Rubber pipe online high-pressure and constant-pressure testing system

A pressure testing and rubber hose technology, applied in the field of rubber hose online high-pressure constant pressure testing system, can solve problems such as quality management risks, low production efficiency, and inability to collect data, so as to facilitate data collection and big data processing, and improve work Quality, preparation time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

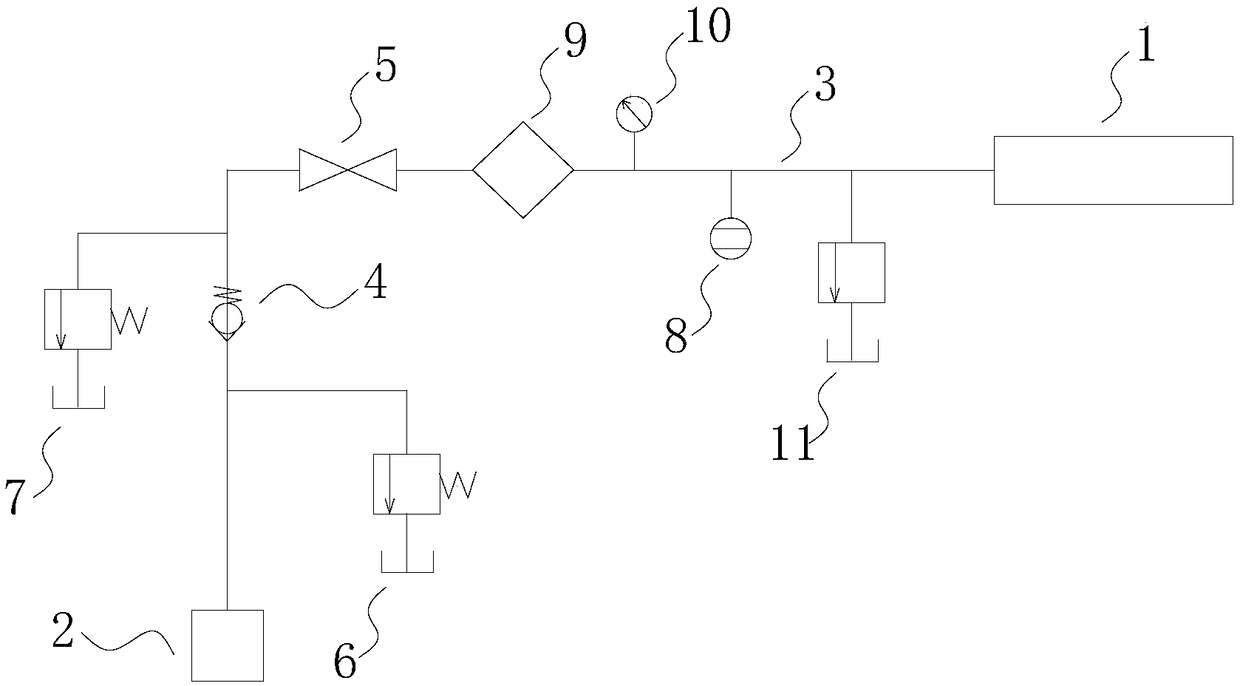

[0027] Such as figure 1 As shown, a rubber hose online high-pressure constant pressure testing system includes a control terminal, a pressure test container 1 made of rubber hose with an opening at one end, a high-pressure pump 2 and a conduit 3. The inlet of the conduit 3 is connected to the high-pressure pump 2 Outlet, the outlet of the conduit 3 communicates with the opening of the pressure test vessel 1; the conduit 3 from the high pressure pump 2 to the pressure test vessel 1 is sequentially provided with a one-way valve 4 and a pneumatic shut-off valve 5; the high pressure pump 2 and the one-way A pump end unloading valve 6 is arranged on the conduit 3 between the valves 4; a container unloading valve 7 is arranged on the conduit 3 between the one-way valve 4 and the pneumatic stop valve 5; the pneumatic stop valve 5 and the test The conduit 3 between the pressure vessels 1 is provided with pressure detection equipment; the high-pressure pump 2, pneumatic stop valve 5, p...

Embodiment 2

[0033] This embodiment is a further improvement made on the basis of Embodiment 1. The difference between this embodiment and Embodiment 1 is:

[0034] The high-pressure pump 2 described in this embodiment is a high-pressure water pump installed in the water source, and the high-pressure water pump is used to inject water into the conduit 3 for high-pressure constant pressure testing, especially suitable for the pressure test container 1 with a large volume, and can be filled with tap water Fill water into the pressure test vessel 1. When filling water, pay attention to exhaust the air as much as possible. You can set an exhaust port on the pressure test vessel 1. The exhaust port is generally set above the vessel. It is required that the low-pressure water inlet hole and the high-pressure water inlet hole should be separated. After the water injection is completed, manually close the gate valve of the low-pressure water inlet hole, and then use the rubber hose online high-pres...

Embodiment 3

[0041] This embodiment is a further improvement made on the basis of embodiment 1 or embodiment 2. The difference between this embodiment and embodiment 1 or embodiment 2 is:

[0042] Preferably, a high-pressure filter 9 is provided on the conduit 3 between the pressure detection device and the pneumatic shut-off valve 5 . The high-pressure filter 9 is suitable for filtering solid and liquid impurities in high-pressure compressed air, ensuring that only particles with a particle size smaller than the required size can enter, and providing system accuracy.

[0043] Preferably, a pressure gauge 10 is provided on the conduit 3 between the pneumatic shut-off valve 5 and the pressure test vessel 1, which is convenient for observing the pressure on site, and is cheap and practical.

[0044] Preferably, the outlet end of the conduit 3 is provided with a manual unloading valve 11 . The manual unloading valve 11 can be used after the pressure maintaining is completed, and the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com