Bearing platform device for pile foundation model test with adjustable rigidity and test method thereof

A model test and pile foundation technology, applied in the test of foundation structure, foundation structure engineering, construction, etc., can solve the problems of inconvenient conversion of rigid connection and hinge connection, non-removable reuse, poor working conditions, etc., and achieve easy maintenance and repair, Simple structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

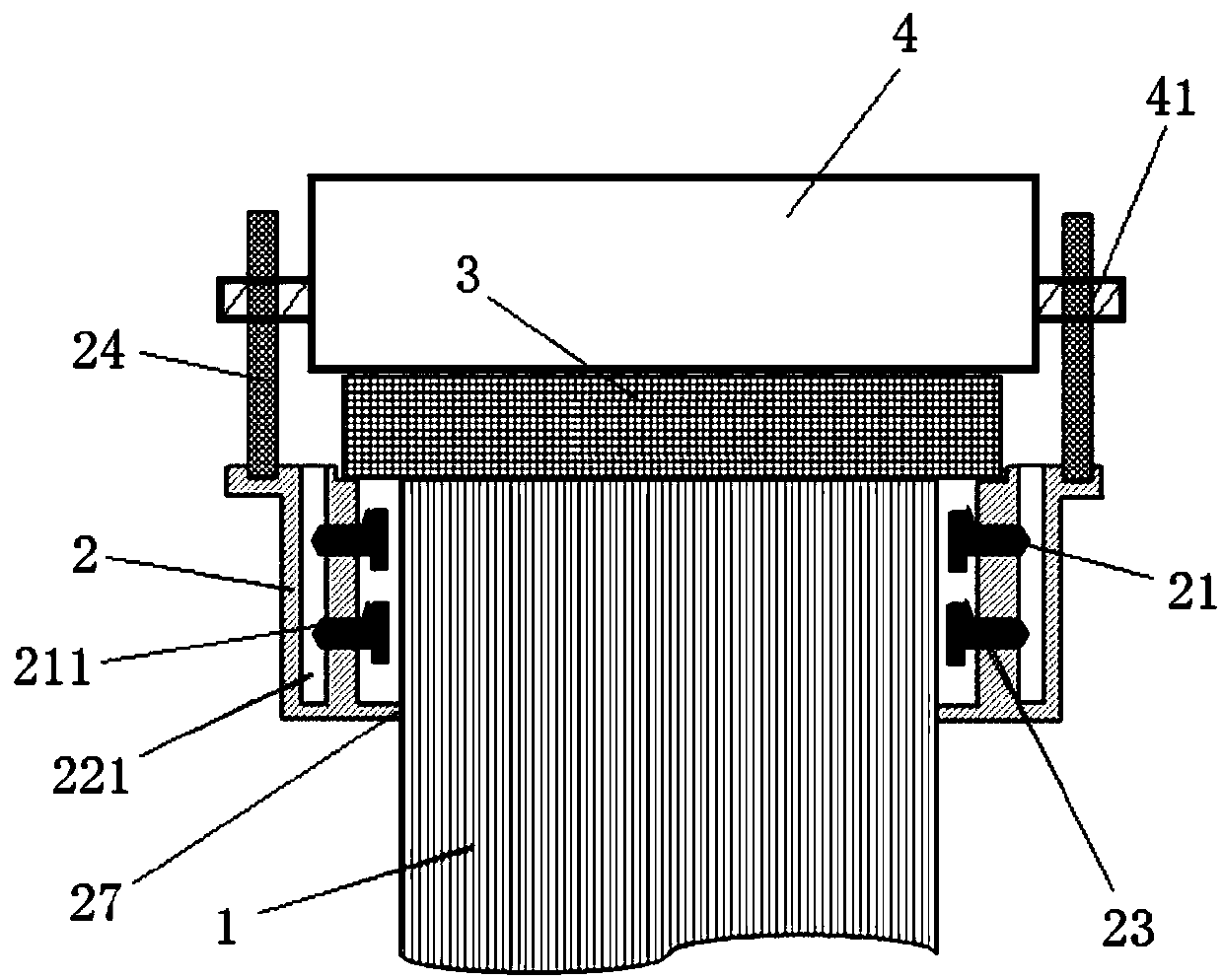

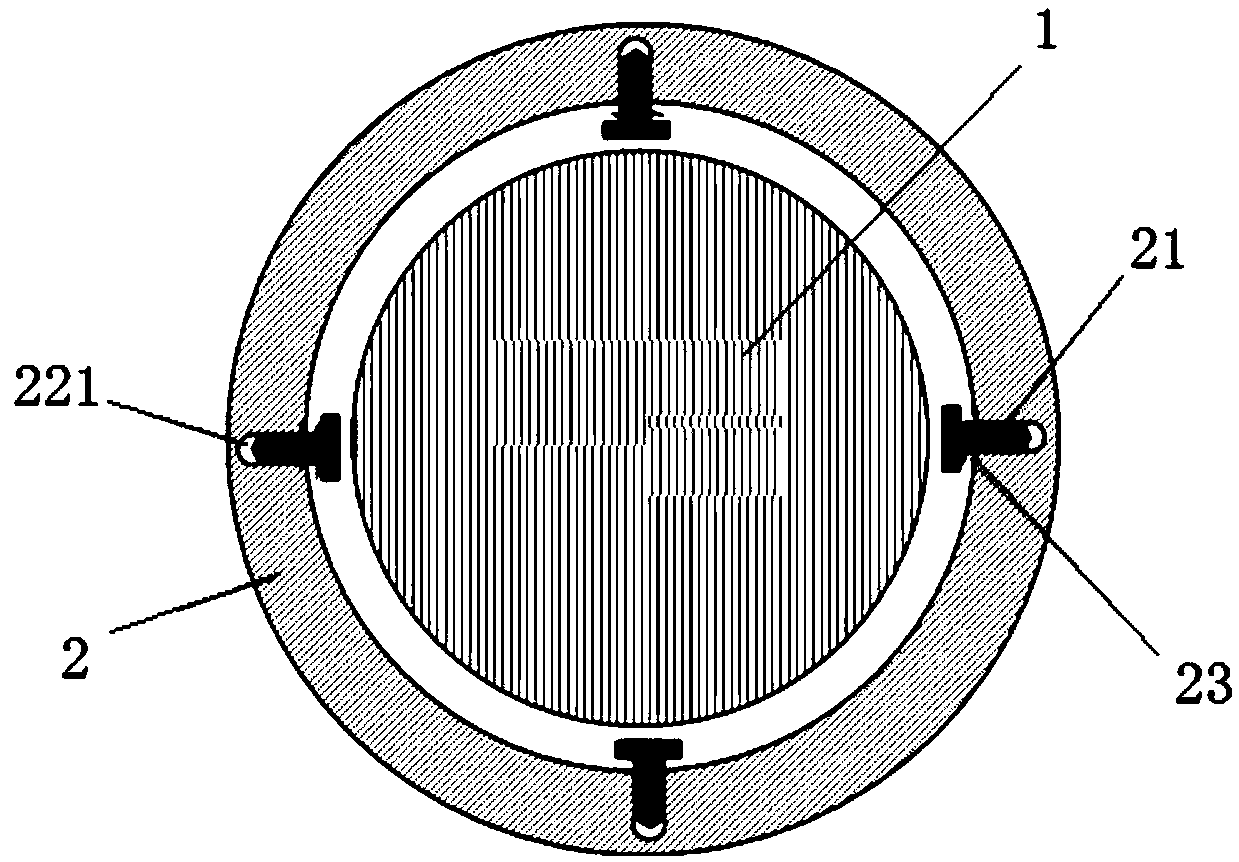

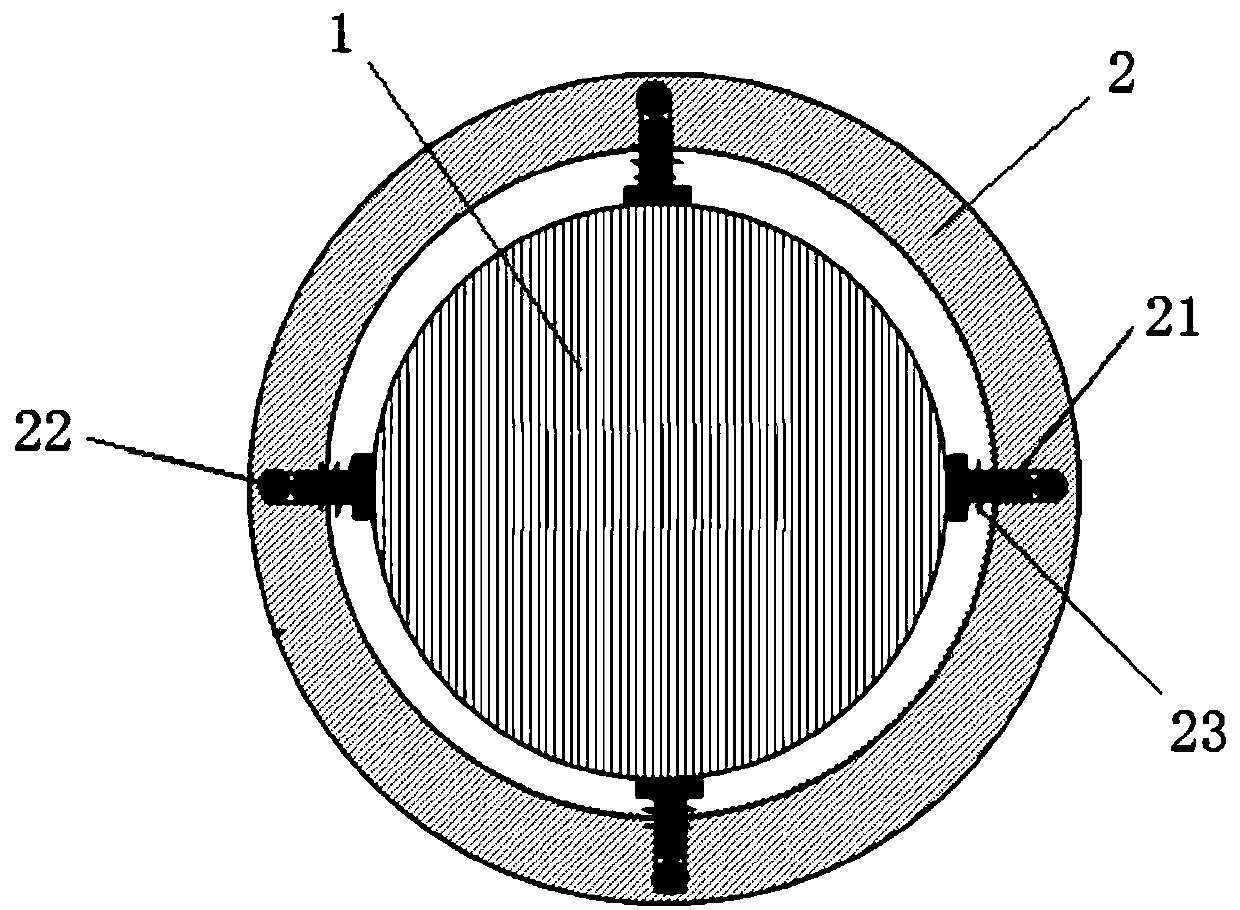

[0042] Such as Figure 1-4As shown, this embodiment provides a pile foundation model test cap device, including a cap frame 2 sleeved on the outside of the model pile 1, above the model pile 1 is provided with a device for applying vertical pressure to the The