Stacking frame for concrete prefabricated slab type component

A technology of prefabricated slabs and concrete, which is applied in the direction of external frames, load-hanging components, types of packaging items, etc., can solve the problems of limited stacking quantity and inability to make full use of the vertical space of the stacking yard, and achieve floor space saving, Realize batch hoisting and reduce the area occupied by the construction site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

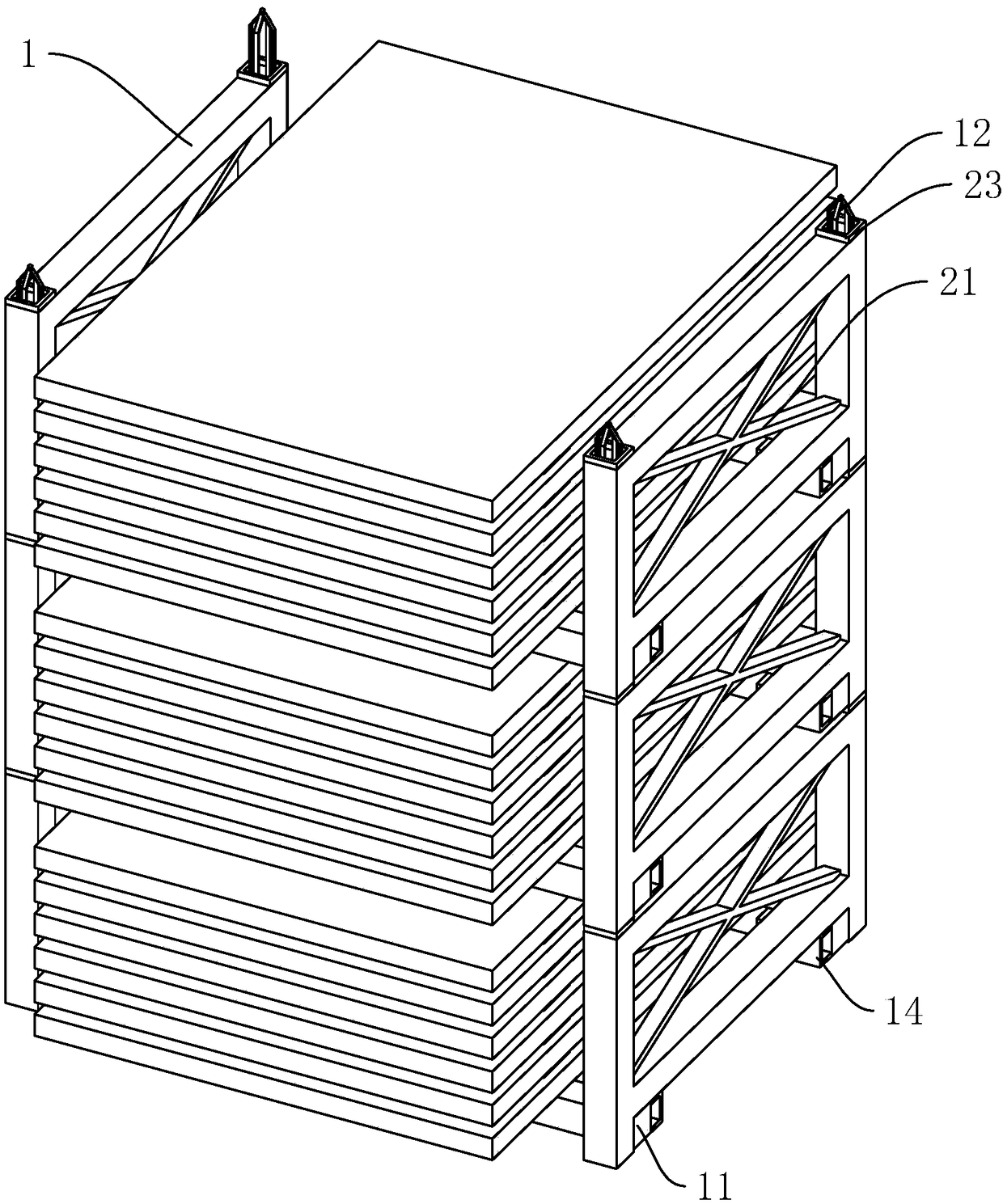

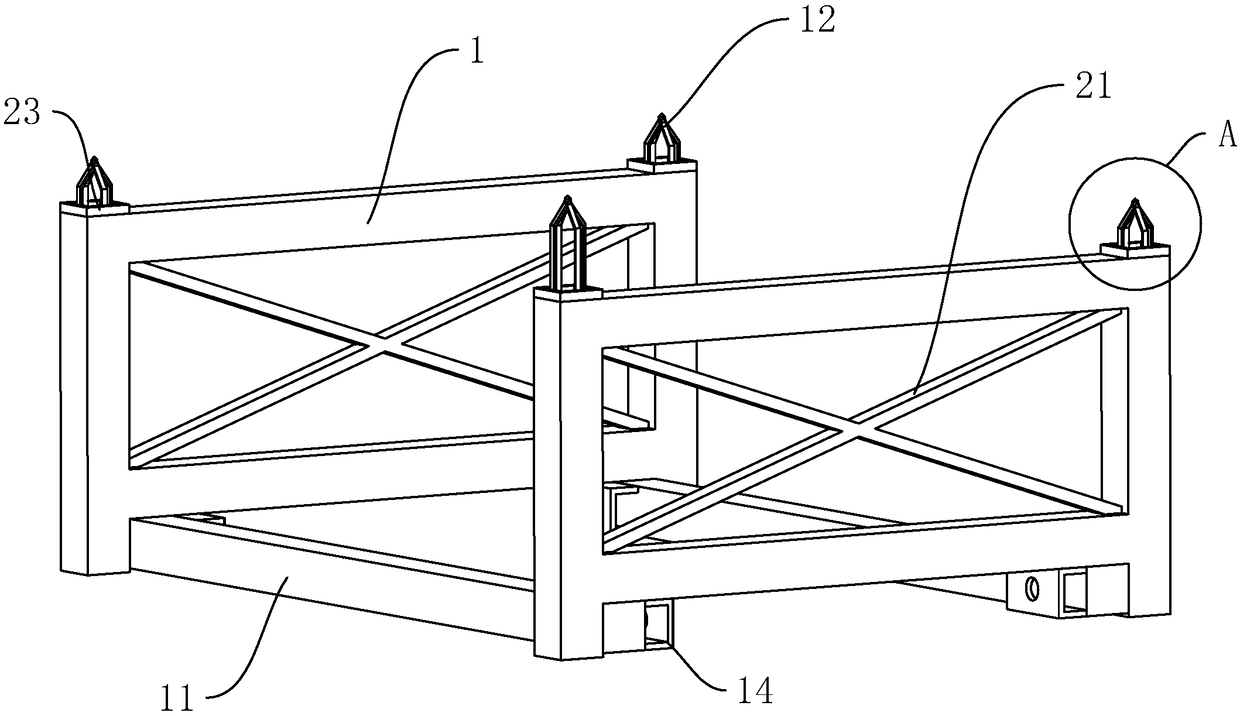

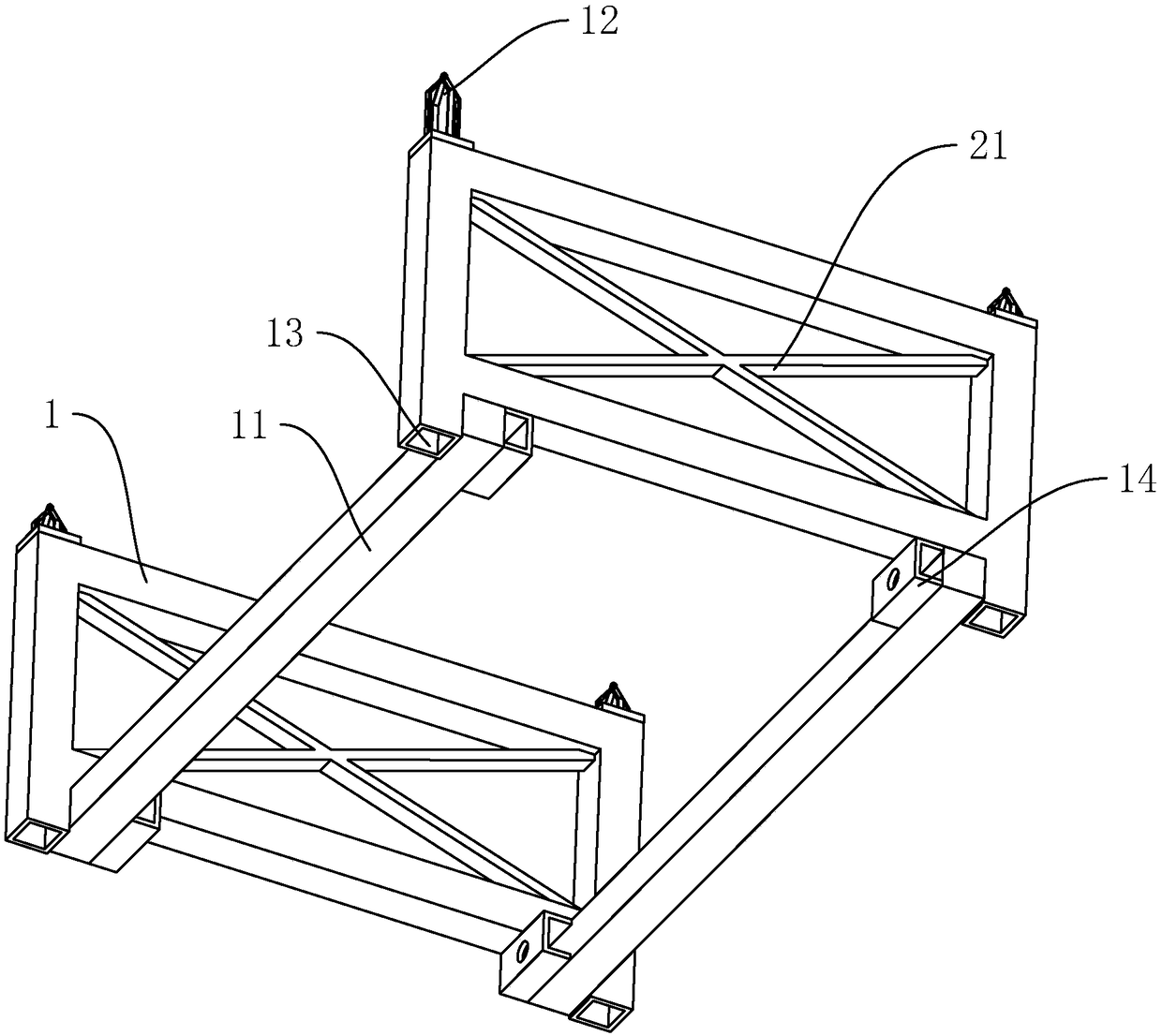

[0030] Stacking racks for concrete prefabricated slabs, such as figure 1 , figure 2 , image 3 As shown, it includes two oppositely arranged rectangular frames 1, and bottom beams 11 welded to both ends of the rectangular frame 1 at the same time. , so that two rectangular frames 1 cooperate with two bottom beams 11 to form a U-shaped placement structure in front view; the two sides of the top of the rectangular frame 1 are respectively provided with socket parts 12, and the two sides of the bottom of the rectangular frame 1 are respectively reserved for The insertion hole 13 into which the insertion part 12 is inserted.

[0031] When it is necessary to stack and stack concrete precast slabs, stack six concrete precast slabs in each stacking rack, lift two stacking racks in turn to align each socket 12 with the corresponding socket hole 13, and will be ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com