Industrial production and processing integrated machine

An all-in-one, protective casing technology, applied in the direction of chassis/cabinet/drawer parts, casings with display/control units, electrical components, etc., can solve problems such as poor contact, inability to fix network cables, loss, etc. To achieve the effect of convenient mobile use, convenient operation and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

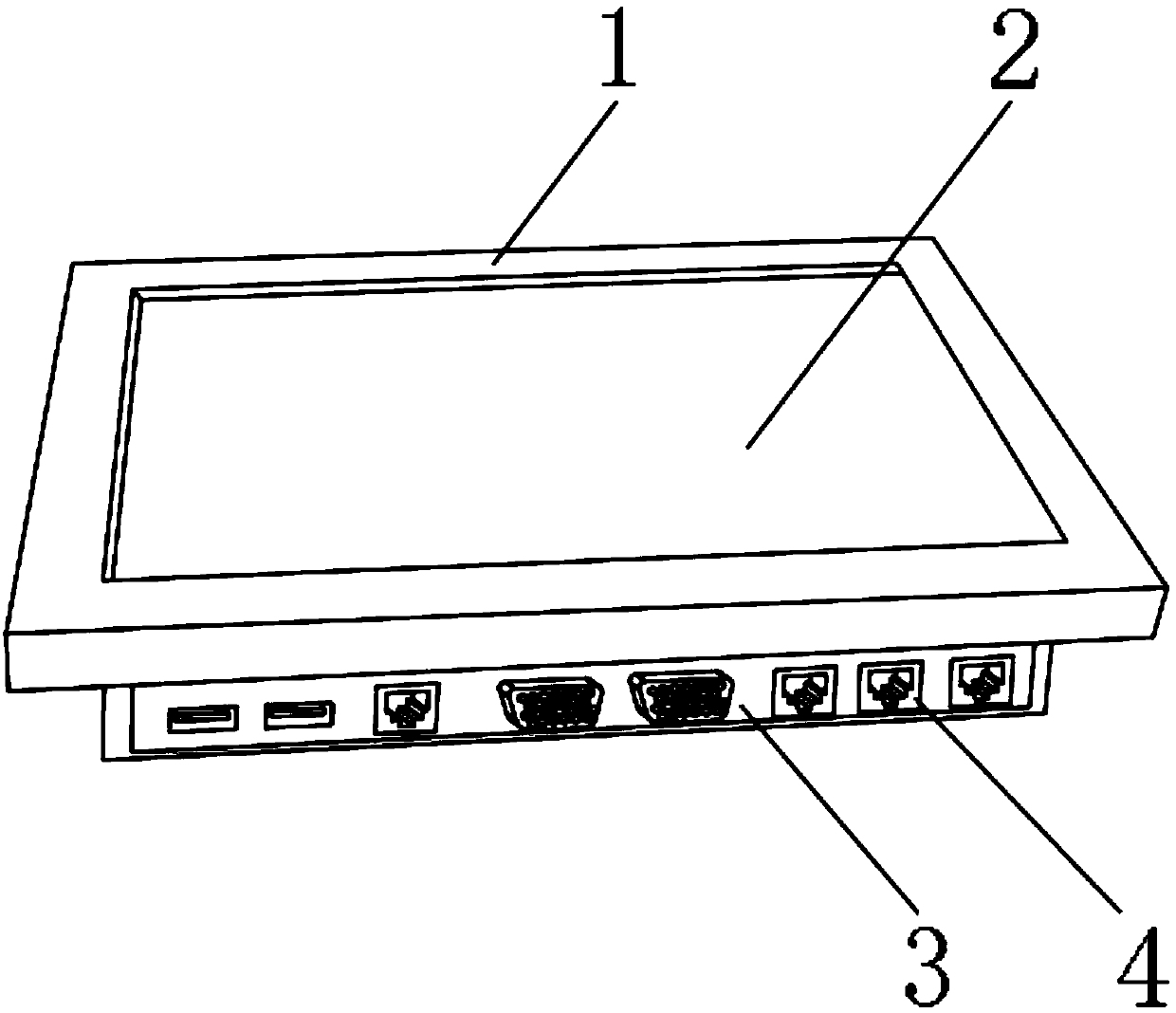

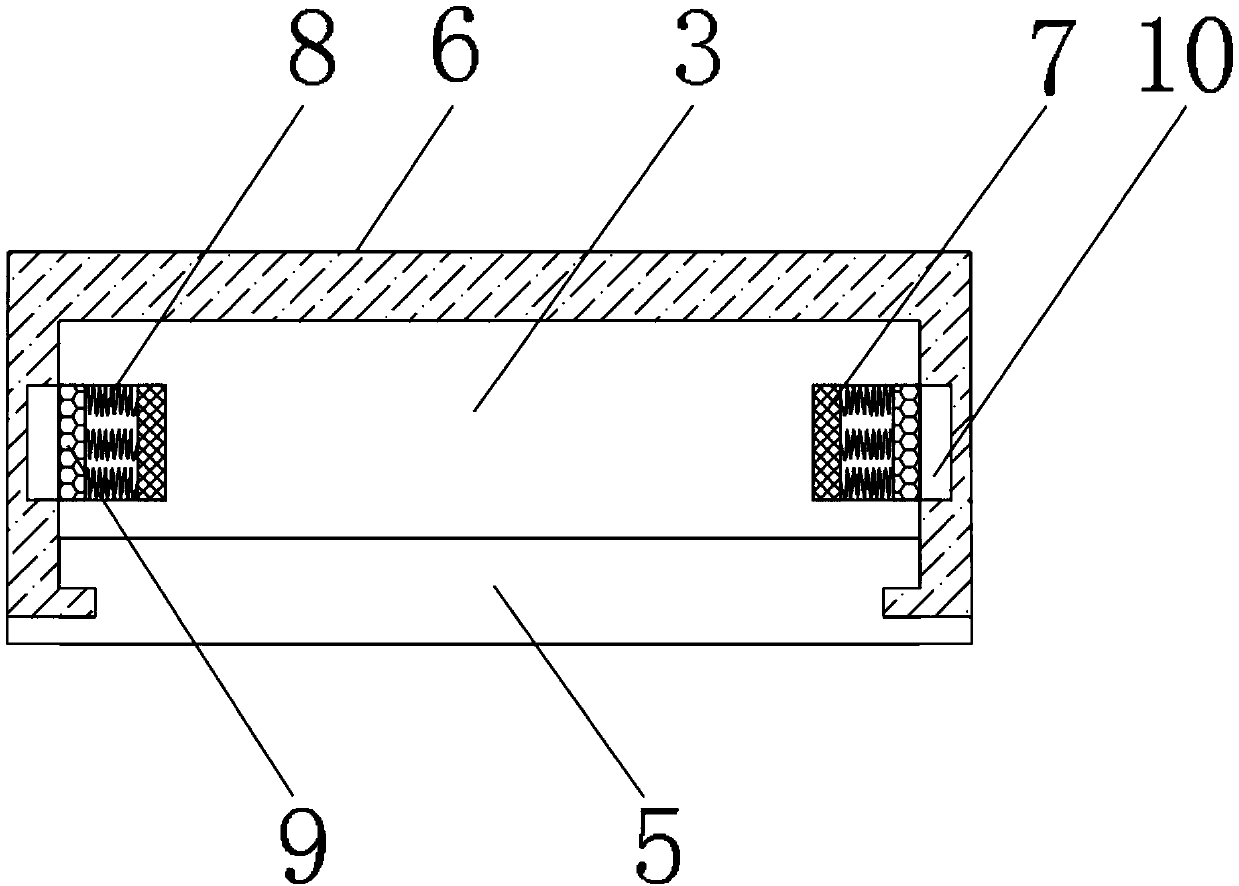

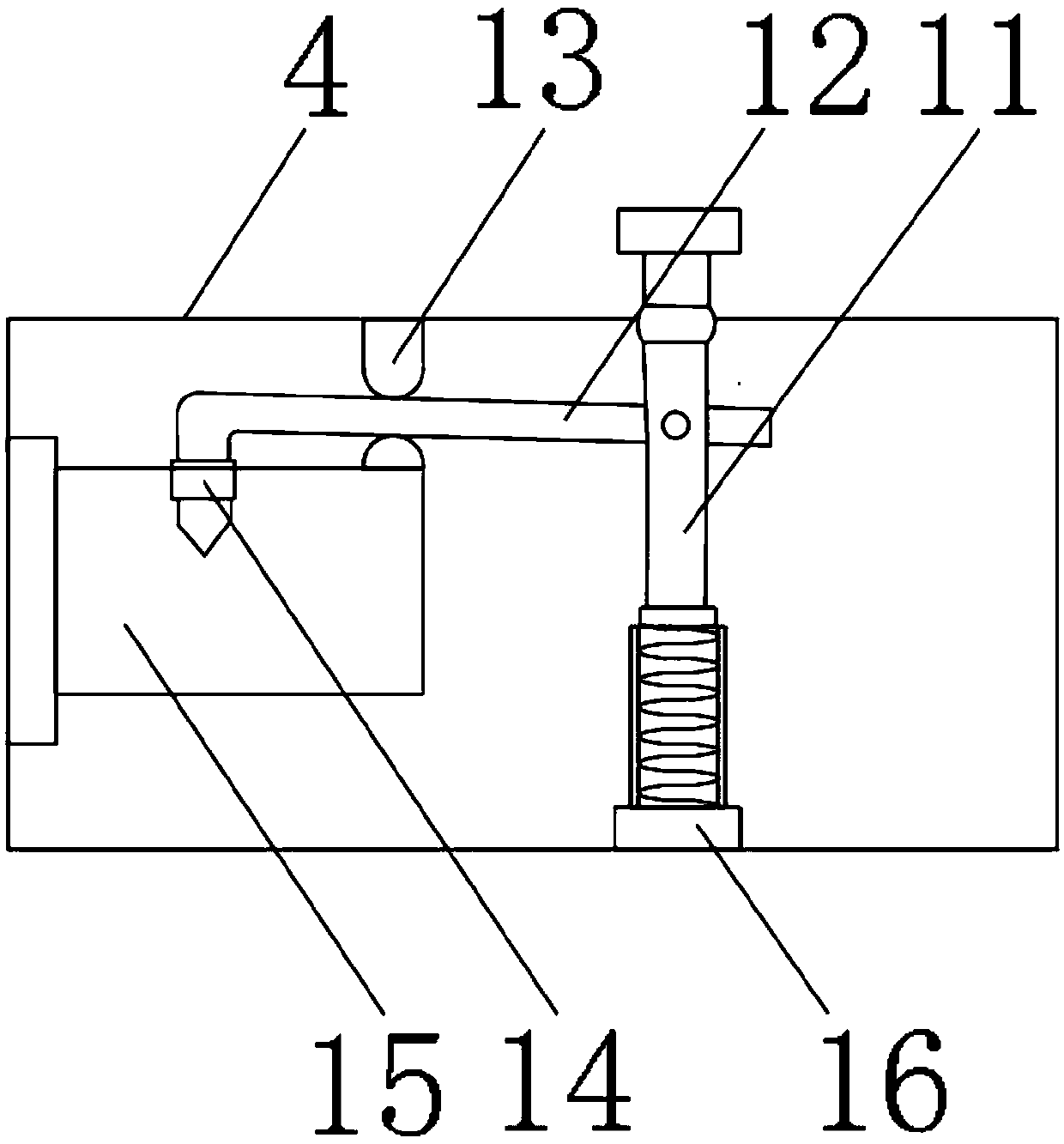

[0020] Such as Figure 1-4 As shown, an industrial production and processing integrated machine includes a protective shell 1, a display screen 2 is arranged at the inner center of the protective shell 1 near the top, a protective shell 3 is fixedly installed on the outer surface of the bottom end of the protective shell 1, and the protective shell 1 is protected. The inside of the shell 3 is provided with a network cable fixing frame 4 near the front end, the bottom end of the protective shell 3 is provided with a connecting plate 5, and the outer surface of the connecting plate 5 is movably mounted with a movable cover 6 near the top position, and the inside of the protective shell 3 is close to two Electromagnetic plates 7 are provided on the side positions, and a spring 8 is provided on the outer surface of the inner side of the protective shell 3 near the position of the electromagnetic plate 7, and a movable pin 9 is installed on one side of the spring 8, and the inner tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com