High-pressure high-purity hydrogen manufacturing and adding all-in-one machine

An all-in-one, hydrogen technology, applied in gas/liquid distribution and storage, mechanical equipment, fluid processing, etc., can solve problems such as traffic safety hazards, high cost of hydrogen storage tanks, safety hazards, etc., and achieve the effect of meeting emergency needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention are described below through specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

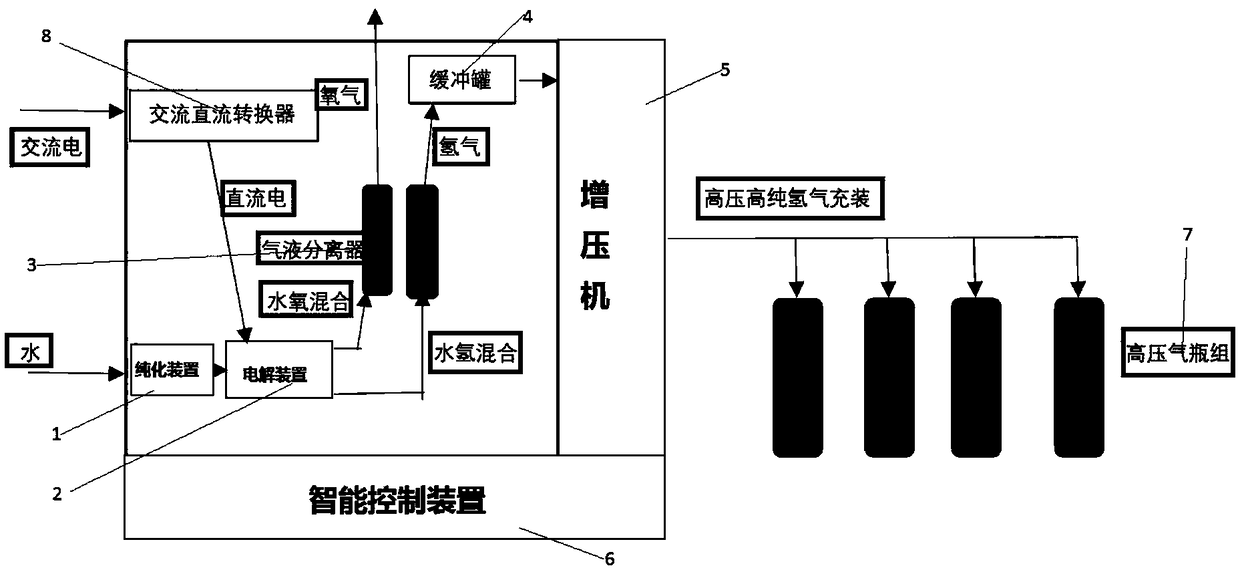

[0023] Such as figure 1 As shown, the high-pressure high-purity hydrogen hydrogen production and hydrogenation integrated machine includes a purification device 1, an electrolysis device 2, a gas-liquid separation device 3, a buffer device 4, a booster device 5, and an intelligent control device 6. The purification device 1 and The electrolysis device 2 is connected, and then the gas-liquid separation device 3 is connected, the gas-liquid separation device 3 is connected to the buffer device 4, the buffer device 4 is connected to the booster device 5, and the intelligent control device 6 is connected to the electrolysis device 2 and the booster device through a power line or a signal line 5. The purification device 1 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com