Mechanical arm special for shoe heels

A manipulator and heel technology, which is applied to shoe-making machinery, heel pads, footwear, etc., can solve the problems of low production efficiency and waste of human resources in the heel production process, so as to save labor costs and improve production efficiency. , The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

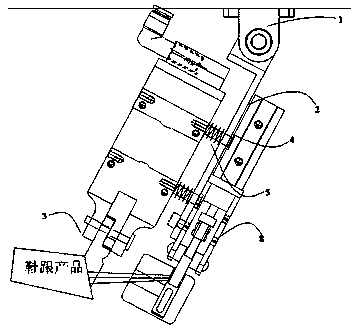

[0022] refer to figure 1 , the present invention relates to a special manipulator for shoe heels, comprising a rotating base 1, a tooling fixing bracket 2 fixed on the rotating base 1 and an air scissors 3, the air scissors 3 are fixed on the tooling fixing frame 2 through a positioning pin 4, and the positioning pin 4 is provided with an elastic body. In this embodiment, the elastic body is preferably a spring 5, so that the scissors can effectively cut flat when they touch the product. The optical fiber switch 6 is fixed on the air scissors 3 through the optical fiber switch fixing block 7 . A fiber optic switch is used to detect the heel.

[0023] One end corresponding to the scissors on the tooling fixing bracket is provided with a clamping device for clamping the material head. In this embodiment, the clamping device is a clamp 8 equipped with a reed switch.

Embodiment 2

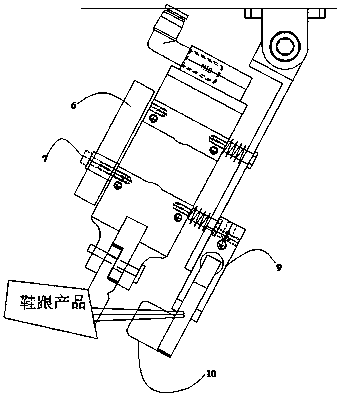

[0025] refer to figure 2 , in this embodiment, the clamping device is a mini clip 9, and two extension blocks 10 are arranged in front of the mini clip, wherein the extension blocks are preferably L-shaped. All the other parts are identical with embodiment 1.

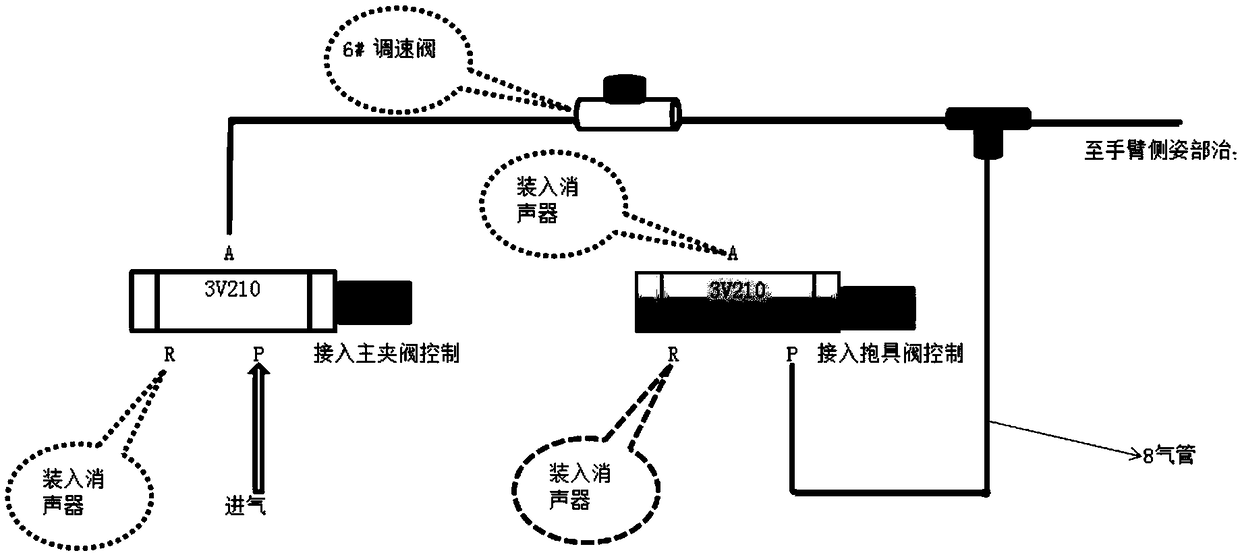

[0026] The working principle of this device is as follows:

[0027] Injection molding machine mold opening in place (signal) - manipulator arm down (special tooling on the arm) - main arm forward - product ejection - main arm clamp (scissors clamp the rod) - auxiliary arm clamp ( Clamp the tail end of the material rod at the same time as the main arm clamp) - the main arm retreats - the product breaks (the scissors cut off the material head and the heel product falls into the water) - the main arm rises - cross out (to the required position) ——Place the auxiliary arm (put the material head at the specified position)——Walk in (to the pick-up position).

[0028] The main arm is the arm where the air scissors are locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com