A device and method for increasing the service life of single-spindle detection equipment

A detection equipment and a single-spindle technology, which is applied in the direction of textiles and papermaking, can solve the problems of shortened service life of light-emitting elements, high energy consumption, and large current, so as to reduce production equipment and labor costs, improve workers' work efficiency, eliminate The effect of missing and missing spindles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

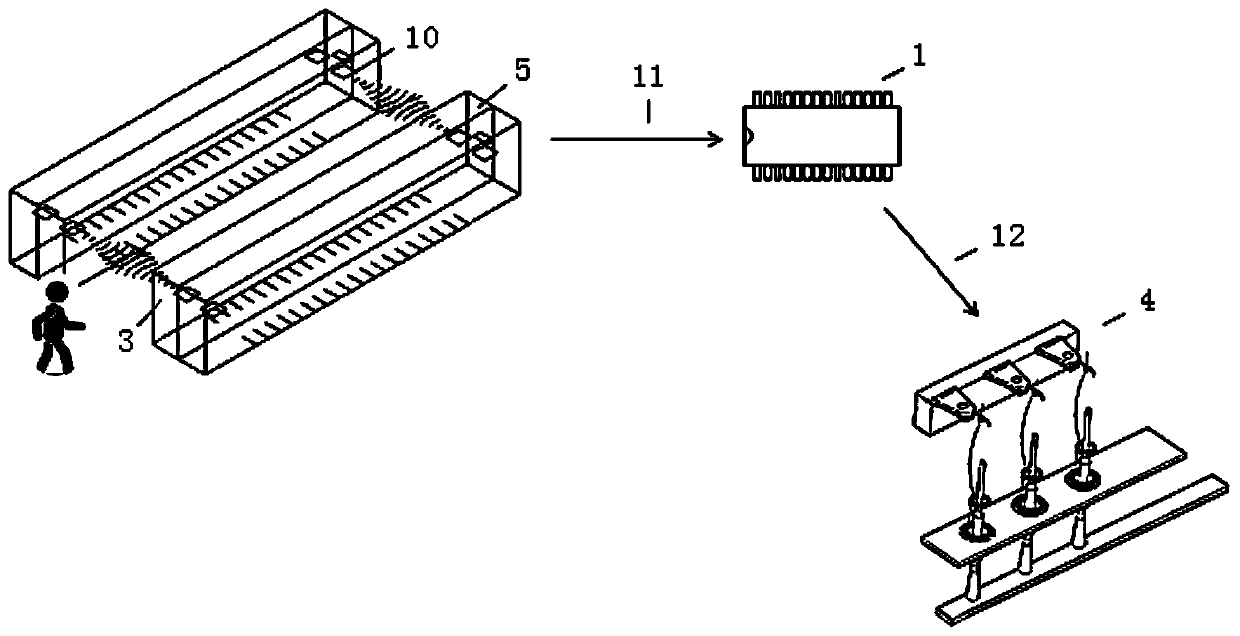

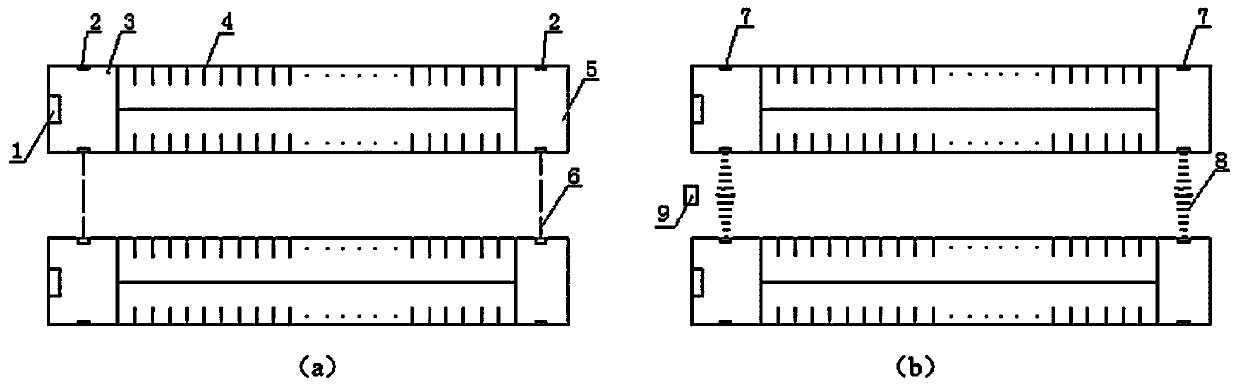

[0045] This embodiment provides a device and method for increasing the service life of single ingot detection equipment, the device comprising:

