Board repairing method based on PCBA board poor welding spot infrared positioning and correcting apparatus

A bad solder joint, infrared technology, applied in the direction of printed circuit maintenance/correction, printed circuit secondary processing, etc., can solve the problems of low work efficiency, low work efficiency, high labor intensity, etc., to improve work efficiency and save correction time. , structurally reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

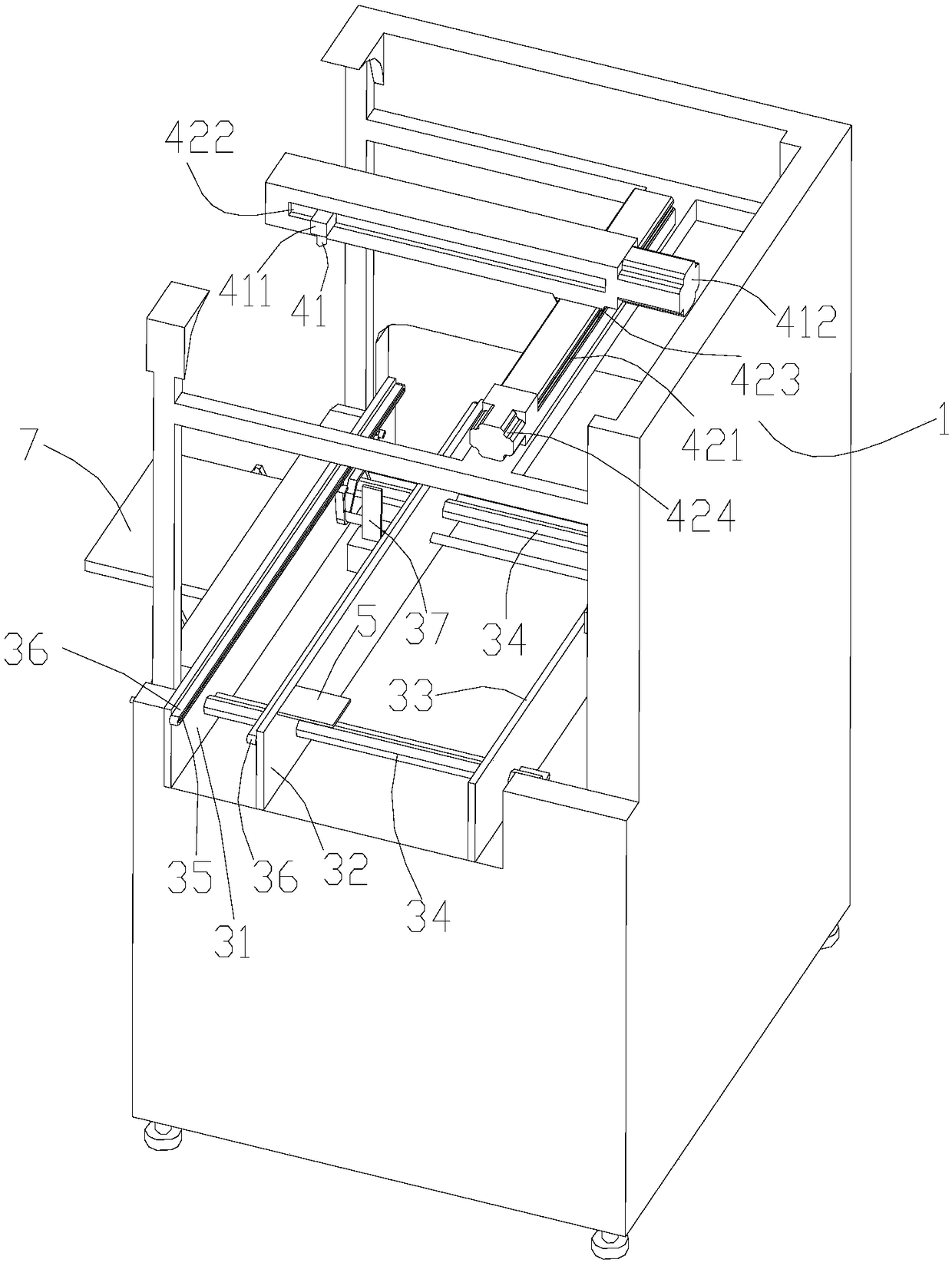

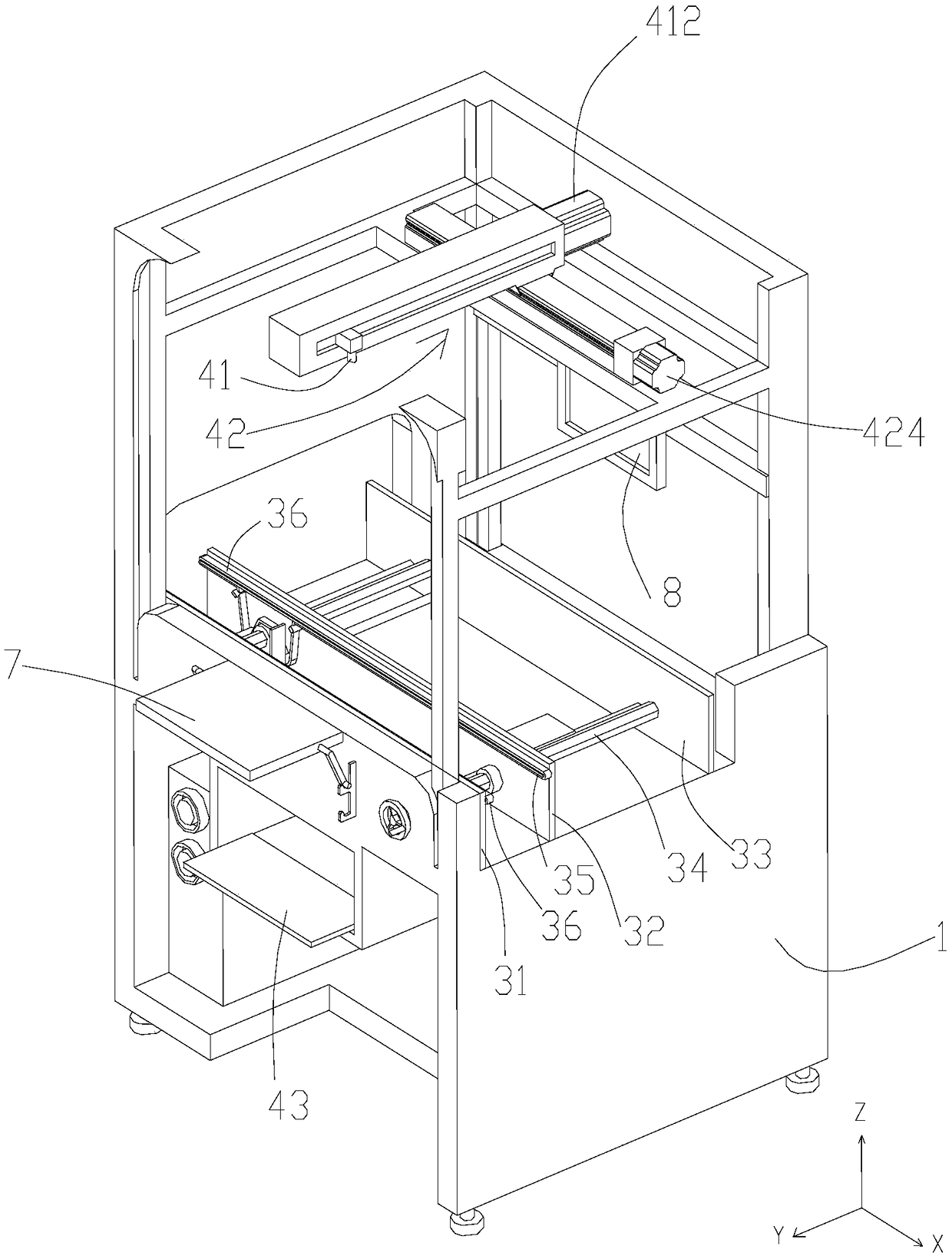

[0023] For the convenience of description, such as image 3 The Chinese text is shown as a reference, defining that the PCBA board flows from the previous process to the next process in the X direction, on the same plane as the X direction, and the direction perpendicular to the X direction is the Y direction; the direction perpendicular to the plane where XY is located is the Z direction.

