Large-scale fiber grating rust sensor

A fiber grating, long-range technology, applied in instruments, measuring devices, optical devices, etc., can solve problems such as it is difficult to directly reflect the corrosion process of steel bars, and achieve the effect of large deformation range, long service life and overcoming small range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

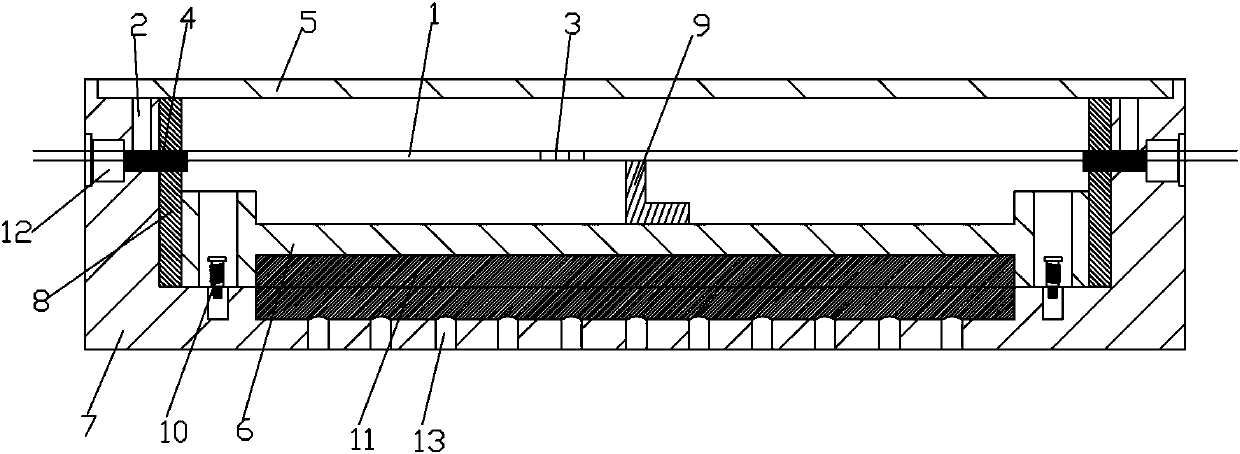

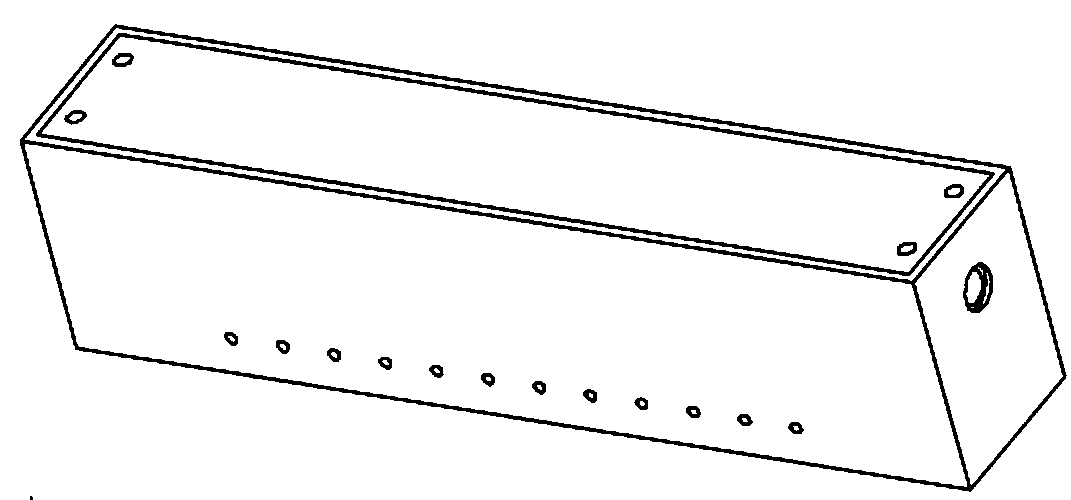

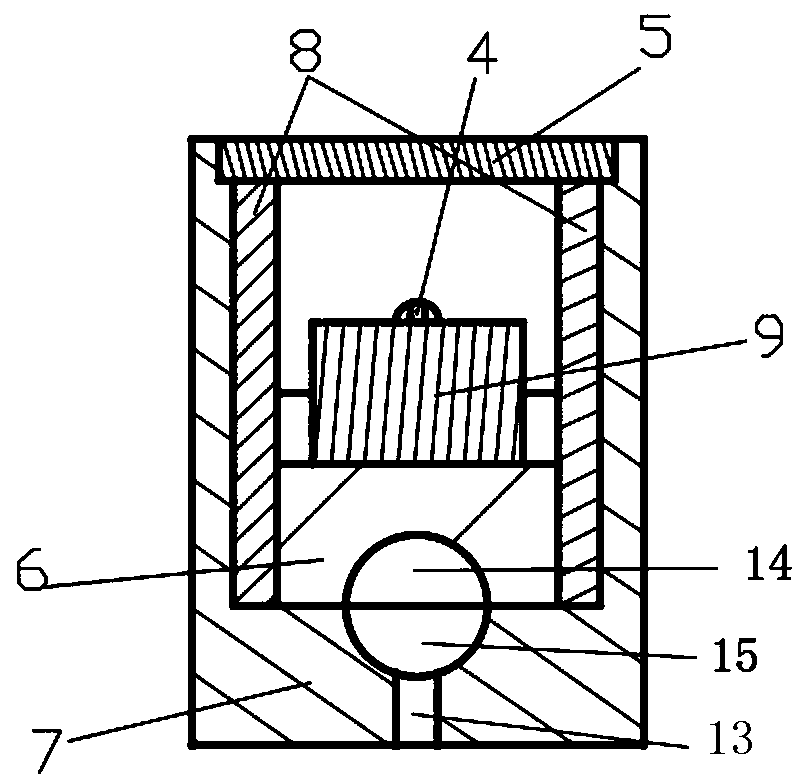

[0031] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0032] see Figure 1-10 .

[0033] The invention discloses a large-range optical fiber grating corrosion sensor, which comprises an upper cavity 6, a lower cavity 7, an L-shaped connector 9, and a grating 3, and the upper cavity 6 is arranged in the cavity of the lower cavity 7 , the two ends of the lower cavity 7 are provided with elastic connecting devices, and the upper cavity 6 and the lower cavity 7 are elastically connected by elastic connecting devices; Lower cavity groove 15, the bottom of the upper cavity 6 is provided with an upper cavity groove 14 with an opening downward, and the upper cavity groove 14 fits with the opening of the lower cavity groove 15 to form a detection Cavity, the bottom and both sides of the lower cavity 7 corresponding to the detection cavity are provided with through holes 13, the detection cavity is provided with threaded ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com