Microchannel reactor for 2-cyanopyrazine preparation

A technology of microchannel reactor and cyanopyrazine, which is applied in chemical/physical/physical chemical reactors, chemical instruments and methods, chemical/physical/physical chemical processes, etc., can solve the problem of low safety and inability to realize mass production and other issues, to achieve the effect of high safety, favorable catalysis, rapid heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

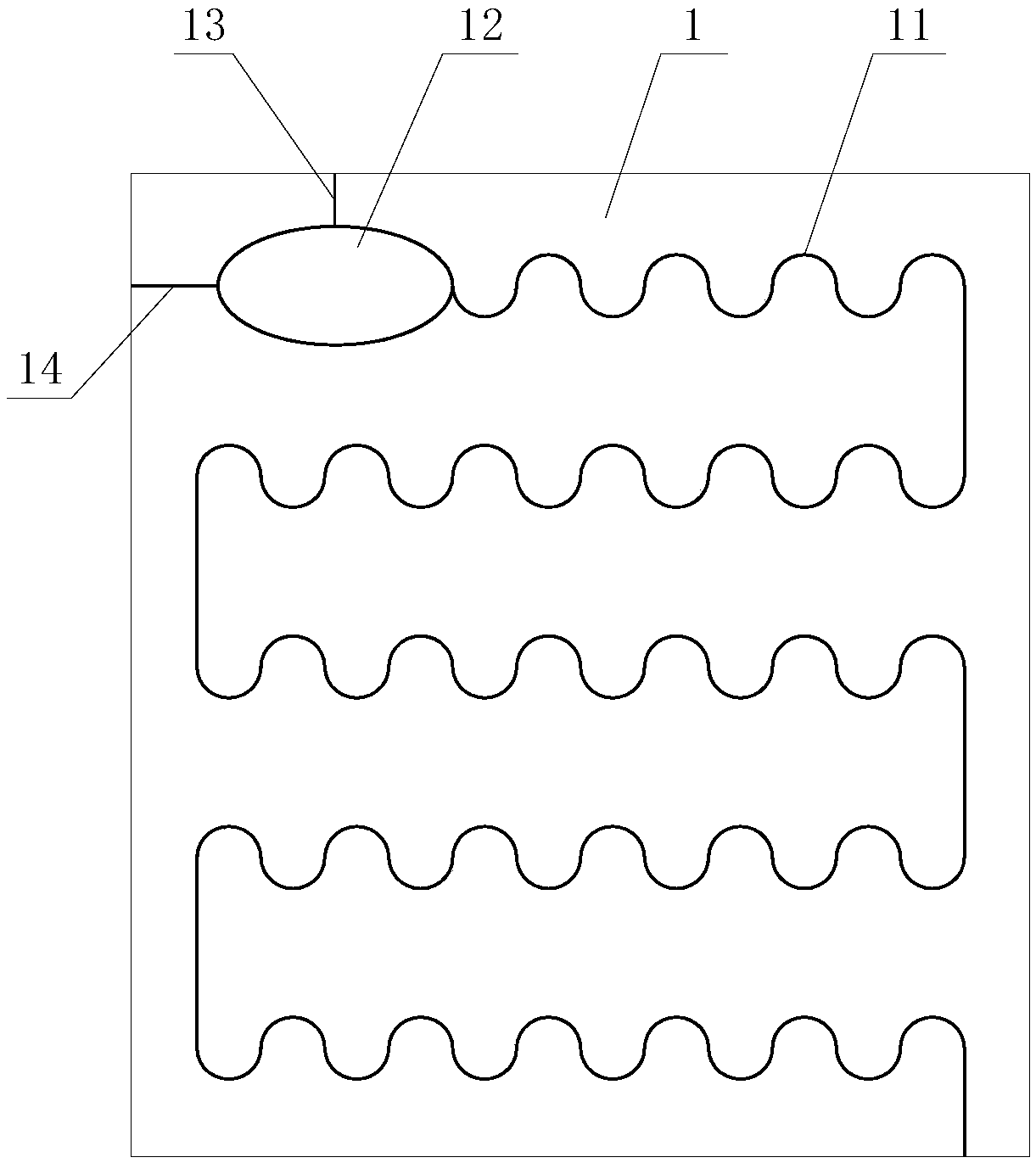

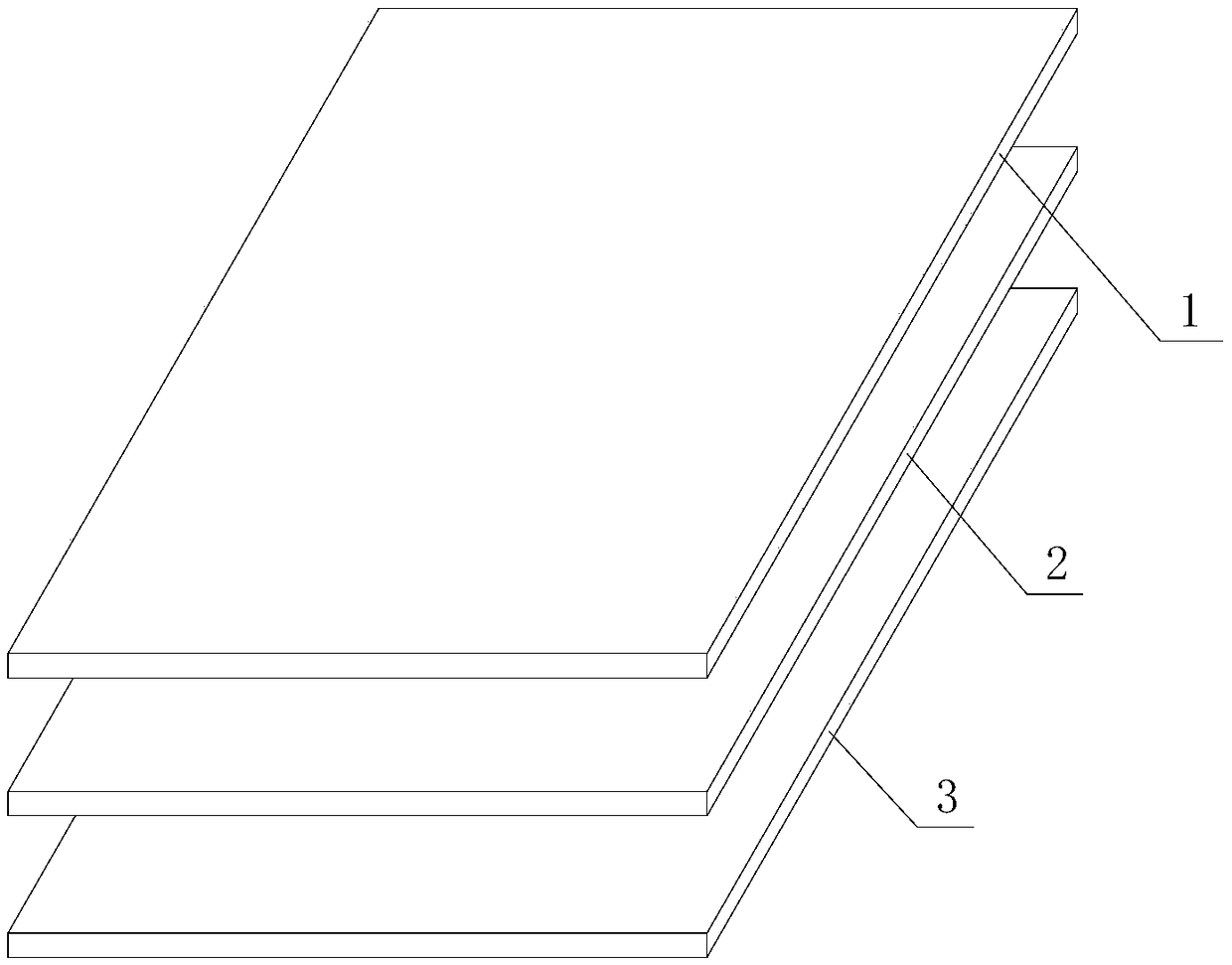

[0017] Such as figure 1 , figure 2 As shown, the present invention includes a stacked microchannel plate 1 and a sealing plate 2. The side of the microchannel plate 1 close to the sealing plate 2 is provided with an etching groove 11. After the etching groove 11 is bonded to the sealing plate 2 A microchannel is formed, and the inlet end of the etching groove 11 is provided with a gasification groove 12, and the gasification groove 12 is respectively provided with a liquid inlet 13 and a gas inlet 14 to communicate with the outside world. During production, the length and cross-sectional area of the etching tank 11 can be designed according to the gas flow rate, the time required for the reaction, etc. The gasification tank 12 is a tank-shaped structure with a slightly larger area, which is mainly used for pre-mixing of gas-liquid two-phase , and its size is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com