Ceramic lattice

A technology of ceramics and grids, applied in the field of ceramic grids, which can solve the problems of increased resistance and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

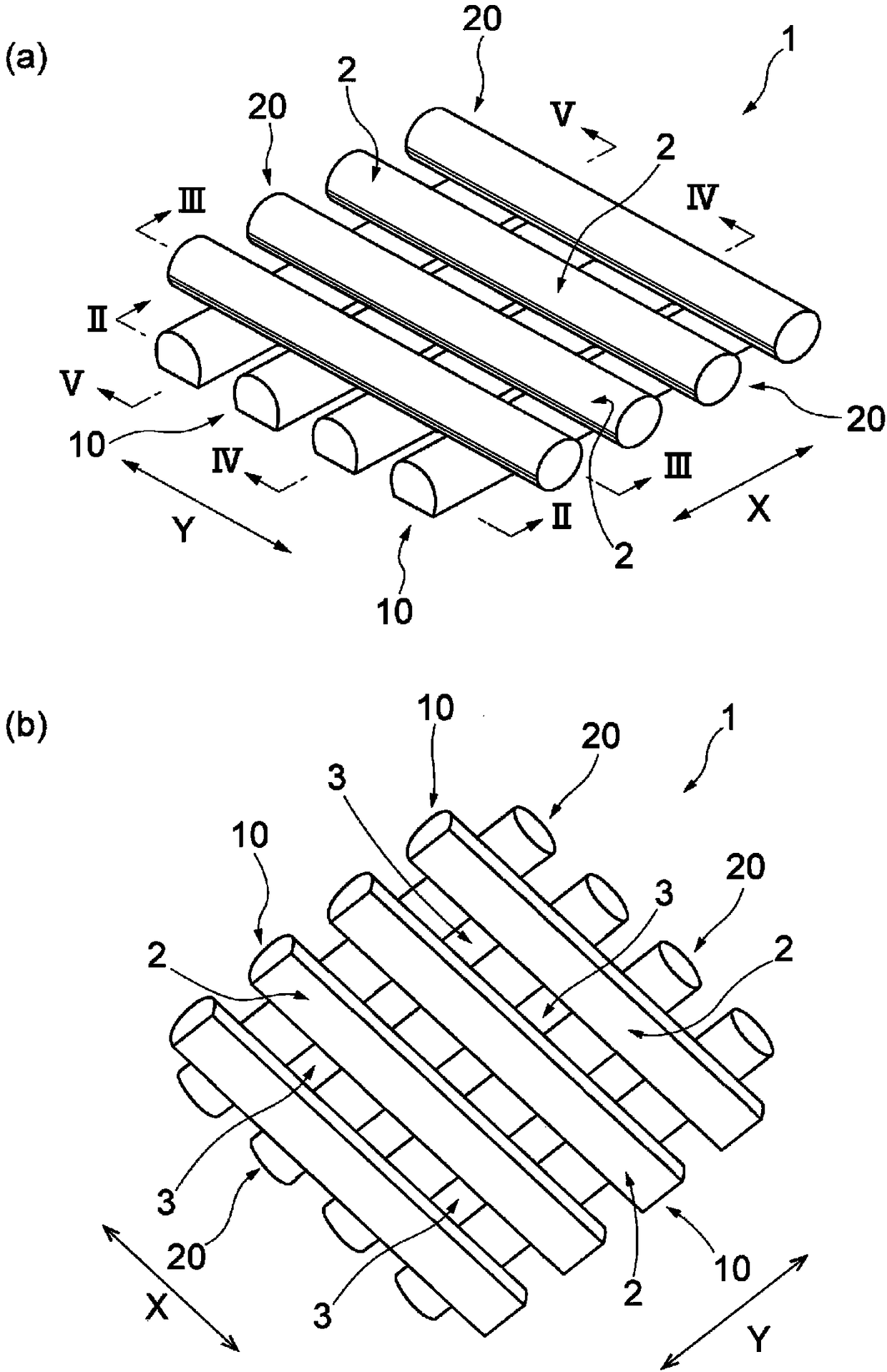

[0096] This example produced Figure 1 to Figure 8 The ceramic grid body 1 shown.

[0097] (1) Preparation of paste for forming line-coated body

[0098] 65.3 parts of 3 mol% yttria-added partially stabilized zirconia powder with an average particle diameter of 0.8 μm, 5.0 parts of hydroxypropyl methylcellulose (average degree of polymerization: 300,000 g / mol) as a water-based binder, as 2.5 parts of glycerin as a plasticizer, 1.1 parts of a polycarboxylic acid-based dispersant (molecular weight: 12,000), and 26.1 parts of water were mixed and defoamed to prepare a paste. The viscosity of the paste was 2.3 MPa·s at 25°C.

[0099] (2) Formation of line coating body

[0100] Using the above-mentioned paste as a raw material, a line first coating body was formed on a resin substrate using a dispenser having a nozzle having a diameter of 0.4 mm. Next, hot air was blown on the first line-coated body using a dryer to remove water, and the first line-coated body was dried. The w...

Embodiment 2

[0104] This example produced Figure 9 ~ Figure 14 Shown is a ceramic grid body 1A.

[0105] (1) Preparation of paste for forming line-coated body

[0106] Add 65.3 parts of fully stabilized zirconia powder to 8 mol% yttrium oxide with an average particle diameter of 0.8 μm, and 5.0 parts of hydroxypropyl methylcellulose (average degree of polymerization: 300,000 g / mol) as a water-based binder, as 2.5 parts of glycerin as a plasticizer, 1.1 parts of a polycarboxylic acid-based dispersant (molecular weight: 12,000), and 26.1 parts of water were mixed and defoamed to prepare a paste. The viscosity of the paste was 2.3 MPa·s at 25°C.

[0107] (2) Formation of line coating body

[0108] Using the above-mentioned paste as a raw material, a line first coating body was formed on a resin substrate using a dispenser having a nozzle having a diameter of 0.4 mm, and then a line second coating body crossing it was formed. The intersection angle of the two-line coating body was set to ...

Embodiment 3

[0112] A ceramic grid body was obtained in the same manner as in Example 2 except that the diameter of the nozzle was set to 0.8 mm. As far as the obtained grid body is concerned, if Figure 14 As shown in , the corners of the rectangular through-holes are rounded.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com