Multilayer film for resealable packaging

A multi-layer film and thin-layer technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of unsuitable resealable packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

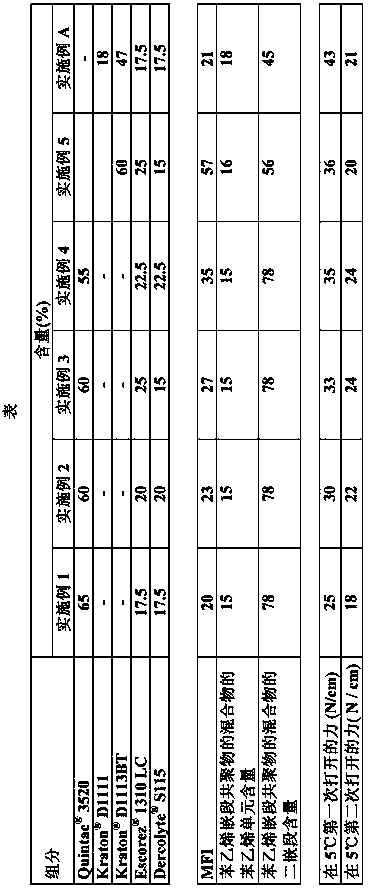

[0082] In the adhesive composition indicated in the table below, 0.5% of irganox® 1010 was added to it and prepared as a viscous liquid at 160°C by simply mixing the ingredients (using a twin-screw extruder) at that temperature.

[0083] MFI is shown in the table.

[0084] Measure the first opening force by peeling at 5°C:

[0085] A multilayer film including an adhesive layer composed of the composition is prepared in the following manner.

[0086] Approximately 8 g of the adhesive composition was placed on a square PET sheet with a side length of 15 cm and a thickness of 50 microns. Then apply a second PET sheet that is the same as the first PET sheet, and apply 100kg / cm on the assembly using a hydraulic press at a temperature of 120°C 2 Pressure for 2 minutes. The thickness of the adhesive layer in the multilayer film (monitored using a caliper) is approximately 250 microns.

[0087] A rectangular sample of 1 cm×10 cm was cut from the multilayer film thus obtained, and the sample ...

Embodiment 2-5

[0095] Example 1 was repeated using the contents shown in the table (for the ingredients of the composition).

[0096] The obtained first and second opening forces are also shown in the table.

Embodiment A

[0097] Example A (comparative):

[0098] Example 1 was repeated using a mixture of Kraton® D1111 and Kraton® D1113BT in the ratio indicated, so that the composition exemplified by application WO02 / 064694 was obtained.

[0099] It was observed that the first opening force of Examples 1 to 5 was reduced relative to Example A, indicating that the resealable package is easier to open. In addition, Examples 2 to 4 show a significant increase in the force of the second opening compared to Example A, which reflects that the quality of the resealing of the package (once opened) is improved.

[0100]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com