Heat dissipation device for oil pump

A heat dissipation device and oil pump technology, which is applied in the field of heat dissipation devices of oil pumps, can solve the problems that the relative position of the oil pump and the oil pump motor controller is not easy to determine, the design of the connecting pipeline is complicated, and the pipeline is aging and leaking, so as to improve the reliability of the system , Easy installation, save the effect of connecting pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

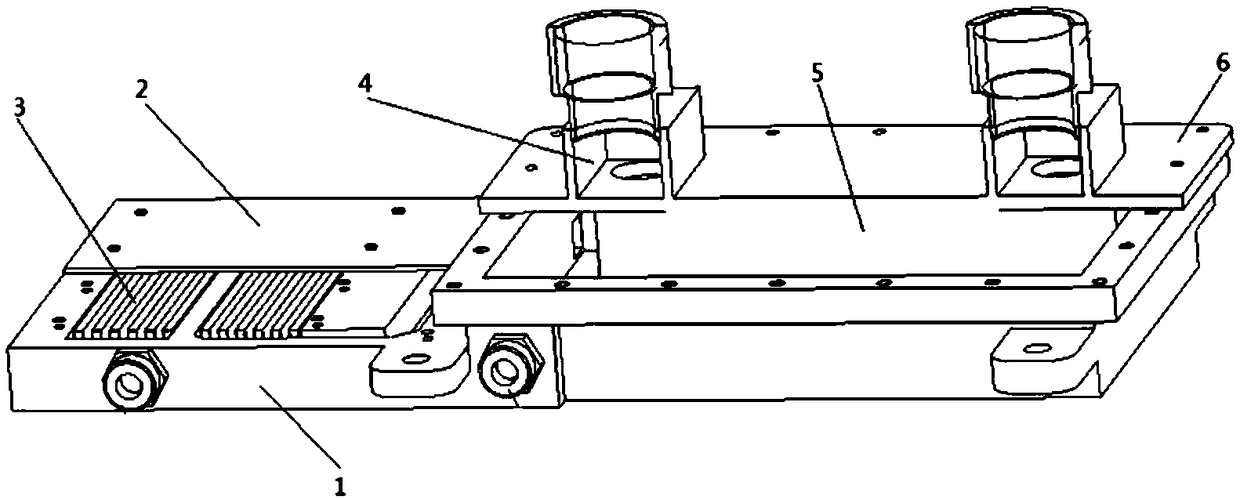

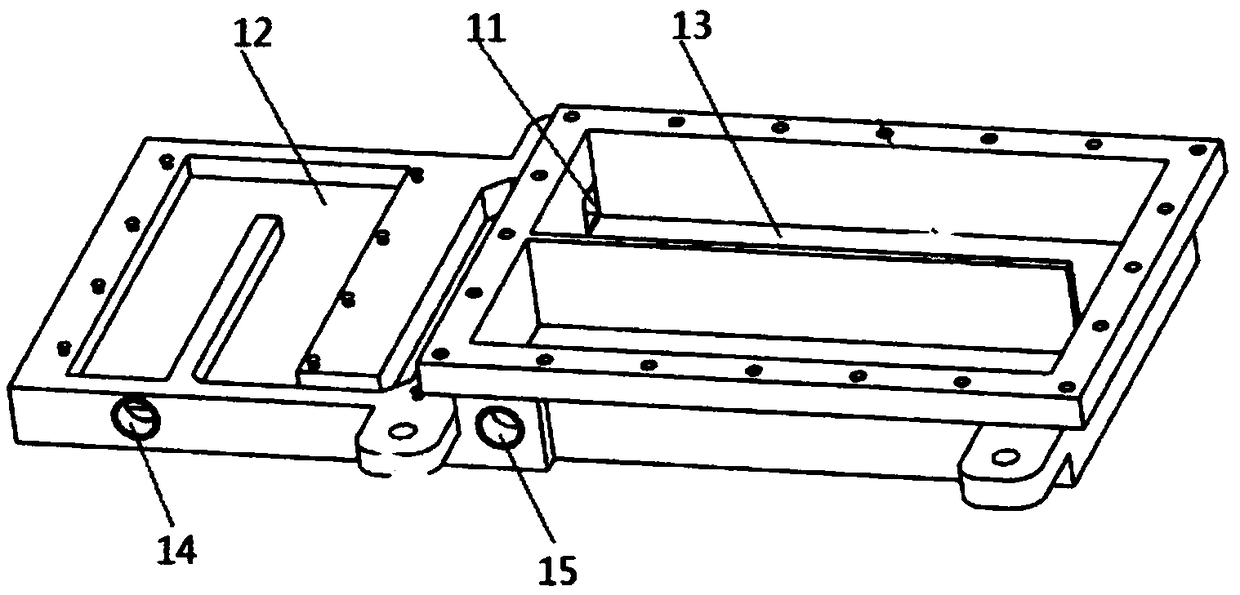

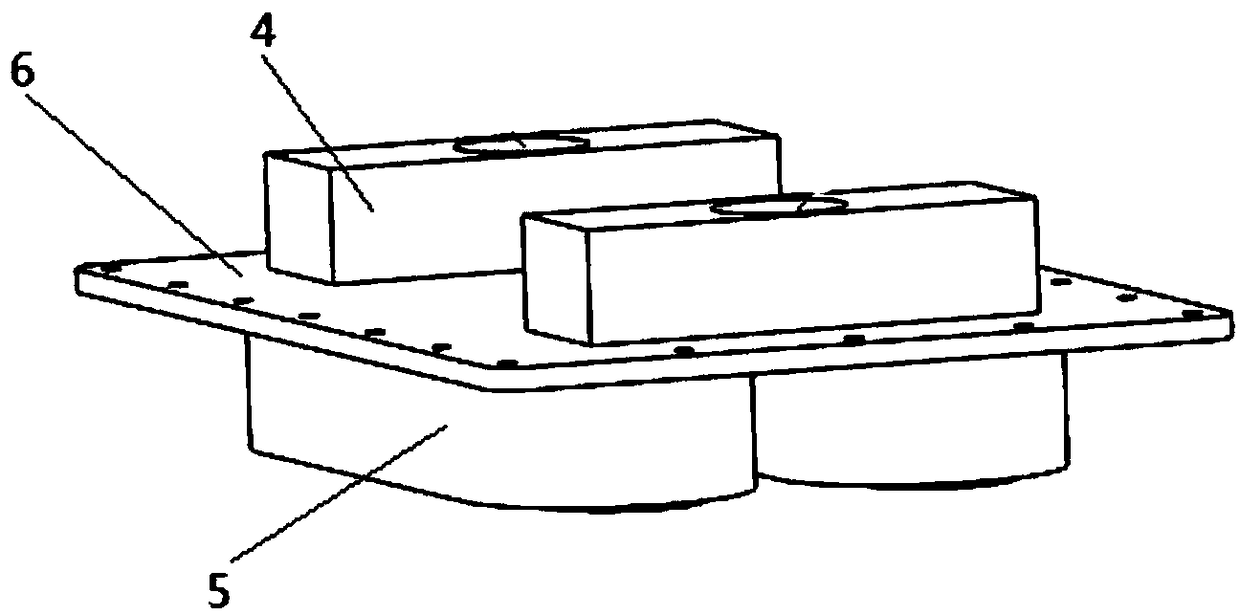

[0036] In order to better understand the present invention, the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0037] Such as Figure 1 to Figure 5 As shown, the heat dissipation device for the oil pump provided by the present invention, the oil pump includes: a motor and a hydraulic oil tank, the motor includes: a motor controller IGBT module 7, and the heat dissipation device is arranged on the motor controller IGBT module 7 Below, the IGBT module 7 includes: a control board 7-4, a drive board 7-3, a gate plate (7-2) and an IGBT element 7-1 arranged in sequence; the heat dissipation device includes: a horizontally arranged groove 1 and an oil component located above the tank 1 and connected to the hydraulic oil tank; the tank 1 is a rectangular water-cooled tank composed of left and right water tanks; the left water-cooled tank 12 is arranged on the IGBT element 7-1 The lower end, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com