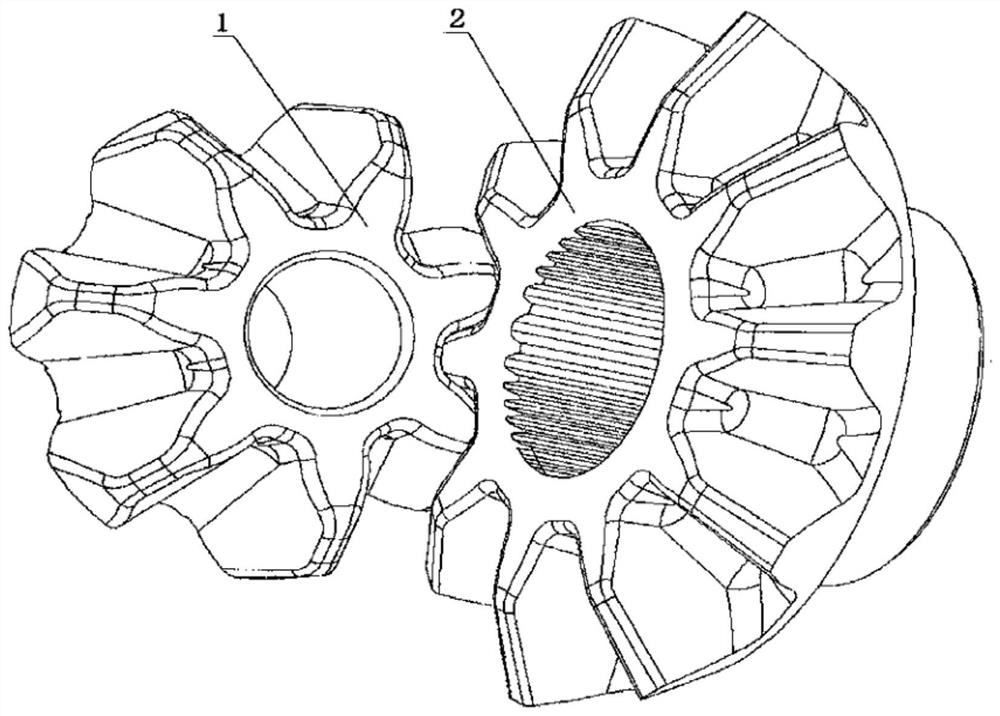

A Spherical Involute Straight Bevel Gear Pair and Its Tooth Profile Modification Method

A technology of spherical involute and straight-toothed bevel gears, which is applied in the direction of belts/chains/gears, components with teeth, hoisting devices, etc., and can solve insufficient shape modification, modeling method errors, and spherical involute transmission Insufficient understanding of characteristics and other issues, to achieve the effect of improving meshing quality and service life, reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

