the inductive element 3 is a material with a giant magnetic effect.

[0053] The specific inductive element 3 is made of materials with giant magnetic effect. Preferably, the outer surface of the inductive element 3 made of a material having a giant magnetic effect does not protrude from the outer surface of the circuit part, such as: the inductive element 3 and the circuit part arranged on the first surface of the insulating plate 1 are in a plane, In order to avoid increasing the overall thickness of the pressure-sensitive circuit board.

[0054] Such as Figure 5 , showing an example of an inductive element with giant magnetic effect.

[0055] Wherein, the sensing element 3 includes:

[0056] The first electrode 31 disposed at the first end of the sensing element 3 is connected to one of the positive pole and the negative pole of the power supply. Wherein, the power supply includes but not limited to: a power supply on the pressure-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mobility | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com