Plate Separator

A disc separator and separation device technology, which is applied in the field of disc separators, can solve problems such as large structural space, achieve the effects of reducing structural space, reducing structural space requirements, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

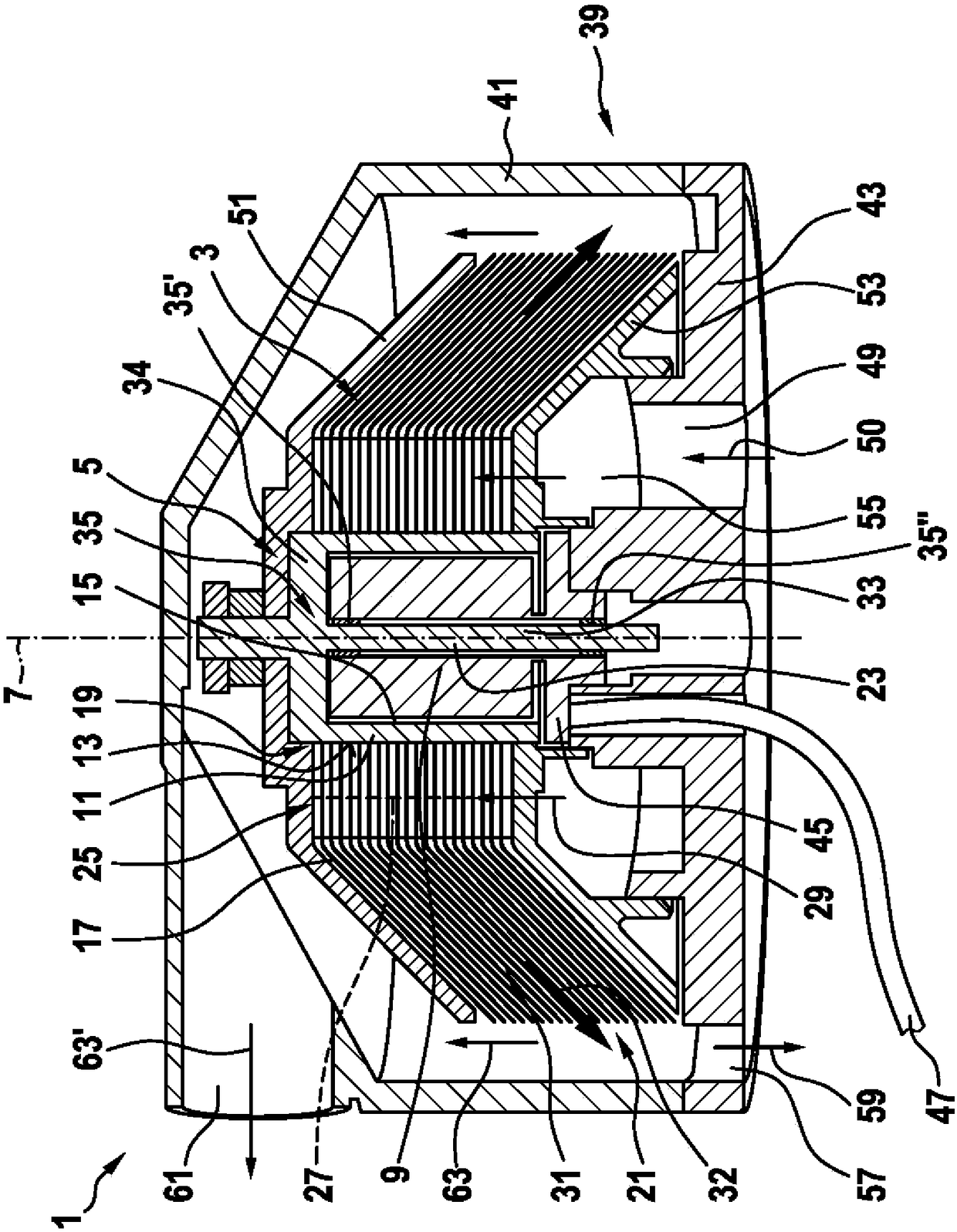

[0023] figure 1 A disc separator 1 for separating material from a material mixture is shown. The disk separator 1 is preferably designed as an oil separator for separating oil from the blow-by gas. The disc separator 1 has a separating device 3 and an electric motor 5 for rotationally driving the separating device 3 . The separating device 3 is coupled in a rotationally fixed manner to an electric motor 5 . The electric machine 5 is designed as an external rotor electric machine and has a radially inner stator 9 with respect to the rotational axis 7 of the electric machine 5 and an outer rotor 11 .

[0024] The rotor 11 here has a substantially cylindrical outer surface 13 . Furthermore, the rotor 11 has an inner side 15 which cooperates with the stator 9 according to the functional principle of known electrical machines.

[0025] The separating device 3 is fastened to the rotor 11 and extends outwards in radial direction from the rotor 11 . The stator 9 at least partiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com