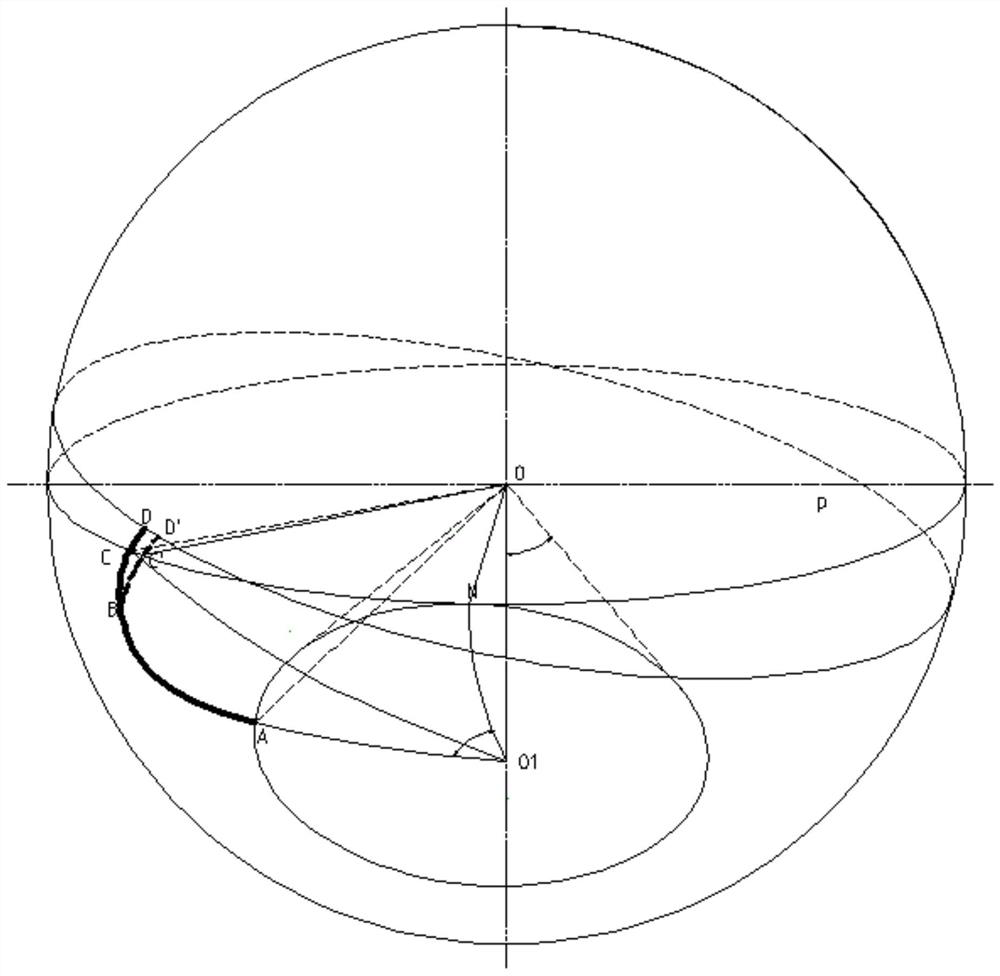

[0064] Such as figure 2 Shown: Section AD is the theoretical spherical involute, plane P is the occurrence surface of the spherical involute, cone OO1A is the base cone of the spherical involute, O is the apex, B is the starting point of the modification, and the tooth profile after modification Divided into two sections, the AB section is the theoretical spherical involute, and the BD' section is the spherical modification curve;

[0065] Establish a global Cartesian coordinate system S, where the origin of the coordinates is the vertex O of the base cone, define the direction of the vector OO1 as the z-axis, define the direction of the vector O1A as the x-axis, and define the directions of the z-axis and the x-axis as y according to the right-hand rule Axis, spherical involute derivation is common knowledge, this application does not make specific derivation, and directly gives the conclusion:

[0066] The spherical involute of segment AB, its equation is:

[0067]

[...

Embodiment 2

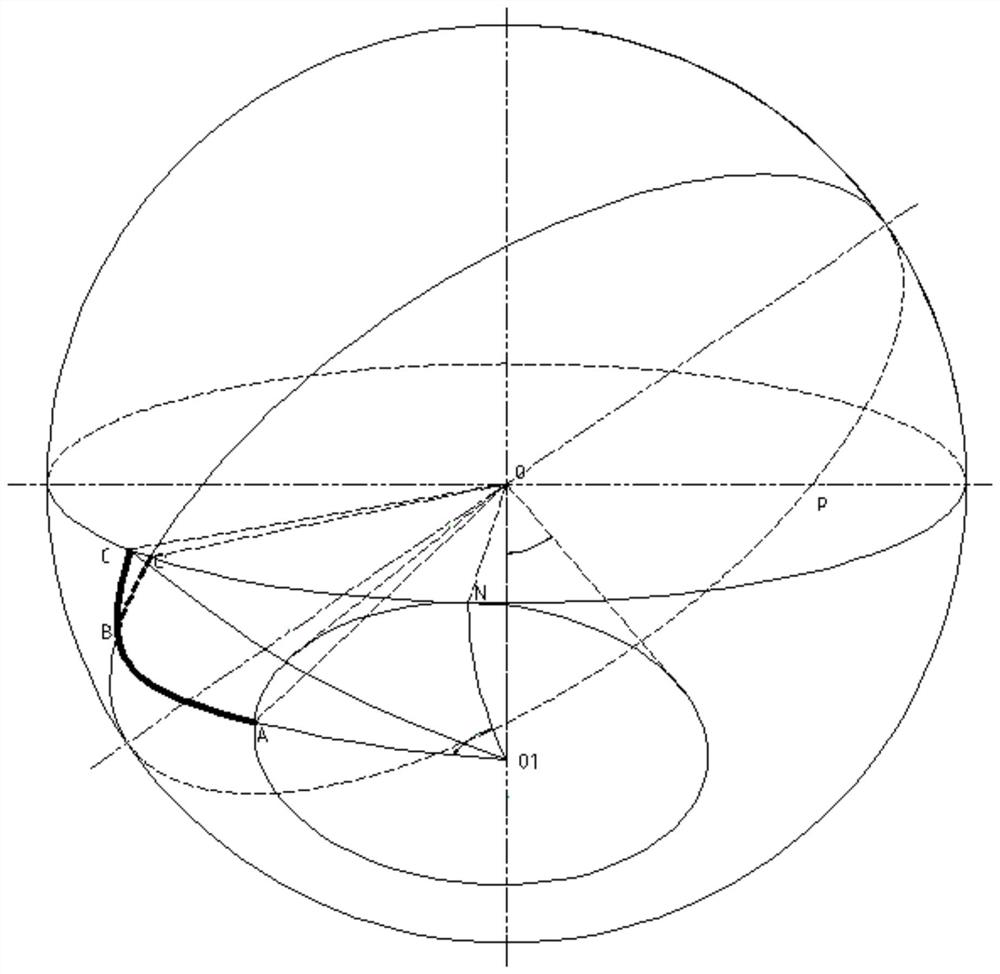

[0107] Such as image 3 As shown, considering that the small end modulus and tooth height of the bevel gear are small, the BC arc length of the part of the spherical involute that needs to be modified here usually does not exceed 0.1, as shown in image 3 The calculation of the method can completely achieve the same technical effect, and can simplify the calculation and improve the work efficiency. In order to simplify the modeling, only the theoretical spherical involute tooth apex C is calculated according to the method in the specific embodiment 1. The coordinate point C' after the tooth top modification , the modification curve BC′ is a section of a great circle inferior arc connecting the tooth tip modification point C′ and the modification starting point B on the spherical surface of the sphere where the spherical involute is located; its equation is easy to obtain, and the three-dimensional modeling is also extremely convenient; Fig. Among them, segment AC is the theore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com