Pipeline crack corrosion monitoring method based on multi-way alternate current potential drop

A technology for alternating current and corrosion detection, which is applied in the direction of measuring devices, material analysis through electromagnetic means, instruments, etc., can solve problems such as limiting the detection range of crack defects, and achieve improved crack depth and solution accuracy, strong anti-interference ability, and excitation current small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

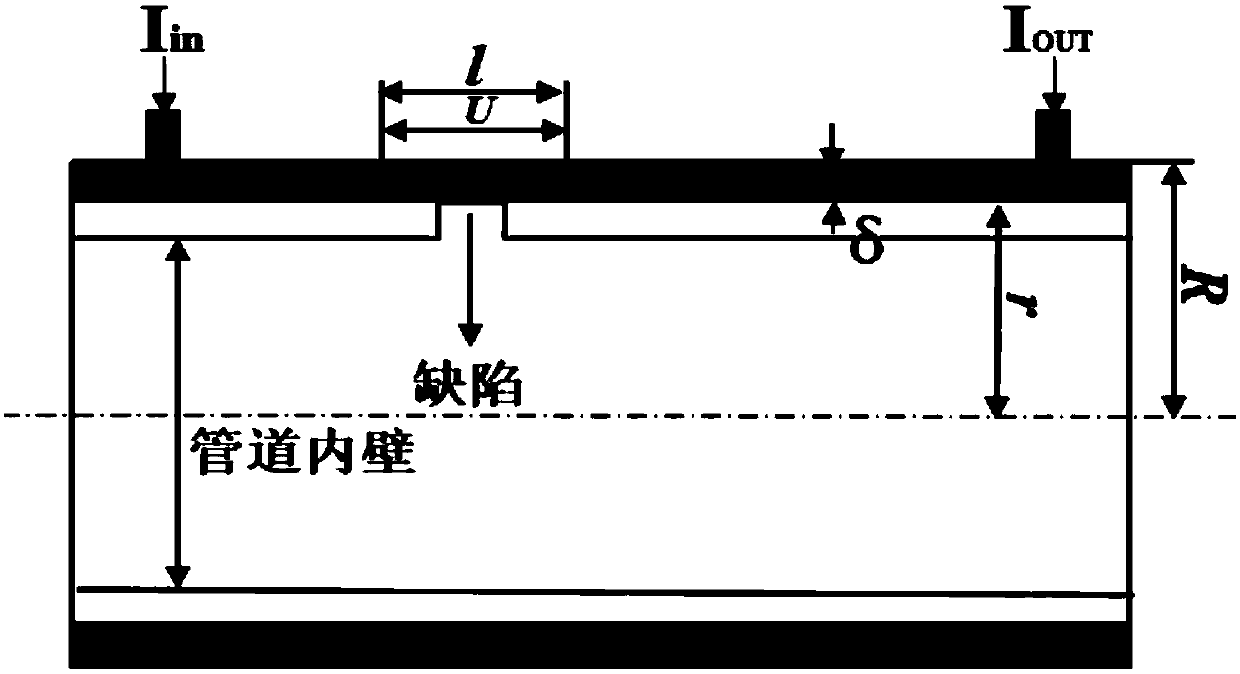

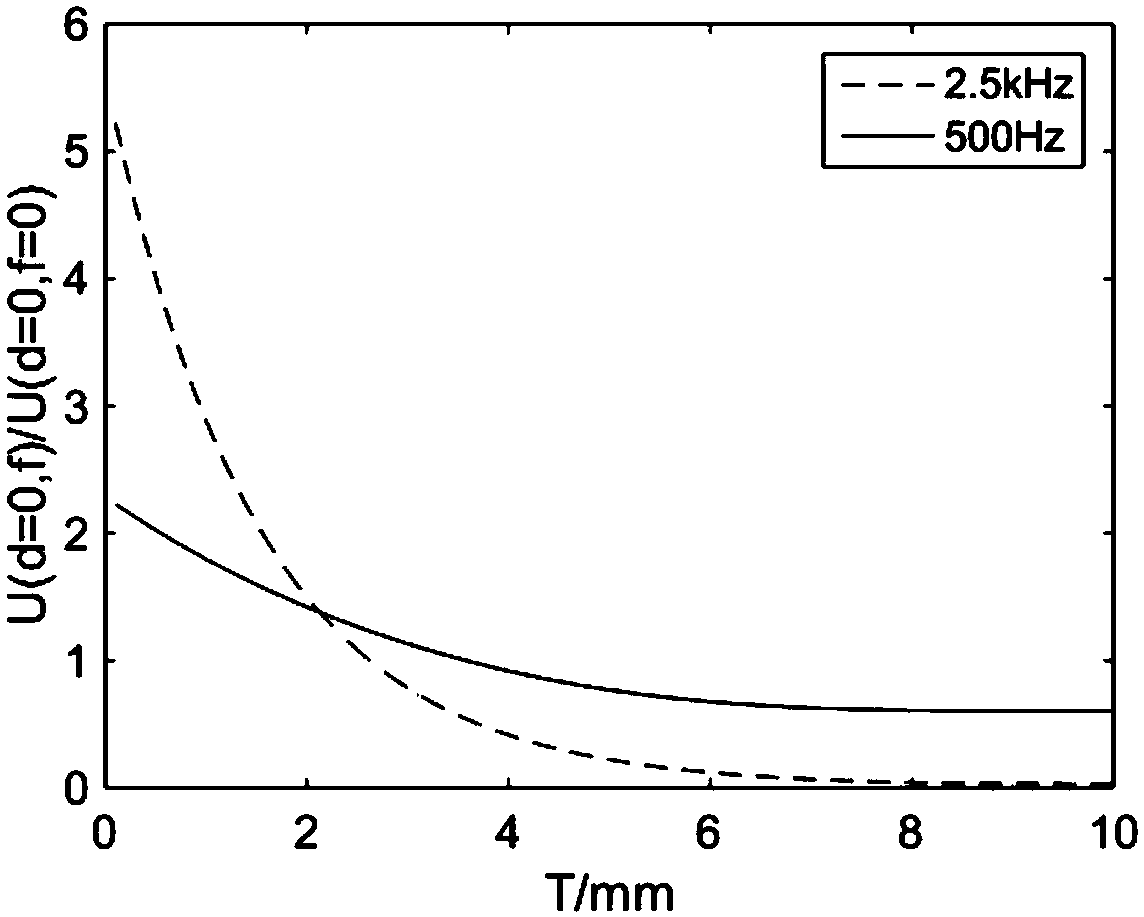

[0081] 3. Embodiment 1. Utilize a plate model to carry out simulation test

[0082] The flat plate model is firstly solved accurately.

[0083] The length of the plate is 220mm, the width is 220mm, the thickness is 10mm, the distance between the measuring probes is 20mm, the amplitude of the injected current is 2A, and the frequency is 100HZ. For details, see Figure 6 shown.

[0084] The defect depth is 2mm, 2.5mm, 3mm, 4mm, 4.5mm, 5mm, 5.5mm, 6mm, and the material parameters are as follows in Table 2:

[0085]

[0086]

[0087] Taking the 0-degree crack defect and the 45-degree crack defect as examples, the measurement results obtained by the two under the above simulation conditions are:

[0088] Take the value of 0 degree defect for depth fitting, the formula is:

[0089]

[0090] The results calculated by formula (7) for 45-degree defects are shown in Table 2 above.

Embodiment 2

[0091] Embodiment 2 utilizes 5 aluminum plates to do the test

[0092] Experimental materials: 5 aluminum plates of 220mm×220mm×10mm, the overall experimental device is as follows Figure 7-8 shown.

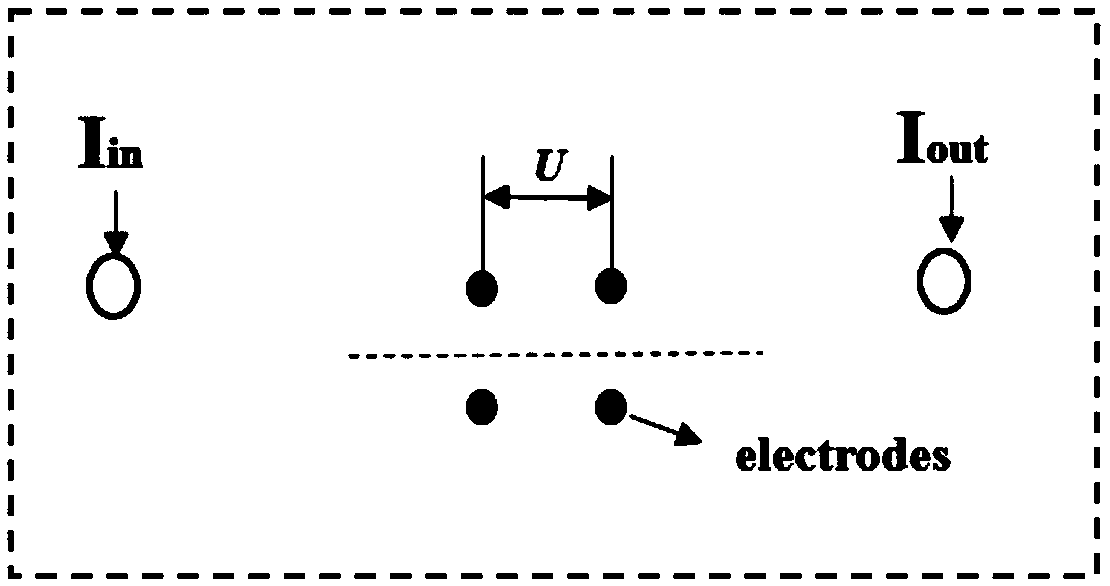

[0093] Before unprocessed defects, followed by I in1 , I in2 , I in3 , I in4 The electrode injects 2A, 100Hz alternating current into the plate, such as Figure 5 , Figure 8 As shown, the probe pairs (P 1 -P 2 ), (P 1 -P 3 ), (P 2 -P 3 ), (P 2 -P 4 ) between the original voltage U 1(d=0) , U 2(d=0) , U 3(d=0) , U 4(d=0) .

[0094] Then, 5 cracks were drawn on the bottom of the 5 plates respectively, among which No. 1-3 plates are 0 degree crack defects, the depths are 2mm, 4mm, 6mm respectively, and the width is 2mm; No. 4-5 plates are 45 degree crack defects , the depth distribution is 3mm, 5mm, such as Figure 9 shown.

[0095] Then, by I in1 , I in2 , I in3 , I in4 electrodes, see e.g. Figure 8 As shown, 2A current and 59-500Hz alternating current c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com