[0046] Human sensor module;

[0047] The human body sensing module is used to acquire signals generated by workers passing through the spinning frame, so that the single-spindle detection equipment can determine the running state according to the signal obtained by the human body sensing module, and the running state includes working state and dormant state.

[0048] Obtain the signal generated when the worker passes the spinning frame;

[0049] The operating state of the single-spindle detection equipment is determined according to the signal generated when the worker passes the spinning frame, and the operating state includes a working state and a dormant state.

[0050] The present invention senses the signal generated by workers passing through the spinning frame through the human body induction module, and judges according to t...

Embodiment 2

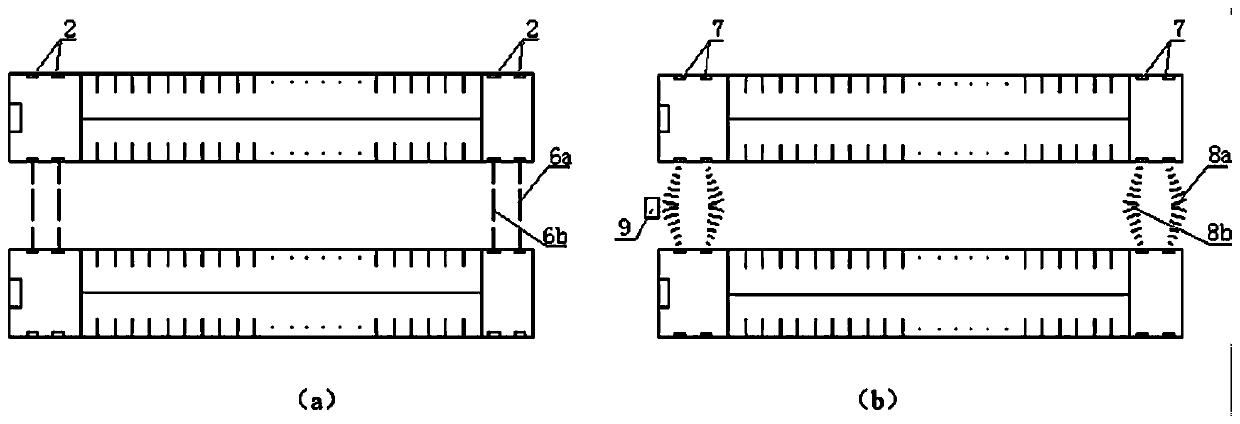

[0052] This embodiment provides a device and method for increasing the service life of single ingot detection equipment, the device comprising:

[0053] Human body sensing module, control module and control switch;

[0054] The human body sensing module is used to acquire signals generated by workers passing through the spinning frame, so that the single-spindle detection equipment can determine the running state according to the signal obtained by the human body sensing module, and the running state includes working state and dormant state.

[0055] The control module is used to send a control signal to the single ingot detection device according to the signal obtained by the human body induction module;

[0056] After the human body sensing module acquires the signal generated by the worker passing through the spinning frame, the signal is sent to the control module, so that the control module sends a control signal to the single-spindle detection device according to the signa...

Embodiment 3

[0080] This embodiment provides a device and method for increasing the service life of single ingot detection equipment, the device comprising:

[0081] Human body sensing module, counting module and control switch;

[0082] The human body sensing module is used to acquire signals generated by workers passing through the spinning frame, so that the single-spindle detection equipment can determine the running state according to the signal obtained by the human body sensing module, and the running state includes working state and dormant state.

[0083] The control module is used to send a control signal to the single ingot detection device according to the signal obtained by the human body induction module;

[0084] After the human body sensing module acquires the signal generated by the worker passing through the spinning frame, the signal is sent to the control module, so that the control module sends a control signal to the single-spindle detection device according to the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com