Method for measuring asphalt content and asphalt-aggregate ratio in asphalt mixture

A technology for asphalt mixture and asphalt content, which is applied in the direction of weighing by removing certain components, can solve problems such as potential safety hazards, the accuracy of test results needs to be improved, and errors, and achieves convenient operation, low test cost, and high accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

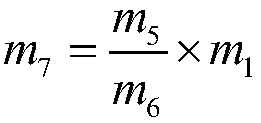

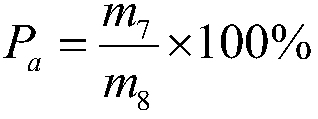

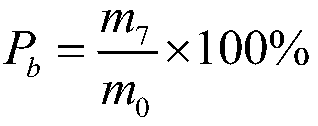

[0077] The invention provides a method for determining the asphalt content and the asphalt ratio in an asphalt mixture. The raw materials and equipment used in the determination method include:

[0078] Asphalt mixture sample: Marshall test piece or asphalt pavement cut (clean and dust-free) 3kg~5kg;

[0079] Trichlorethylene: analytically pure;

[0080] Closed electric furnace: adjustable temperature control, 1000w;

[0081] Hot blast drying oven: adjustable temperature control, 1500w;

[0082] Electronic analytical balance: precision 0.1mg, maximum capacity 210g;

[0083] Electronic balance: precision 0.01g, maximum capacity 5000g;

[0084] Centrifuge: The highest speed is 16500r / min.

[0085] The test steps of the assay method include:

[0086] Step 1. Take about 1 kg of the prepared asphalt mixture sample (Marshall test piece or asphalt pavement cut), weigh it accurately, and record the mass as m 0 , precision 0.01g;

[0087] Step 2. Put the weighed asphalt mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com