Preparation method of quick-frozen fried bread stick flour dough and quick-frozen fried bread stick flour dough

A production method and technology of deep-fried dough sticks, applied in the production of quick-frozen deep-fried dough sticks, and in the field of quick-frozen fried dough sticks, can solve the problems of reduced production efficiency, excessive proofing, and increased production costs, and achieve industrialized processing, improved production efficiency, and soft Moderate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

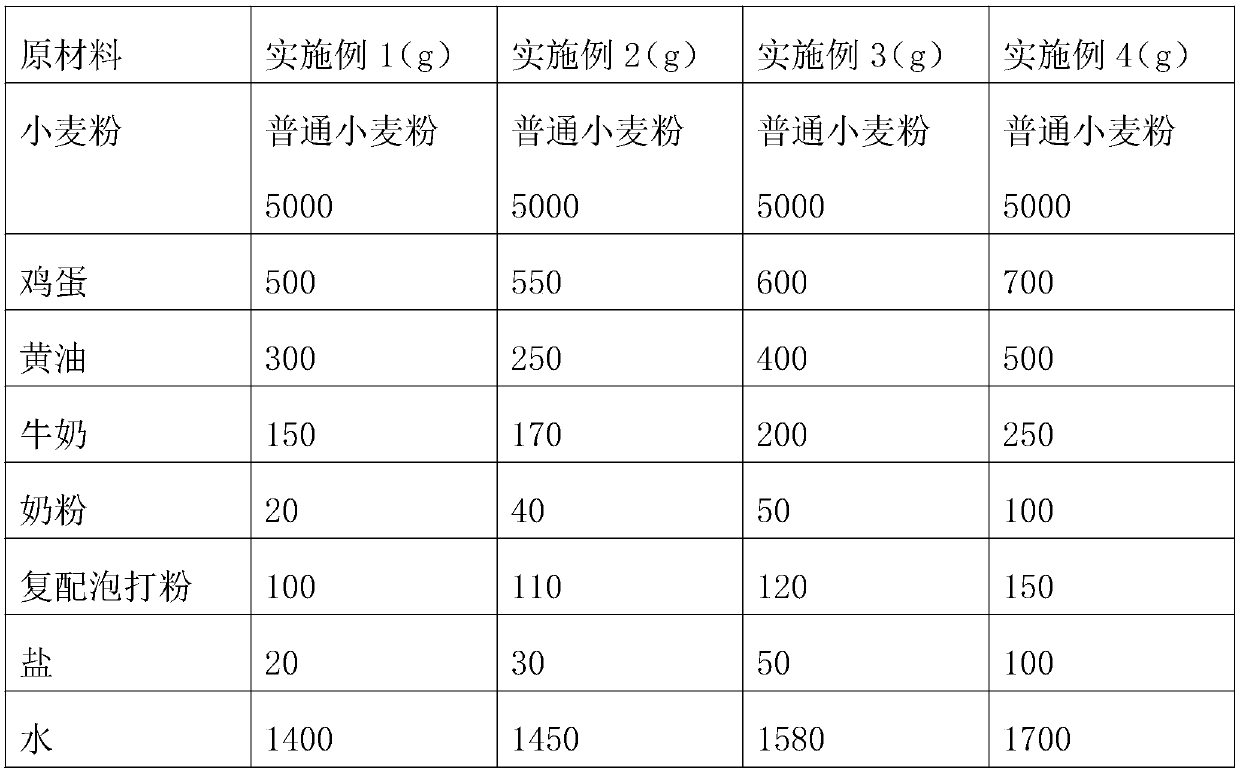

Examples

Embodiment 1

[0033] A method for making quick-frozen fried dough stick dough, comprising the steps of:

[0034] (1) Ingredients: mix the raw materials to make the mixture;

[0035] (2) Kneading dough: add the mixture prepared in step (1) into the dough kneading machine and knead the dough at a stirring speed of 95 rpm, take it out in 20 minutes;

[0036] (3) Proofing at low temperature: Cut the dough prepared in step (2) evenly, wrap the dough into a cylinder about 30 cm long with plastic wrap, and proof at 0°C for 28 hours;

[0037] (4) Noodle pressing: press the dough proofed in step (3) into a strip 60 cm long, 10 cm wide, and 0.3 cm thick;

[0038] (5) Slicing: Cut the strips pressed in step (4) into strips of 10 cm in length, 2 cm in width and 0.3 cm in thickness;

[0039] (6) Lamination: Lay two pieces of noodles together in two layers in the strip noodles cut in step (5), and compact the ends at the first and last ends;

[0040] (7) Packing: packing the finished fried dough stick...

Embodiment 2

[0043] On the basis of Example 1, different from Example 1, the above step (4), step (5) and step (6) select the fried dough stick forming machine prepared by Suzhou Hengyuan Food Machinery Co., Ltd. for pressing, slicing and stacking. Noodles, through the above-mentioned deep-fried dough sticks forming machine, the production capacity is 5000-7000 deep-fried dough sticks per hour.

Embodiment 3

[0045] A method for making quick-frozen fried dough stick dough, comprising the steps of:

[0046] (1) Ingredients: mix the raw materials to make the mixture;

[0047] (2) Kneading dough: add the mixture prepared in step (1) into the dough kneading machine and knead the dough at a stirring speed of 100 rpm, take it out in 15 minutes;

[0048] (3) Proofing at low temperature: Cut the dough prepared in step (2) evenly, wrap the dough into a cylinder about 40 cm long with plastic wrap, and proof at 3 degrees Celsius for 24 hours;

[0049] (4) Noodle pressing: Press the dough that has been proofed at low temperature in step (3) into a strip with a length of 80 cm, a width of 12 cm, and a thickness of 0.5 cm with a dough stick forming machine;

[0050] (5) Slicing: Cut the long strips pressed in step (4) into strip-shaped noodles with a length of 12 cm, a width of 3 cm, and a thickness of 0.5 cm with a fried dough stick forming machine;

[0051](6) Lamination: Use a deep-fried do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com