Water gas filtration device

A filter equipment, water gas technology, applied in the direction of gas dust removal, combustible gas purification, combustible gas purification/transformation, etc., can solve the problems of aggravated product dirt, waste of labor, poor filtering effect, etc., to improve product quality and reduce labor intensity , Solve the effect of burner coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

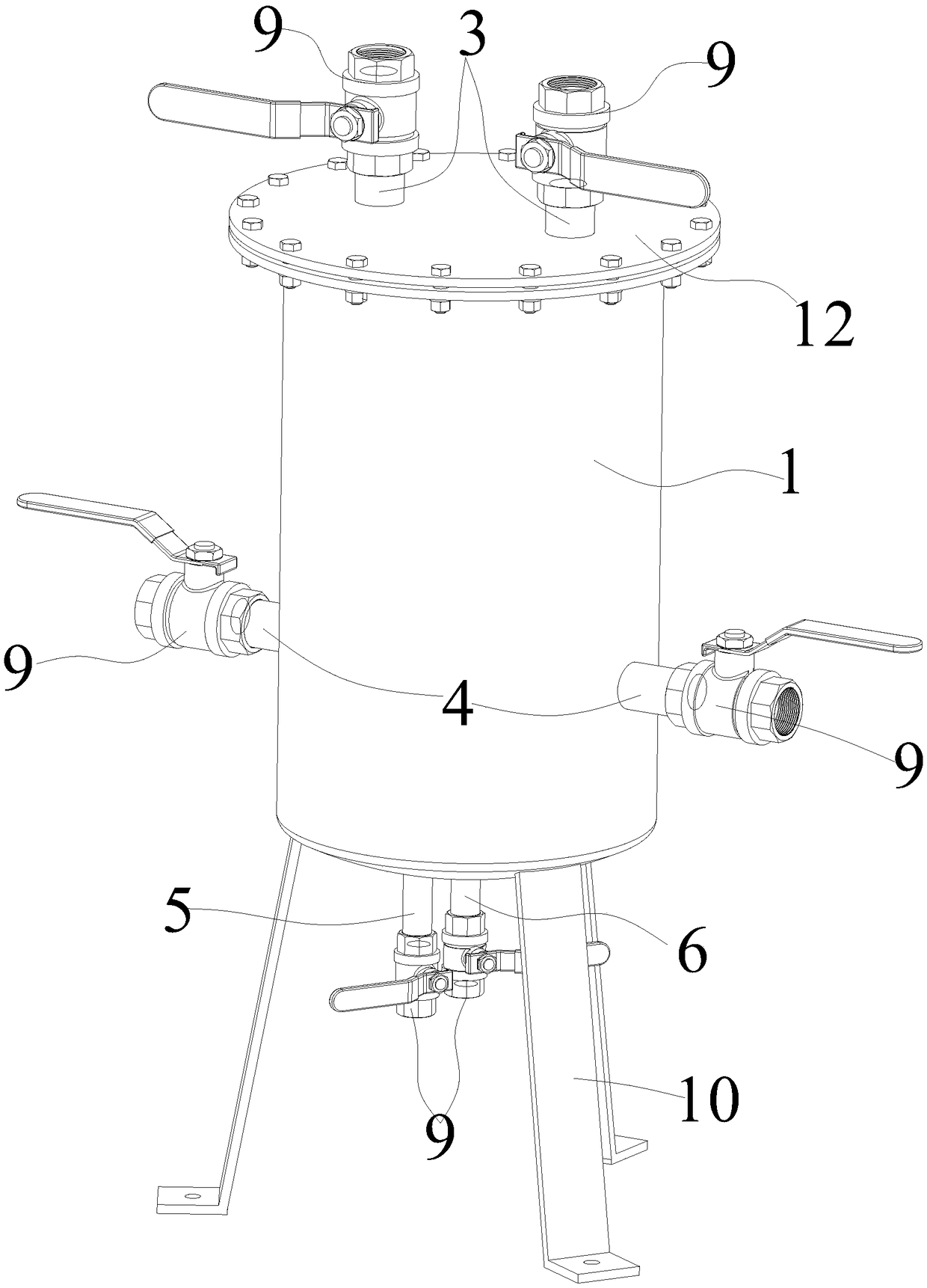

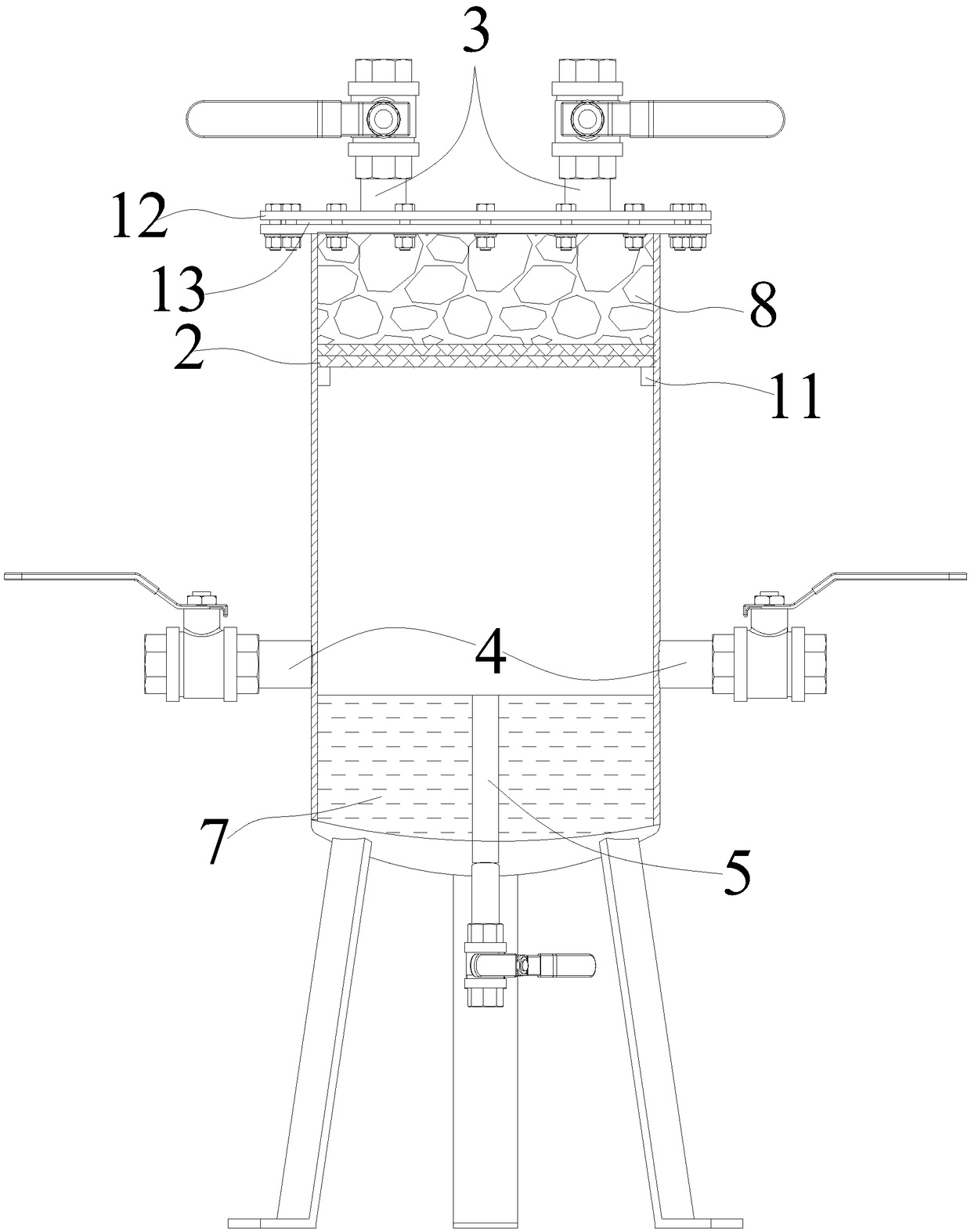

[0025] Attached below Figure 1-2 The present invention is described in further detail.

[0026] Figure 1-2 Schematically shows that according to an embodiment of the present invention, a water gas filtering device is provided, including a filter bucket 1, a filter screen 2 is provided in the filter bucket 1, and two air outlets 3 are provided on the upper end surface of the filter bucket 1, and the filtering Both sides of the outer wall of the barrel 1 are provided with an air inlet 4, one end of the bottom of the filter barrel 1 is provided with an overflow pipe 5, and the other end of the bottom of the filter barrel 1 is provided with a sewage outlet 6, and the filter barrel 1 is filled with condensate 7.

[0027] The water gas enters the filter barrel 1 from the air inlet 4. Since the air inlet 4 is directed downward, the pressure of the water gas itself is used to punch down the condensate 7 in the filter barrel 1, and the condensate in the filter barrel 1 is used to 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com