Novel micro-motion boring cutter structure

A boring tool and a new type of technology, applied in the accessories of tool holders, tools for lathes, turning equipment, etc., can solve the problems of complex design, complex manufacturing, and many processing procedures, and achieve increased processing range and tool head manufacturing. The effect of simplicity and miniaturization of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

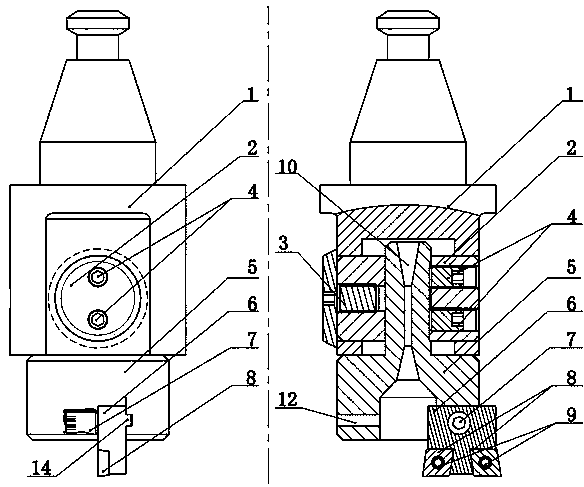

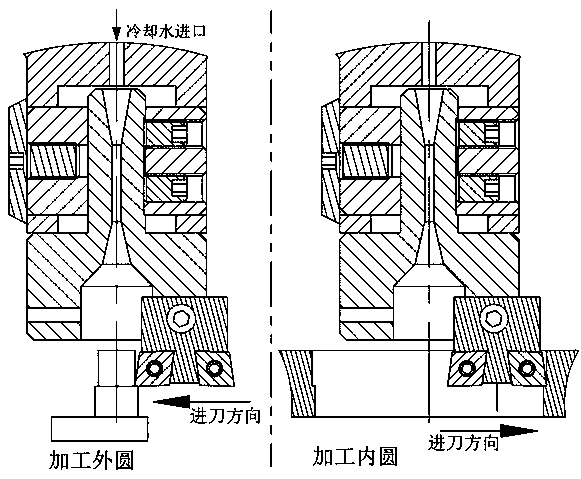

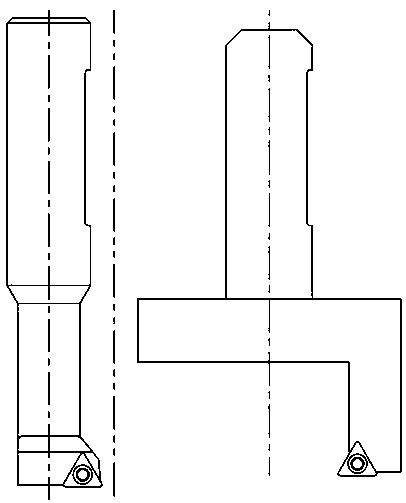

[0023] Such as figure 1 , figure 2 , Figure 4 , Figure 5 A new type of micro-motion boring tool structure of the present invention is shown, including a main body 1, a sliding device 2 installed on one side of the main body 1, a micro-motion adjustment device 3 installed on the other side of the main body 1, a tool bar 5, and a cutter head 6 , the blade 8; the cutter bar 5 and the cutter head 6 are split structures; the inside of the cutter bar 5 is provided with a water outlet 10 that runs through the cutter bar 5, and the upper part of the cutter bar 5 is installed in the main body 1 and passed through the locking screw 4 Connected to the sliding device 2, the lower part of the cutter bar 5 is in the shape of a cylinder, and a rectangular notch 11 is provided at the bottom of the cutter bar 5; one side of the rectangular notch 11 is provided with a c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap