A motor rotor automatic blower

A motor rotor, automatic technology, applied in chemical instruments and methods, cleaning methods using gas flow, cleaning methods and utensils, etc., can solve the problem of difficult cleaning of impurities in rotor grooves, and achieve fast and easy to use. The effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

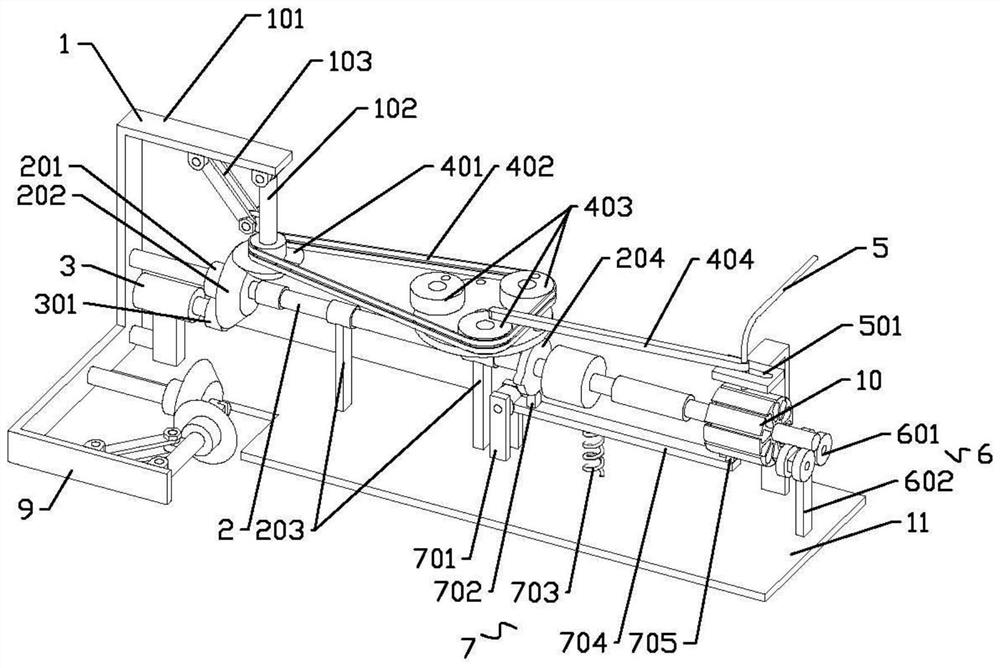

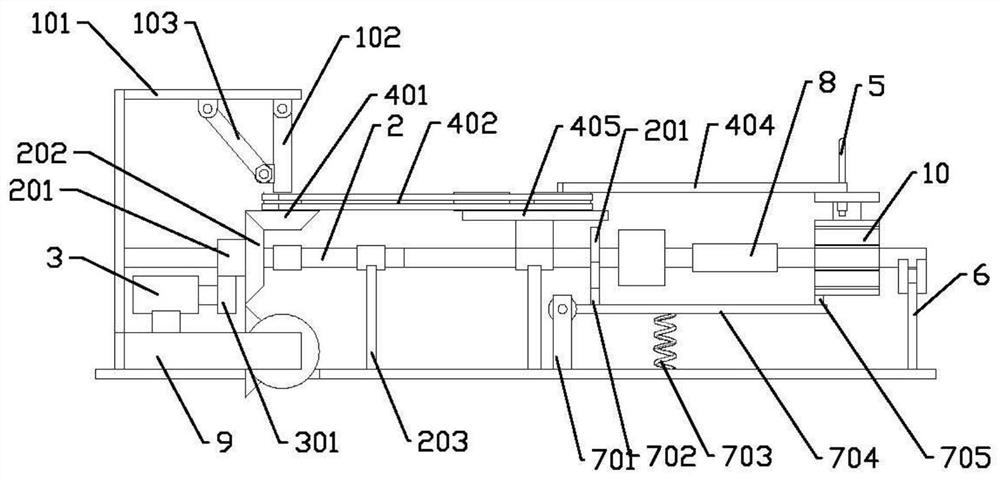

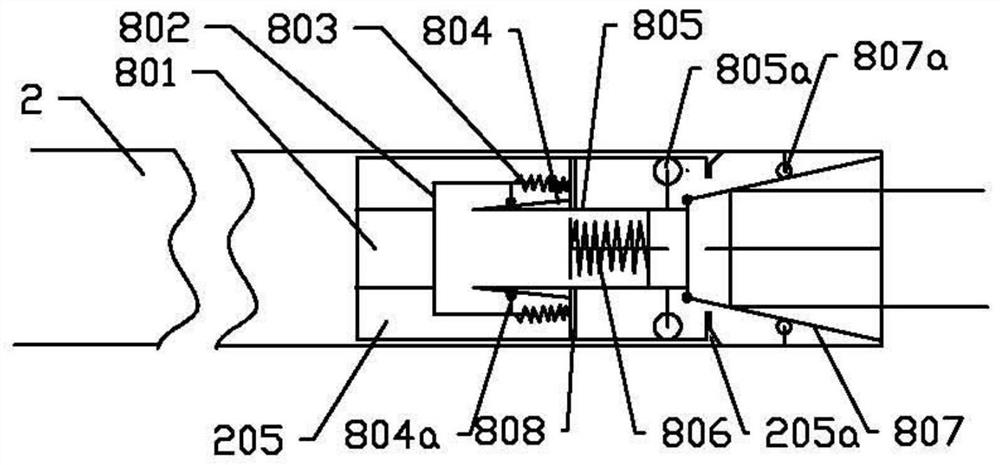

[0037] Such as figure 1 , figure 2As shown, an automatic blower for motor rotor 10 includes a frame 11 and a drive motor 3 mounted on the frame 11, a main shaft 2, a clamping mechanism 8 for the rotor 10, an air pump, a blower head 5, and a rocker drive Mechanism 4, lever 704 locking mechanism 7 and outer roller seat 602. The air pump communicates with the purge head 5 through a pipeline, generates high-pressure gas and discharges it through the purge head 5, and is an important purge component in this embodiment. The leftmost side of the frame 11 is provided with a main bracket 1, and the drive motor 3 is mounted on the left end of the frame 11 to provide power for the operation of the whole machine, and a drive tooth 301 is coaxially fixedly installed on the drive shaft. The main shaft 2 is arranged parallel to the driving shaft of the driving motor 3, and is a long shaft straddling the frame 11 from left to right, and a large bevel gear 202 is fixedly installed on the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com