Automatic winding machine and assembling and packaging machine for surface-mounted inductors

An automatic winding machine, chip inductor technology, applied in inductor/transformer/magnet manufacturing, packaging/dipping, circuits, etc., can solve the problems of low degree of automation, low production efficiency, manual loading and unloading, etc., to improve production quality , Improve production efficiency and avoid the effect of winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in conjunction with the following embodiments and accompanying drawings.

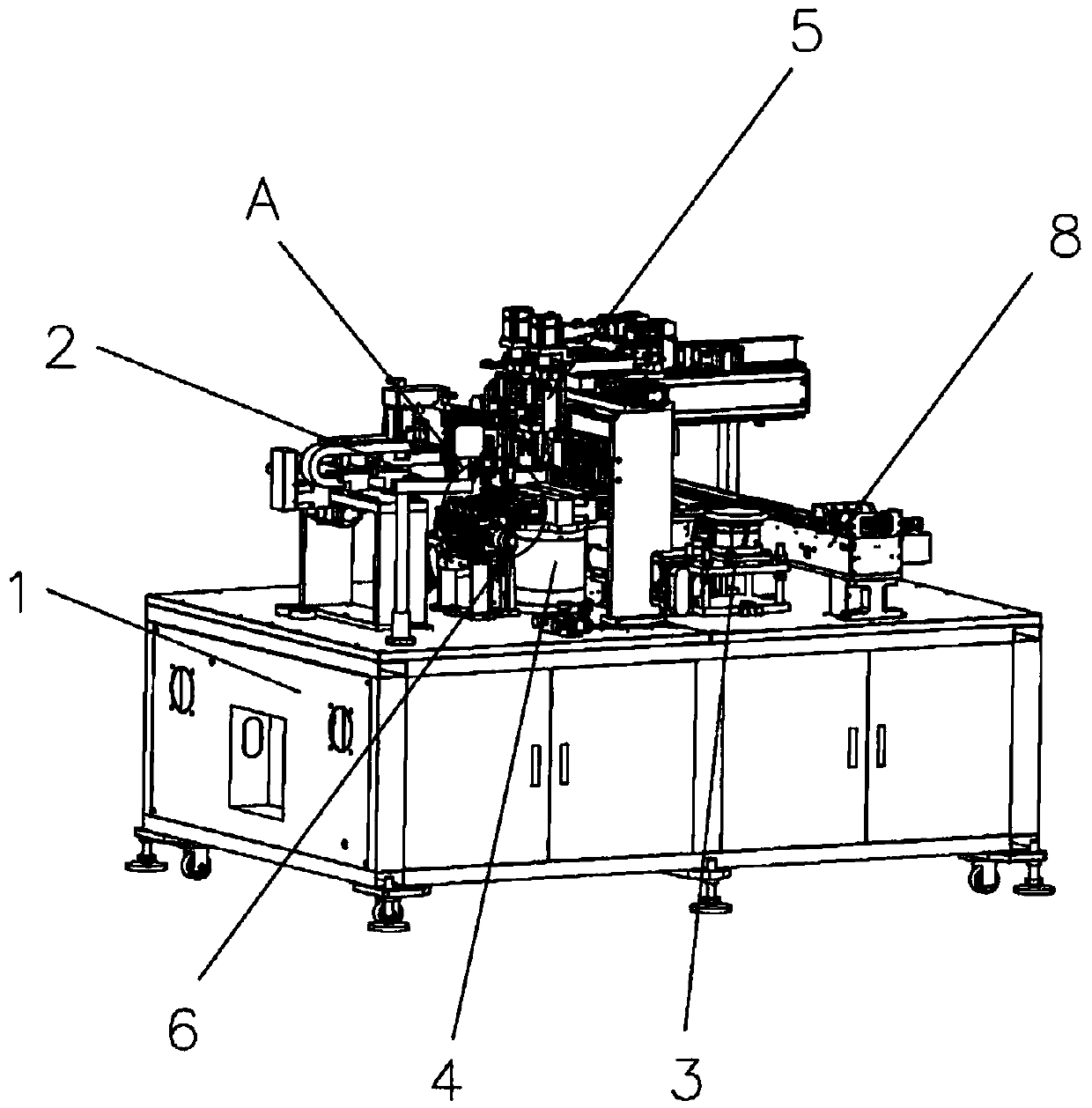

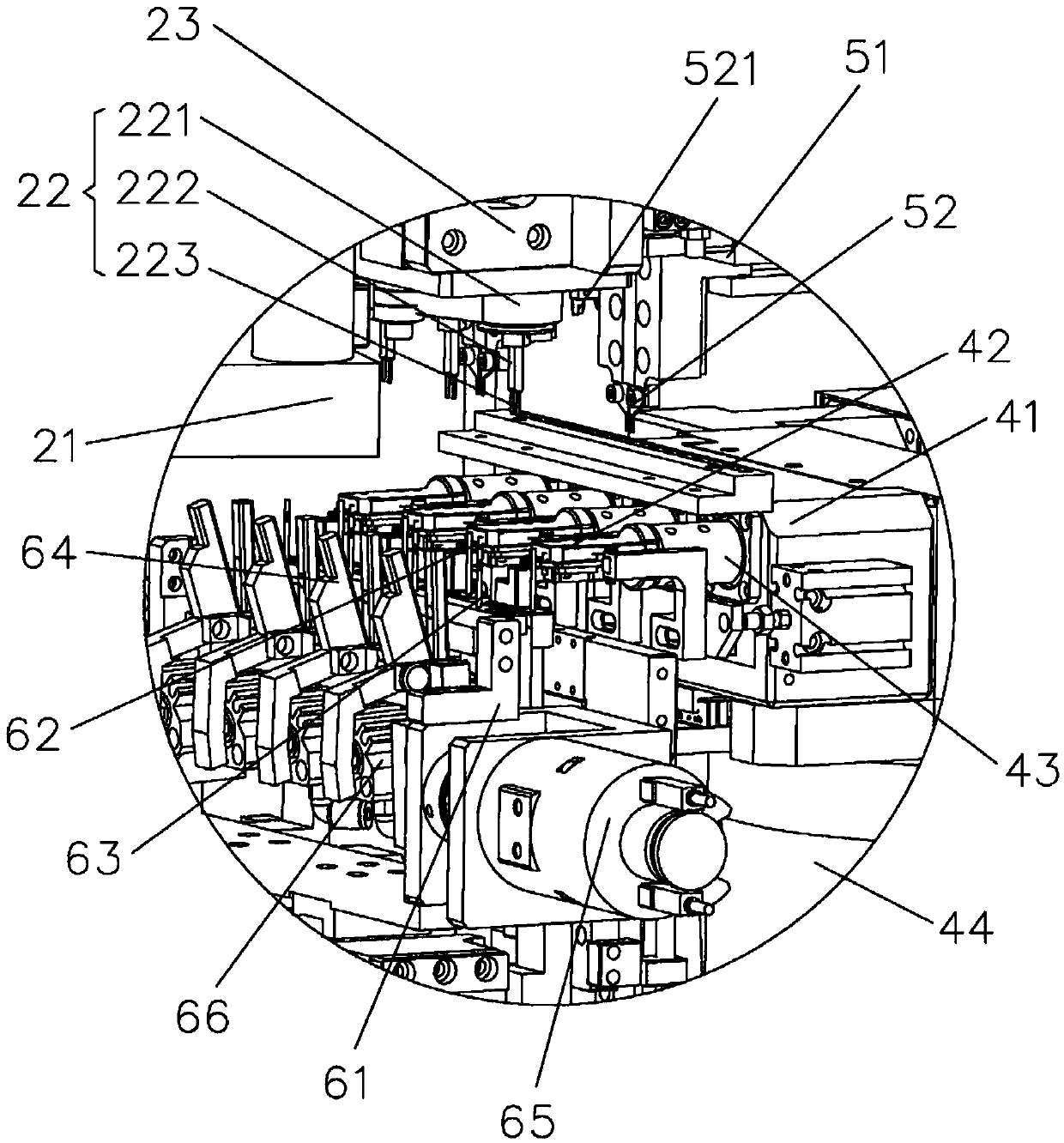

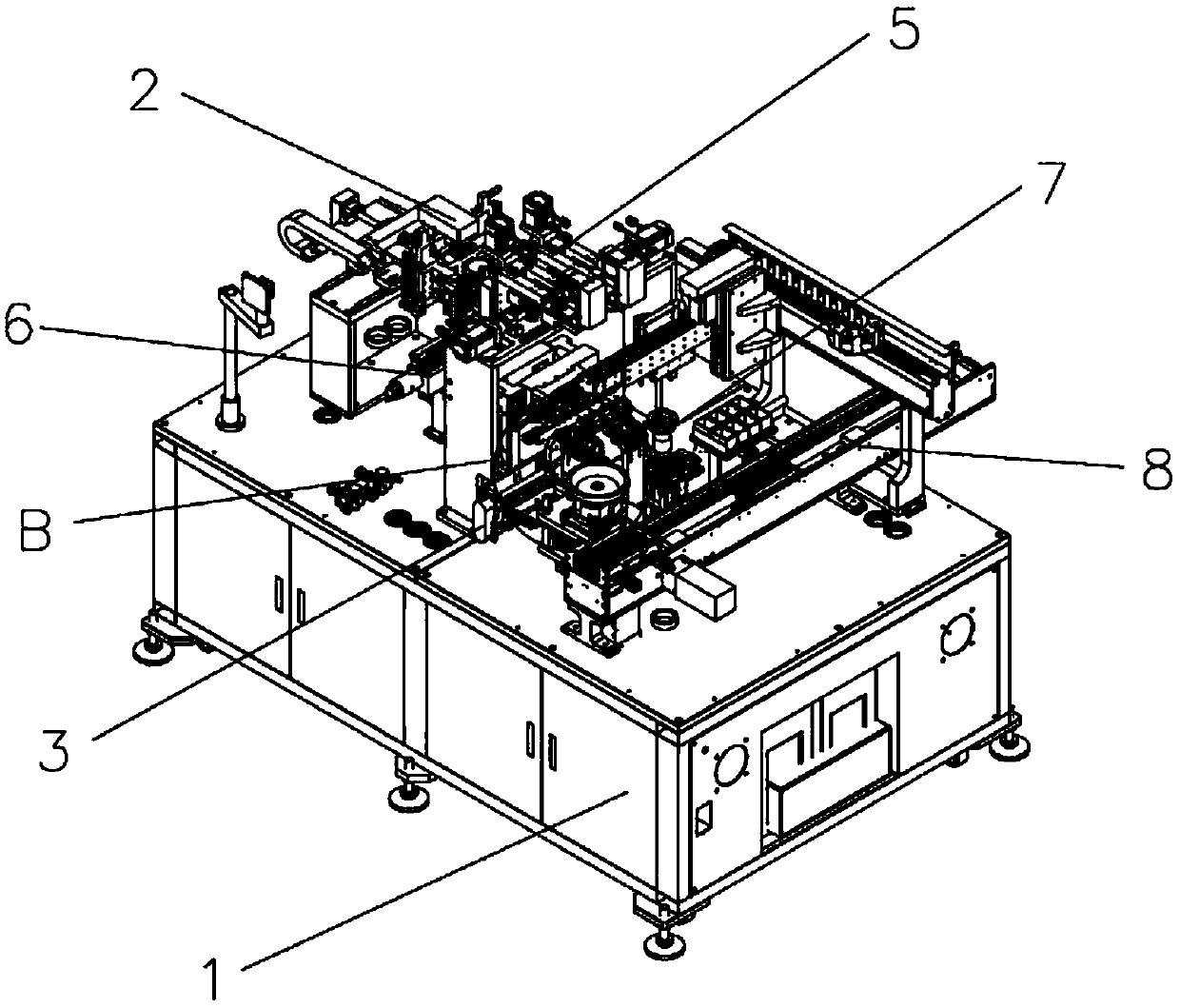

[0036] Such as Figure 1 to Figure 7 As shown, an automatic winding machine for chip inductors of the present invention includes a machine platform 1, a wire feeding mechanism 2 for supplying wire rods, a feeding mechanism 3 for supplying iron cores to an assembly mechanism 4, and a The assembly mechanism 4 for winding the wires around the iron core, the welding mechanism 5 for welding the wires output by the wire delivery mechanism 2 to the iron core carried by the assembly mechanism 4, and the welding mechanism 5 for fixing and removing the wires produced by the wire delivery mechanism 2 The thread clamping mechanism 6 for the remaining thread, the thread feeding mechanism 2, the feeding mechanism 3, the assembly mechanism 4, the welding mechanism 5 and the thread clamping mechanism 6 are all arranged on the machine platform 1.

[0037]During wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com