upper structure 4 of the model pile 1, a pressure sensor 3 and a backing plate (not shown in the figure) are sequentially arranged between the model pile 1 and the upper structure 4, and preferably, the pressure sensor 3 can be A pressure sensor commonly used in the market is selected, and the platform frame 2 is connected to the upper structure 4 through a connecting piece.

[0043] The inner side of the platform frame 2 is sequentially provided with a first concave surface 25, a second concave surface 26 with gradually smaller areas, and a through hole 27 connected to the model pile 1 in a gap from top to bottom. The second concave surface 26 The opening height is greater than the opening height of the first concave s...

Embodiment 2

[0051] In order to facilitate the understanding of this technical solution, based on the above cap device, here is a pile foundation model test method with adjustable constraint stiffness, such as Figure 5 shown, including the following steps:

[0052] Step 1: Embedding the model pile 1 into the soil of the model test until the height of the pile top meets the test requirements.

[0053] Step 2. According to the shape and size of the model pile 1, adjust the length of the sliding rod 213 of the ejector part 21 and the radian and length of the arc-shaped smooth contact surface 28, and select a pressure sensor 3 with a suitable diameter.

[0054] Step 3, select the shape and size of the first concave surface 25 according to the shape of the pressure sensor 3, and select the thickness of the backing plate according to the height and diameter of the pressure sensor 3;

[0055] Step 4: Connect the tension spring 23 between the top pressure block 212 of the ejection part 21 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com