Automobile battery fixing assembly

A technology for fixing components and automobile batteries, which is applied to vehicle components, electric power devices, power devices, etc., can solve problems such as increased assembly time, uneven force, and increased bolts and nuts, and achieves improved installation stability and disassembly Convenience, anti-cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

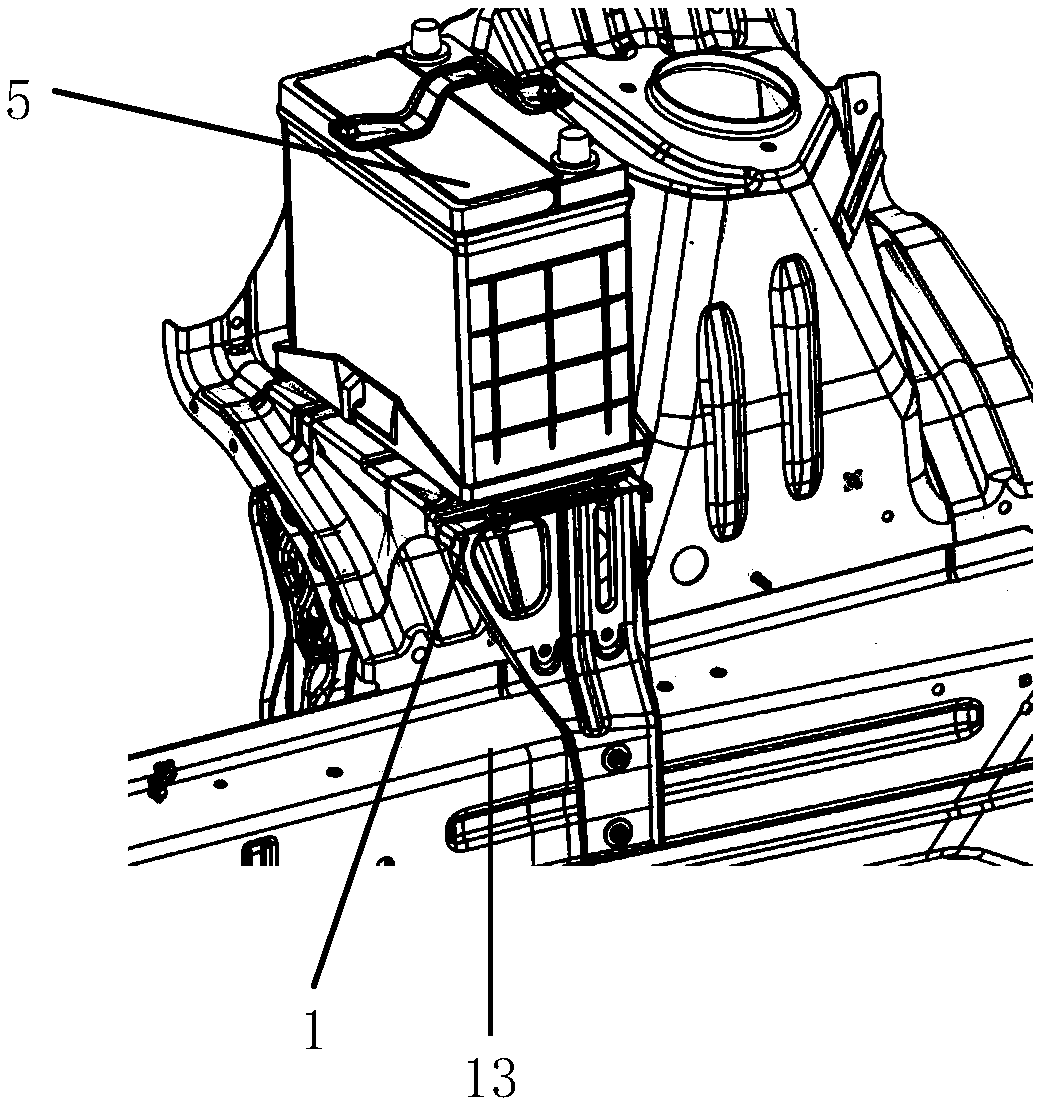

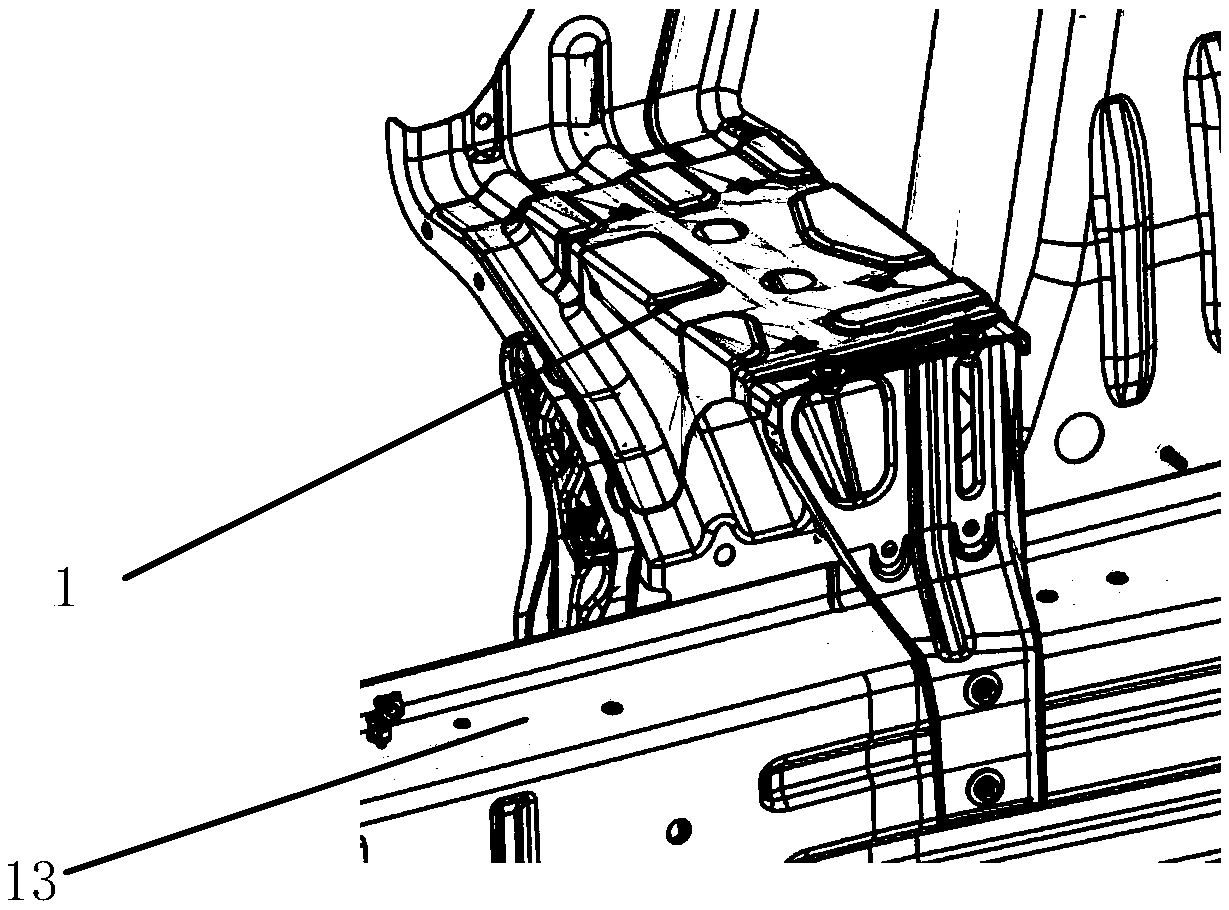

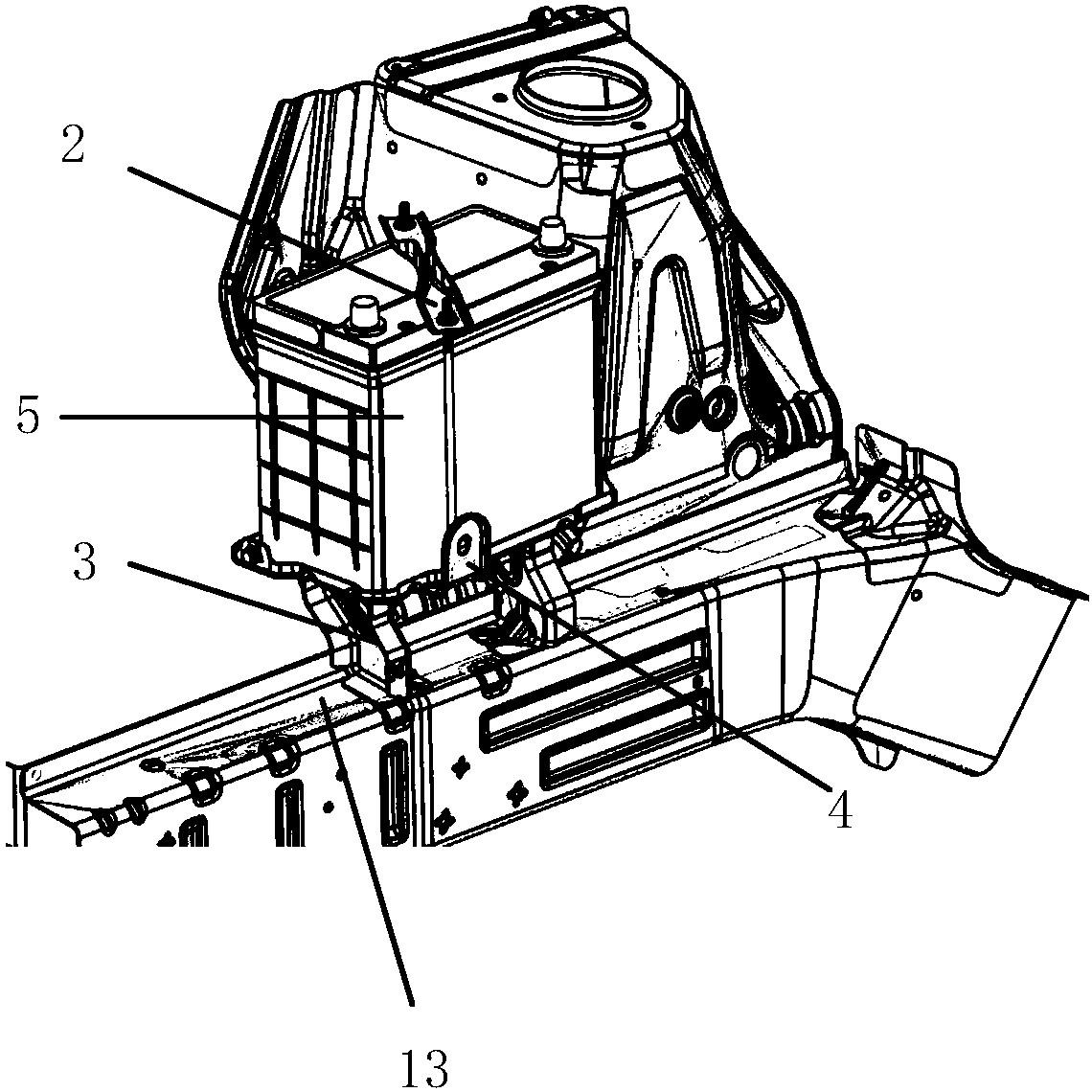

[0035] The following with attached Figure 3 to Figure 13 A car battery fixing assembly of the present invention is further described in detail.

[0036] A kind of automobile battery fixing assembly of the present invention, please refer to Figure 3-13 , including a battery fixing device and a beading device for fixing the battery 5, the beading device is detachably fixed on the battery fixing device, the battery fixing device is fixed directly above the girder 13, and the battery 5 is longitudinally arranged on the on the battery holder described above. In this way, the automotive battery fixing assembly of the present application is a battery fixing device and a beading device, and the battery fixing device is arranged directly above the girder 13. When assembling the battery 5, the battery 5 is placed on the battery fixing device, and the beading device is pressed. On the battery 5, and detachably fixed on the battery fixing device, so that the battery 5 is fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com