Strip steel width control method, device and terminal equipment

A technology of width control and width, which is applied in the field of steel hot rolling, can solve the problems of finished strip steel width deviation and low precision of strip steel width, and achieve the effects of precise width, improved yield, and avoiding width deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

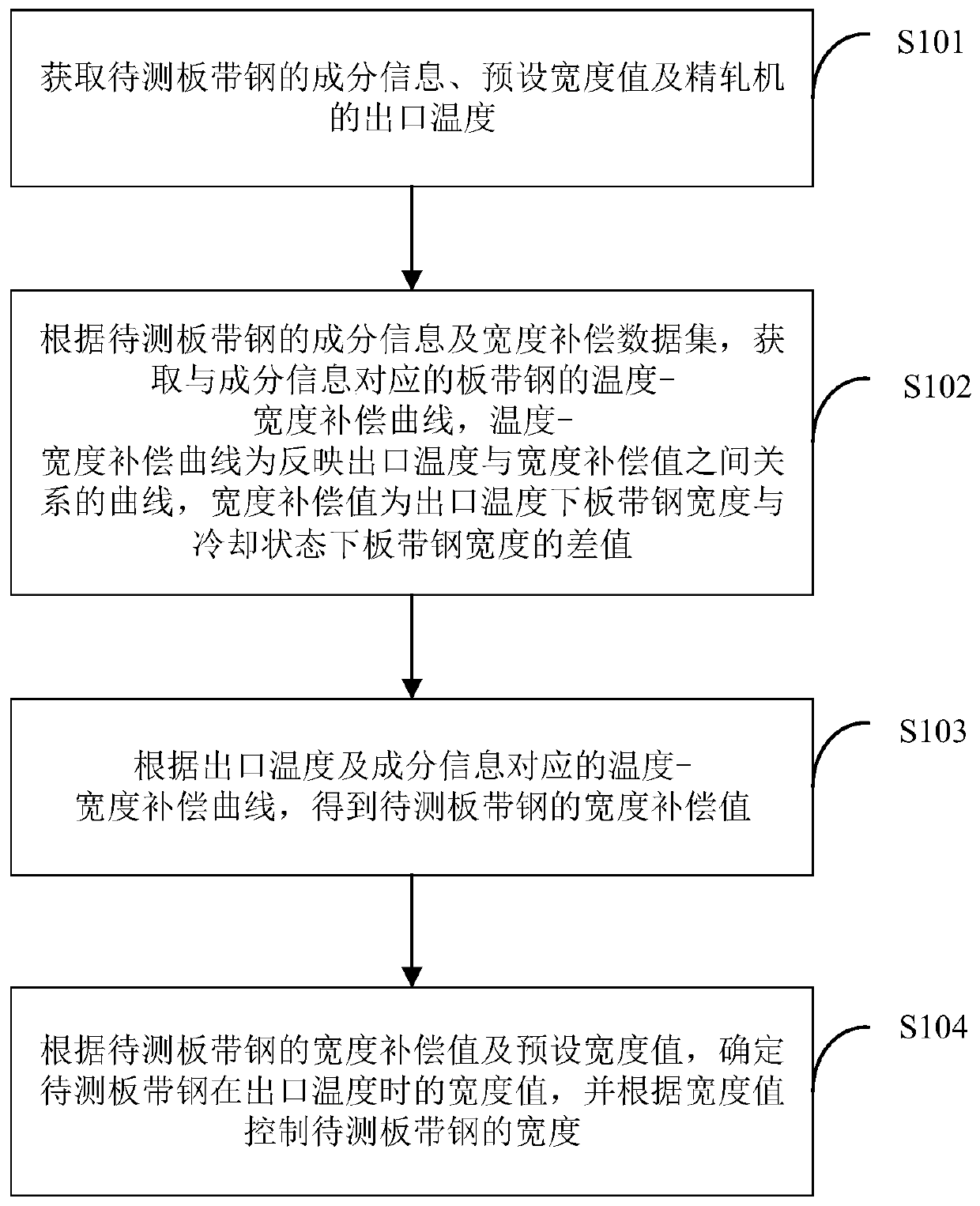

[0028] figure 1 It shows the implementation process of a strip steel width control method provided by an embodiment of the present invention, and the process is described in detail as follows:

[0029] In S101, the component information of the plate and strip to be tested, the preset width value and the exit temperature of the finishing mill are obtained.

[0030] In this embodiment, the composition information is the chemical element information contained in the strip steel, and the composition information of the strip steel can be presented in the form of a table. Taking the vanadium-containing strip steel as an example, the composition information of the vanadium-containing strip steel can be represented by Table 1 shows:

[0031] Table 1

[0032] chemical element C Si mn P content 0.01-0.30 0.05-0.45 0.05-1.50 0.001-0.050 chemical composition S V Ingredient content 0.001-0.050 0.001-0.500

[0033] In this embodiment, th...

Embodiment 2

[0072] Such as Figure 4 As shown, an embodiment of the present invention provides a strip steel width control device 100 for performing figure 1 The method step in the corresponding embodiment, it comprises:

[0073] An information acquisition module 110, configured to acquire the component information of the plate and strip to be tested, the preset width value and the exit temperature of the finishing mill;

[0074] The curve acquisition module 120 is used to obtain the temperature-width compensation curve of the strip steel corresponding to the composition information according to the composition information of the strip steel to be tested and the width compensation data set, and the temperature-width compensation curve reflects the outlet temperature and the width compensation curve. The curve of the relationship between the values, the width compensation value is the difference between the width of the strip at the exit temperature and the width of the strip at the cooli...

Embodiment 3

[0095] The embodiment of the present invention also provides a terminal device 5, including a memory 51, a processor 50, and a computer program 52 stored in the memory 51 and operable on the processor 50. When the processor 50 executes the computer program 52, it realizes Steps in each embodiment as described in embodiment 1, for example figure 1 Step S101 to step S104 are shown. Alternatively, when the processor 50 executes the computer program 52, it realizes the functions of each module in each device embodiment as described in Embodiment 2, for example Figure 5 The functions of modules 110 to 140 are shown.

[0096] The terminal device 5 may be computing devices such as desktop computers, notebooks, palmtop computers, and cloud servers. The terminal device 5 may include, but not limited to, a processor 50 and a memory 51 . For example, the terminal device 5 may also include an input and output device, a network access device, a bus, and the like.

[0097] The so-calle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com