Water drainage system of loess gully bridge site

A drainage system and gully technology, applied in waterway systems, sewer systems, water supply devices, etc., can solve the problems of double-wall corrugated pipes that cannot meet the drainage requirements, difficult treatment of pier pile foundations, and loss of drainage functions, etc. The cost of maintenance and maintenance, the avoidance of erosion and water damage, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

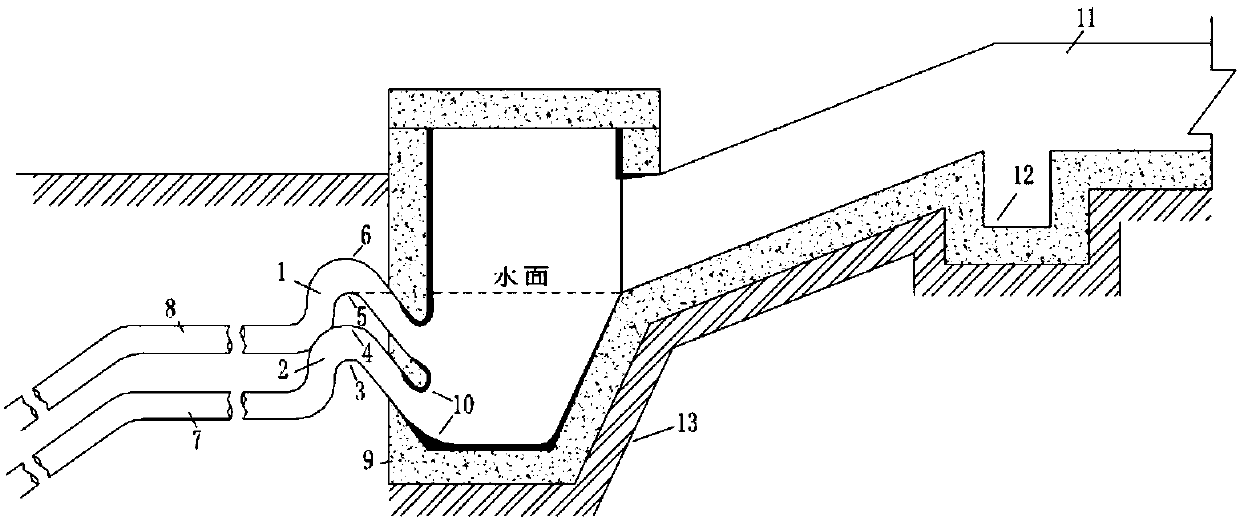

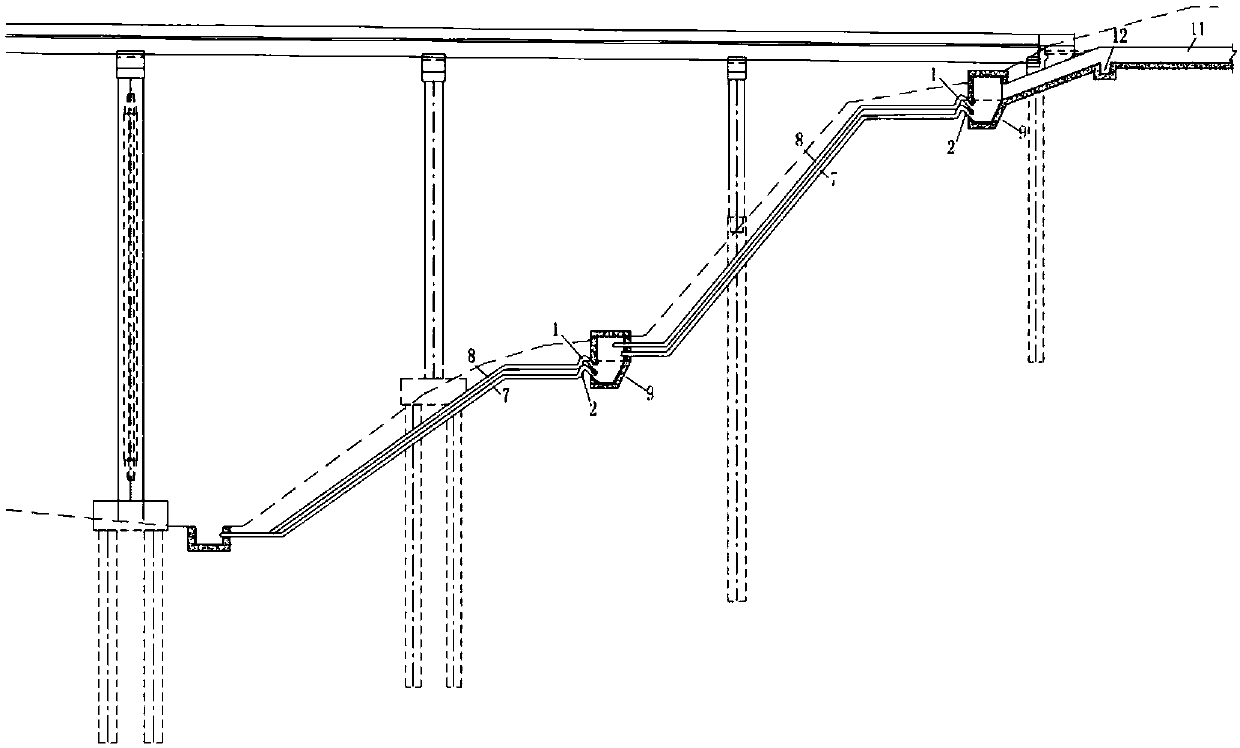

[0021] A loess gully bridge site drainage system, the drainage system includes a top bend 1, a bottom bend 2, a lower drain 7, an upper drain 8, a sump 9 and a side ditch 11; The height of the ditch is laid out; the bottom of the sump 9 is narrow and the top is wide; one end of the top bend 1 and bottom bend 2 is sealed and fixed at the bottom of the sump 9 to reserve drainage holes; the top bend 1 and bottom bend 2 The other end is horizontally connected with the upper drainage pipe 8 and the lower drainage pipe 7 respectively; the water outlets of the upper drainage pipe 8 and the lower drainage pipe 7 are located at the sump 9 at the downhill; the water inlets of the sump 9 and the side ditch 11 are cement Concrete structure; the junction of the top