Laser welding tool for engine hood of large aircraft

A technology of engine hood and laser welding, which is applied in the direction of laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of part indentation, part pressure deformation, etc., and achieve the effects of convenient operation, shortened welding cycle, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

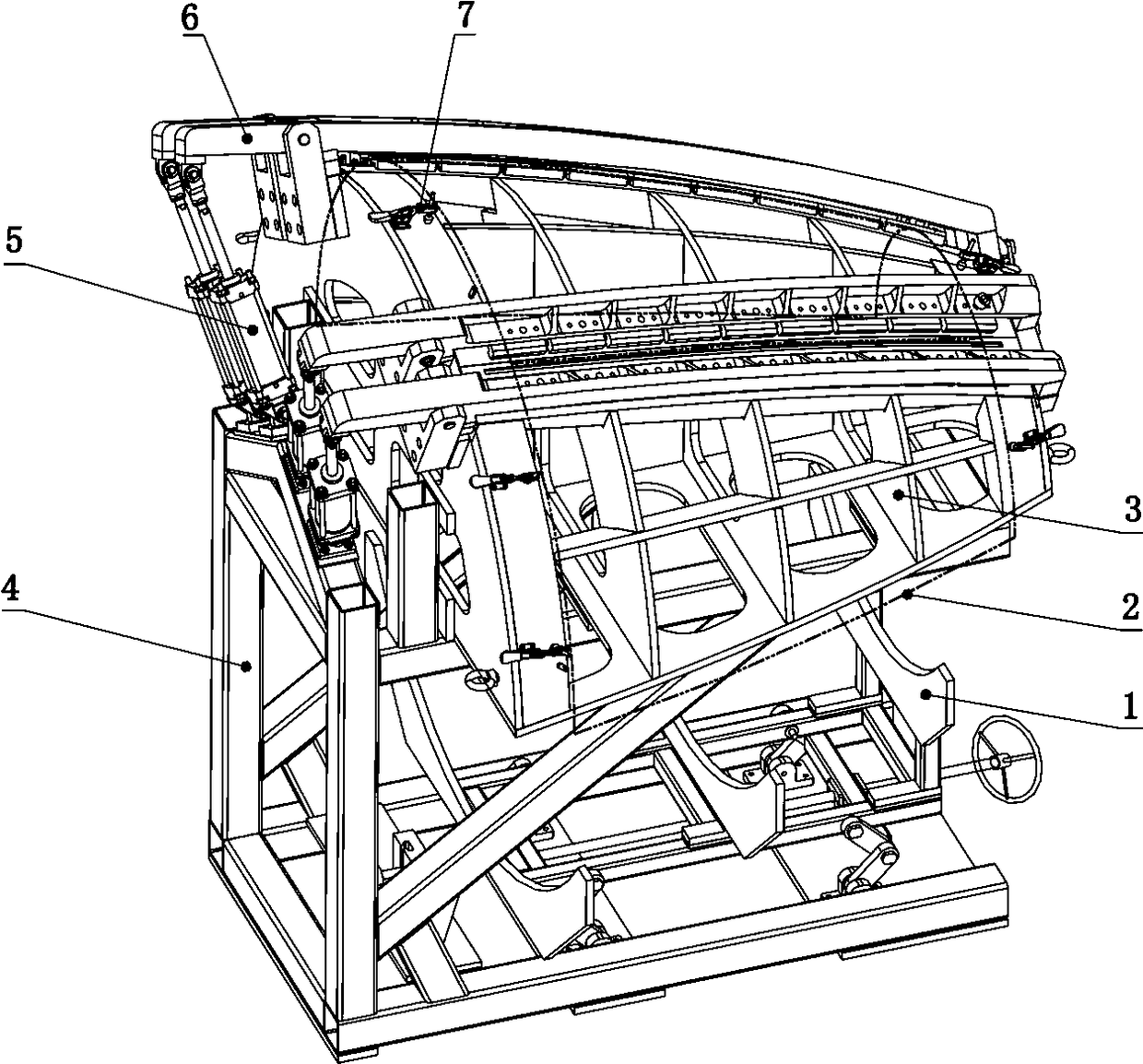

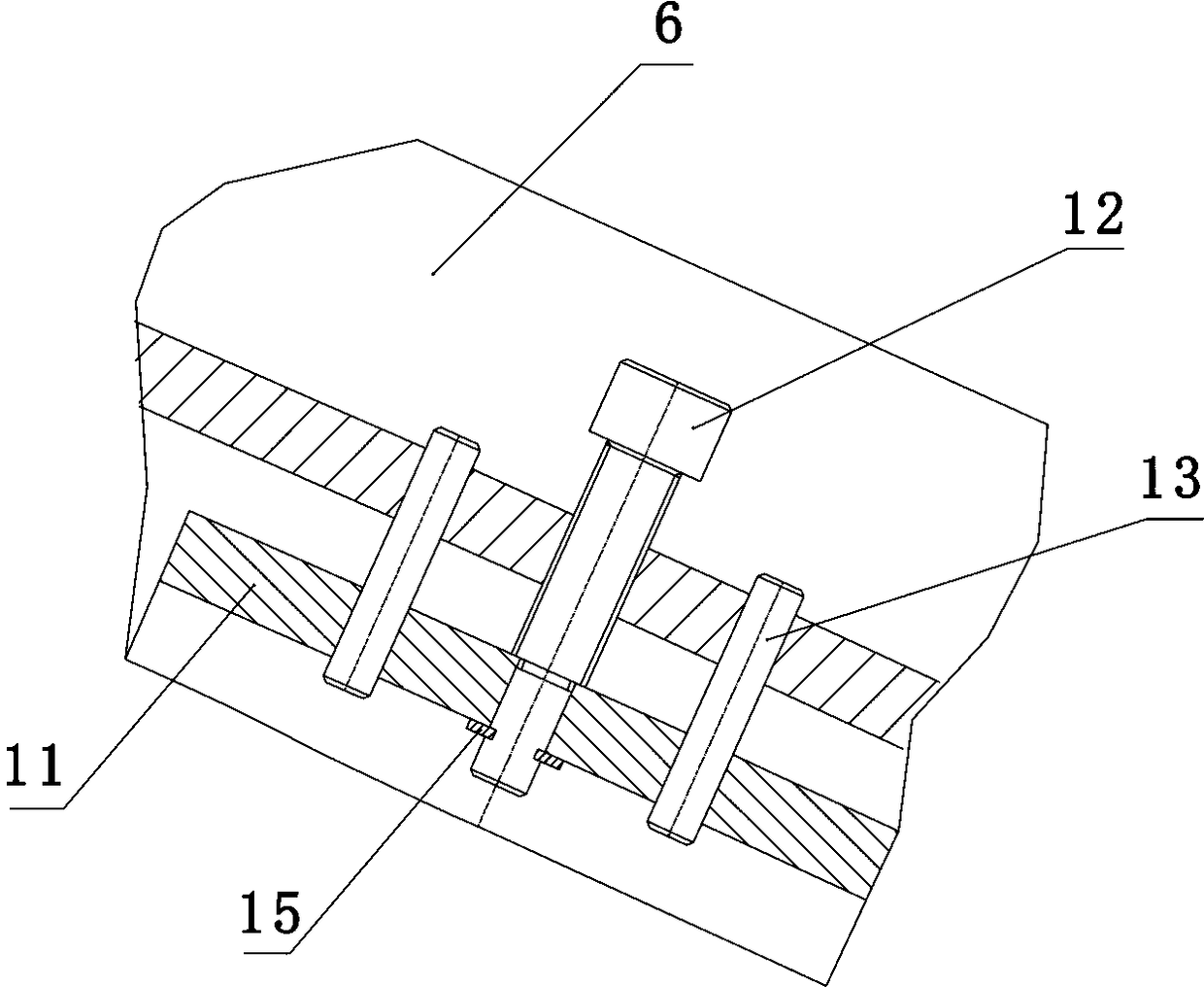

[0034] Such as figure 1 , 2 As shown, the present invention provides a kind of large-scale aircraft engine cover laser welding frock here, comprises mold body frame 3, support frame 4, cylinder 5, crossbeam 6, briquetting block 11, and mold body frame 3 is installed on the support frame 4, supports The frame 4 is also provided with a cylinder mount 8 , and the cylinder 5 is connected to the support frame 4 through the cylinder mount 8 . The mold body frame 3 is provided with a rotating seat 9, and the beam 6 is connected with the mold body frame 3 through a rotating shaft 10 on the rotating seat. One end of the crossbeam is connected with the piston rod of the cylinder, and the reciprocating motion of the cylinder 5 drives the crossbeam 6 to rotate; the other end of the crossbeam is provided with a hook, which is connected with the fixed buckle 14 on the mold body frame to lock the crossbeam 6 and the mold body frame 3.

[0035] The mold body frame is also provided with a f...

