Smashing device for refuse landfill

A landfill and crushing device technology, which is applied in transportation and packaging, chemical instruments and methods, and solid waste removal, etc. Ingenious design, multi-purpose power source, and volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

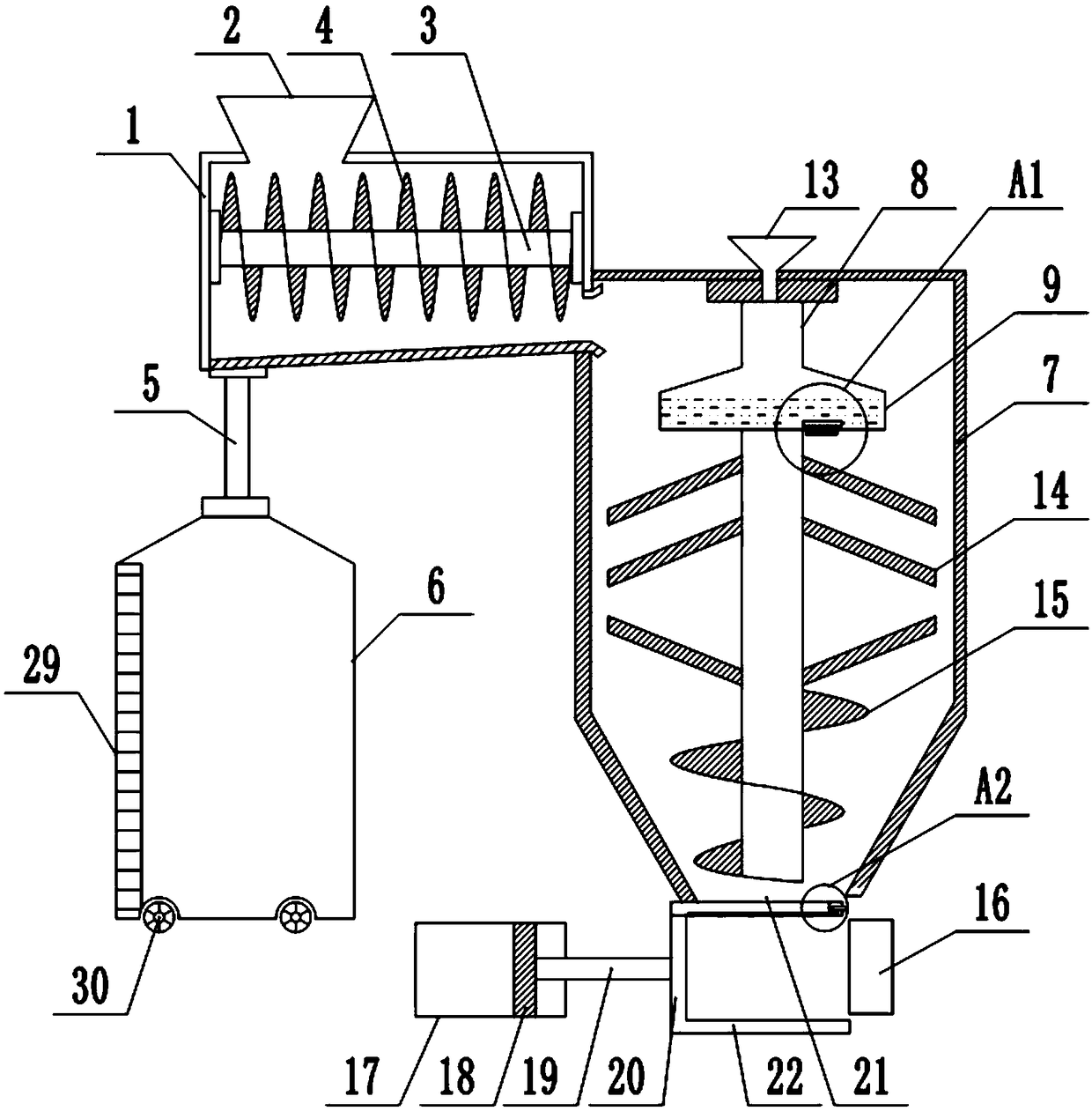

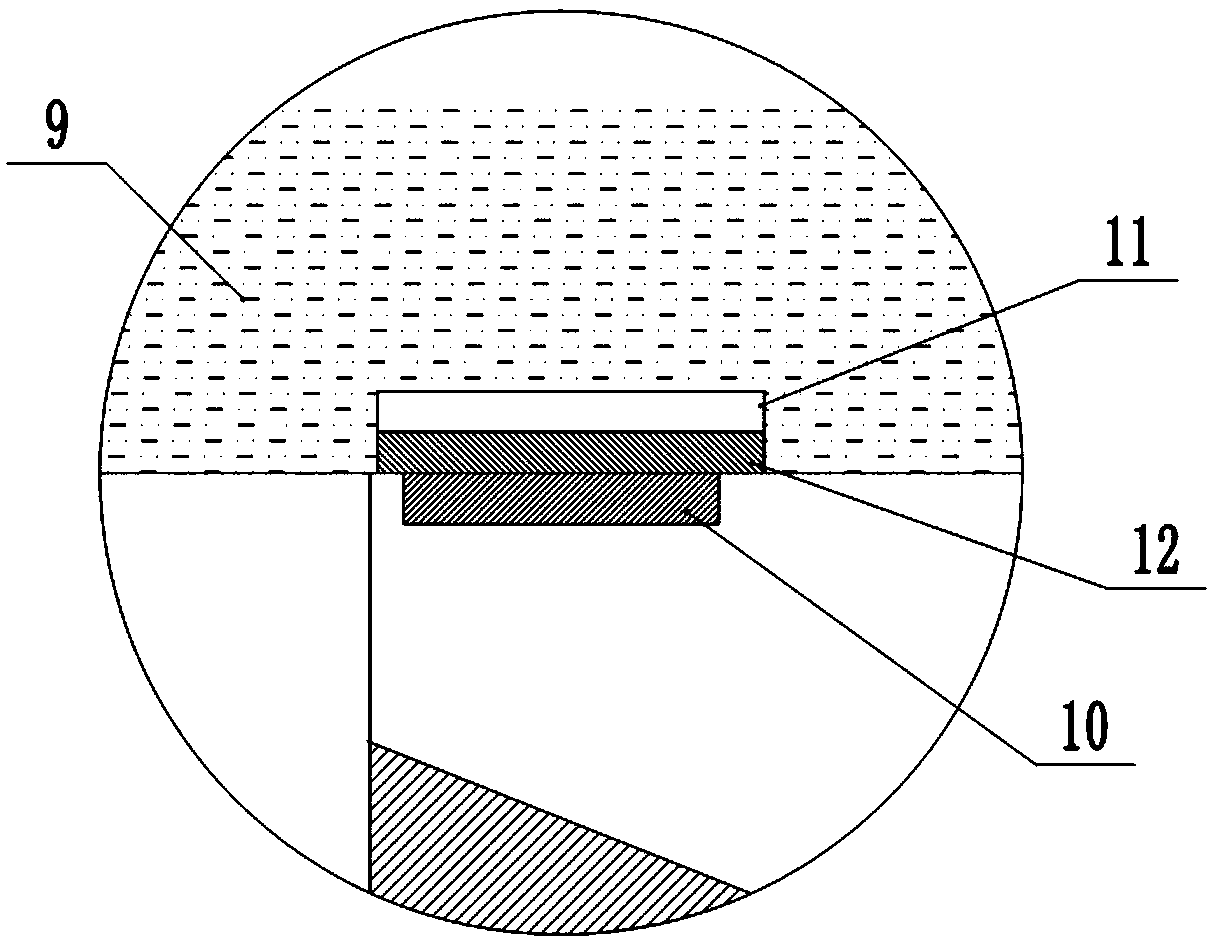

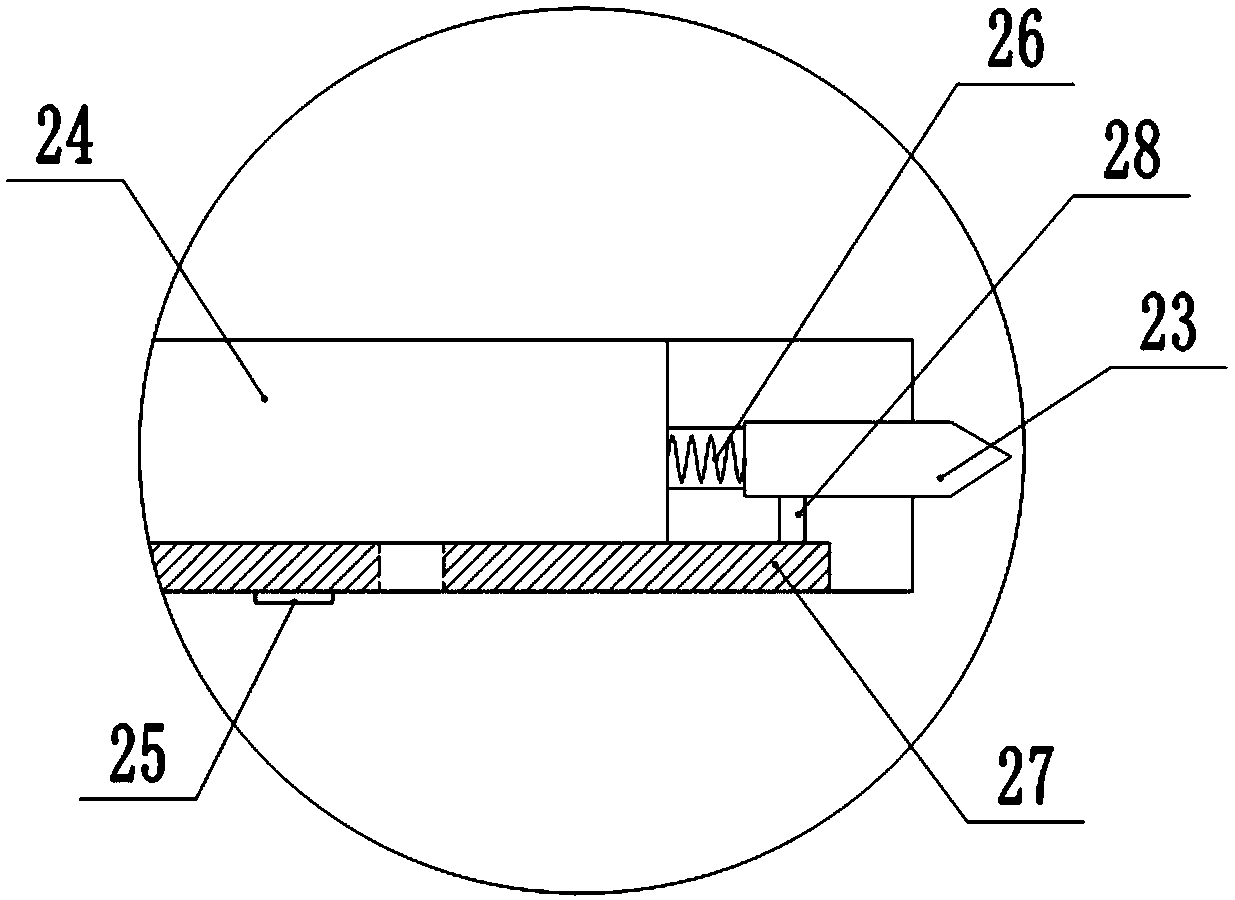

[0021] The reference signs in the drawings of the description include: feed box 1, feed hopper 2, rotating shaft 3, screw feed blade 4, liquid outlet pipe 5, storage tank 6, crushing box 7, crushing shaft 8, spray box 9 , the first magnet 10, the block 11, the second magnet 12, the hopper 13, the crushing blade 14, the spiral feeding blade 15, the fixed plate 16, the cylinder 17, the piston 18, the push rod 19, the vertical plate 20, the upper horizontal Plate 21, lower cross plate 22, cutting knife 23, liquid storage cavity 24, liquid outlet 25, support spring 26, slide bar 27, connecting rod 28, visible window 29, runner 30.

[0022] The embodiment is basically as attached figure 1 Shown: The crushing device for landfill, including feeding mechanism, crushing mechanism and briquetting mechanism. The feeding mechanism includes feeding box 1. The top left side of feeding box 1 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com