Welding equipment for construction

A technology for welding equipment and construction, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of large randomness of manual bending, time-consuming and labor-intensive use, and troublesome use, so as to save manpower and uniform bending shape , the effect of improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

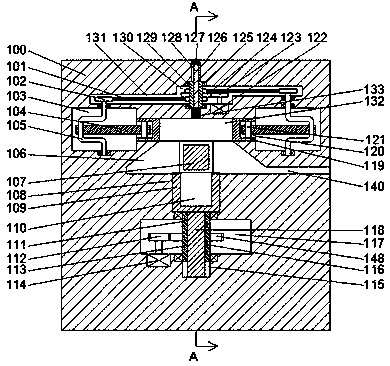

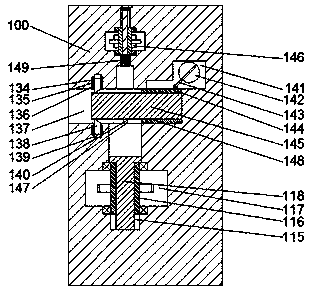

[0015] Such as Figure 1-Figure 2As shown, a construction welding device of the present invention includes a fuselage 100 and a first cavity 106 disposed in the fuselage 100, and a first cavity with an upward opening is arranged in the bottom wall of the first cavity 106. Sliding cavity 108, the first sliding block 109 that can slide up and down in the first sliding cavity 108 is provided with a second cavity 110 with an opening upwards and front and back through the first sliding block 109, the first The bottom wall of the sliding cavity 108 is provided with a third cavity 117, and the bottom wall of the first sliding cavity 108 is communicated with a fourth cavity 115 penetrating through the third cavity 117. The fourth cavity 115 A first shaft sleeve 113 is rotatably provided, and a first gear 148 is fixedly mounted on the outer surface of the first shaft sleeve 113. A first threaded hole 116 penetrating up and down is arranged inside the first shaft sleeve 113. A threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com