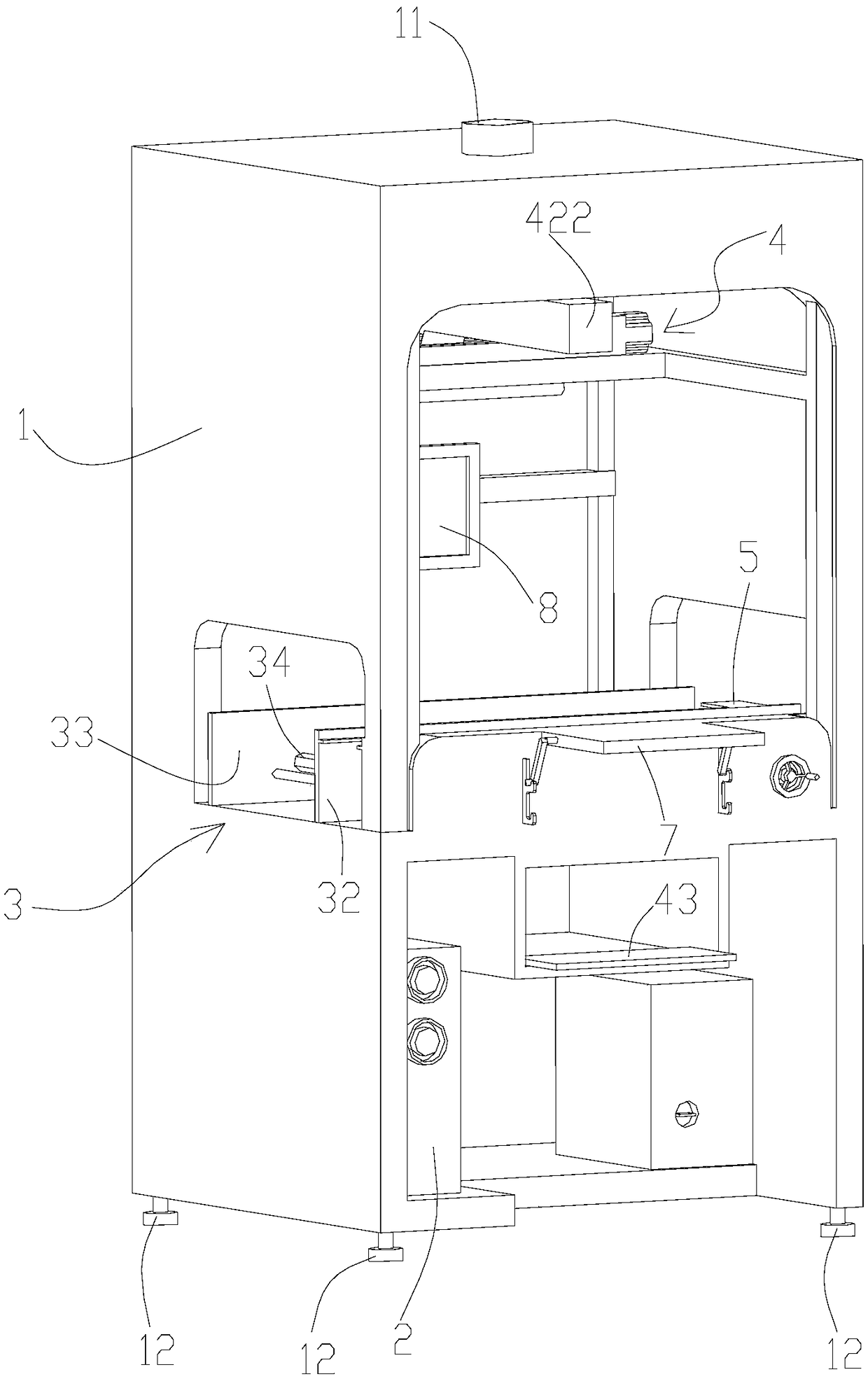

[0024] Such as Figure 1-3 As shown, an infrared positioning correction device for bad solder joints of a PCBA board includes a frame 1, a host computer 2 that stores coordinate information of bad solder joints of a PCBA board to be corrected, an automatic transmission device 3, and can transfer bad solder joints of a PCBA board to be corrected. The infrared positioning system 4 indicated one by one, and the display screen 8 that can display the bad solder spot position image stored in the main frame 2; The main frame 2, automatic transmission device 3, infrared positioning system 4, displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com