bend 1, bottom bend 2 and the reserved hole of the sump 9 and the inside of the sump 9 should be sealed and waterproofed; the top bend 1, bottom bend 2, upper drain 8, The lower drainage pipe 7 adopts a PVC drainage pipe with a ...

Embodiment 2

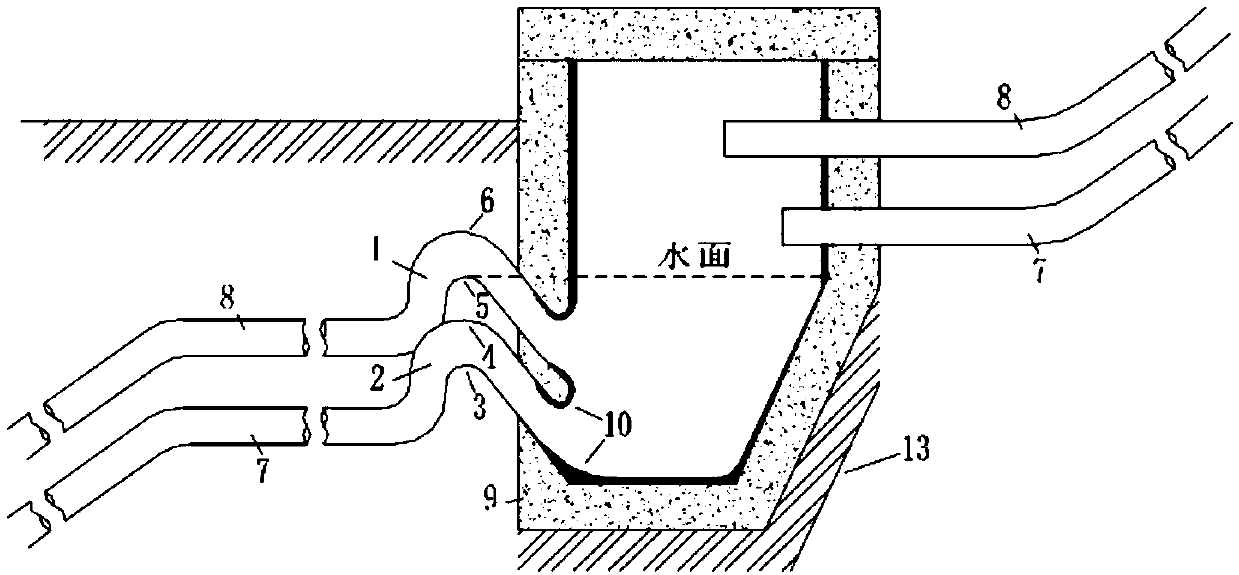

[0023] A loess gully bridge site drainage system, the drainage system includes a top bend 1, a bottom bend 2, a lower drain 7, an upper drain 8, a sump 9 and a side ditch 11; The height of the ditch is laid out; the bottom of the sump 9 is narrow and the top is wide; one end of the top bend 1 and bottom bend 2 is sealed and fixed at the bottom of the sump 9 to reserve drainage holes; the top bend 1 and bottom bend 2 The other end is horizontally connected with the upper drainage pipe 8 and the lower drainage pipe 7 respectively; the water outlets of the upper drainage pipe 8 and the lower drainage pipe 7 are located at the sump 9 at the downhill; the water inlets of the sump 9 and the side ditch 11 are cement Concrete structure; the junction of the top bend 1, bottom bend 2 and the reserved hole of the sump 9 and the inside of the sump 9 should be sealed and waterproofed; the top bend 1, bottom bend 2, upper drain 8, The lower drainage pipe 7 adopts a PVC drainage pipe with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com