Embodiment 2

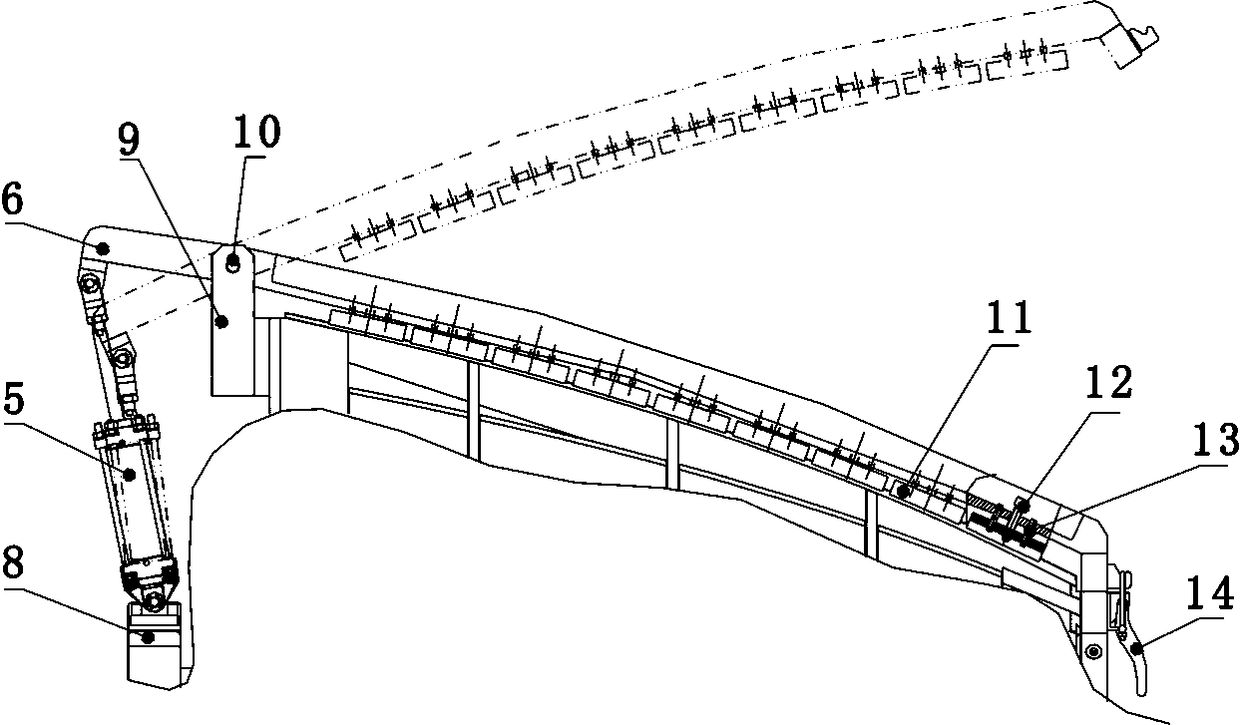

[0039] Such as figure 2 Shown is the working diagram of the beam. On the basis of the above, the present embodiment further optimizes the design: specifically, one end of the mold body frame is provided with a rotating seat 9, and the rotating seat 9 is provided with a rotating shaft 10, and the crossbeam 6 is connected with the mold body frame 3 through the rotating shaft 10. There is a hook at one end of the crossbeam, which is used to connect with the fixed buckle 14 at one end of the phantom frame, so as to realize the locking and fixing of the crossbeam 6 and the phantom frame 3. The other end of the beam is connected with the piston rod of the cylinder, and the cylinder 5 is installed on the support frame 4 . The reciprocating motion of the cylinder 5 drives the beam 6 to rotate around its center of rotation. When the cylinder 5 moves downward, it drives the crossbeam 6 to move upward around the rotating shaft, and the crossbeam 6 is opened and put into the mold body ...

Embodiment 3

[0042] Such as Figure 4 Shown is a schematic diagram of the phantom frame. This embodiment further optimizes the design on the basis of the foregoing embodiments: the profile of the phantom frame is set to be less than a semicircle, the maximum distance of the profile from the center line 16 is L, and the size of L remains at 80-100mm. The parts can be separated from the mold body surface smoothly when the parts are conveniently set up in this way, and the parts will not be scratched by frictional movement on the mold body surface.

[0043] The position of each component on the mold body frame is 0-0.1mm, and the limited position ensures the accurate installation of each component and improves the precision of the processing tooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com