Fish-scale flaky semi-straight-pipe coke oven ascending pipe waste heat recovery apparatus

A waste heat recovery device, flap-type technology, applied in the heating of coke ovens, coke ovens, carbonization gas discharge devices, etc., can solve the problems of poor heat exchange effect, less waste heat recovery, device leakage, etc., and achieve waste heat utilization Good effect, prolong service life, good heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

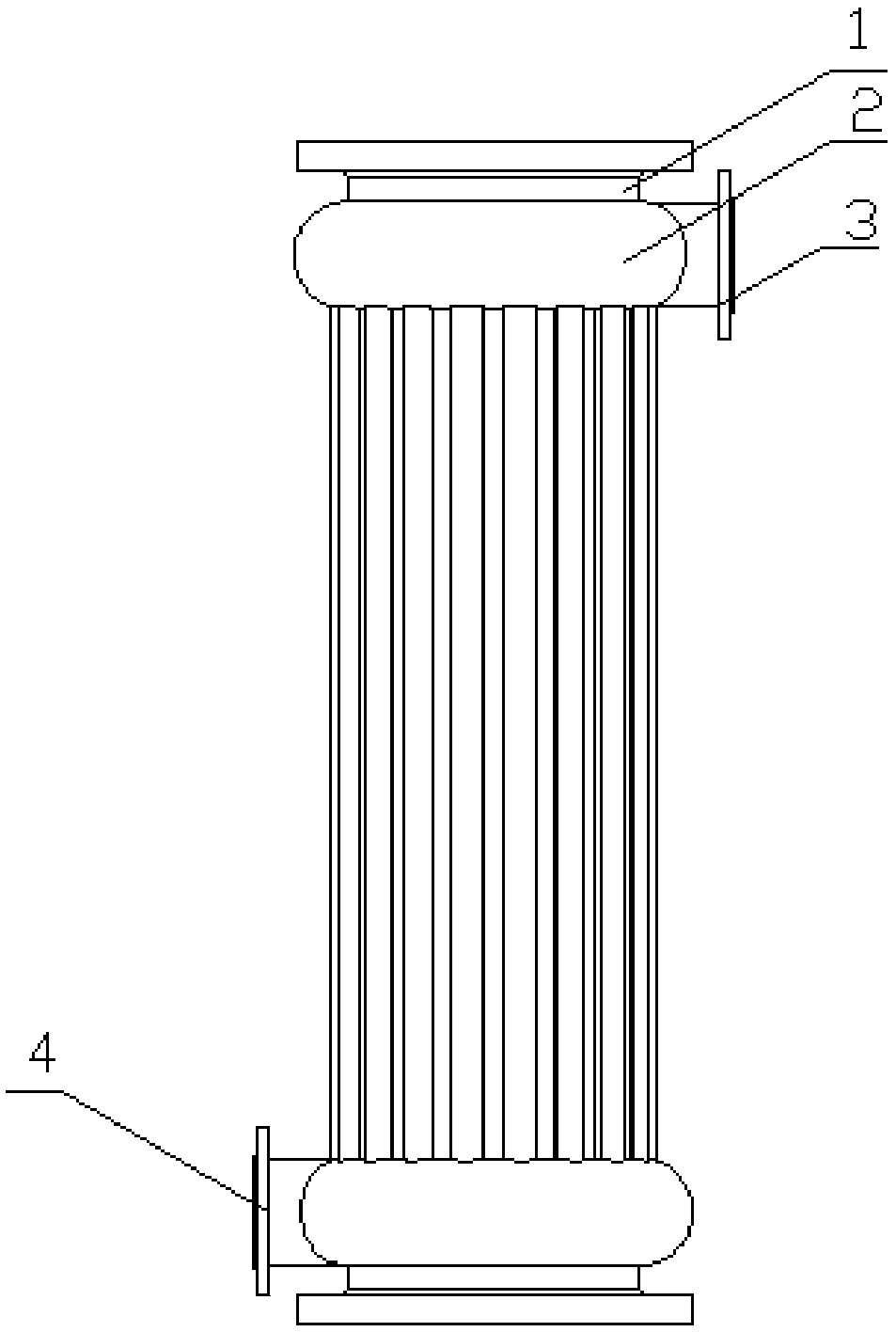

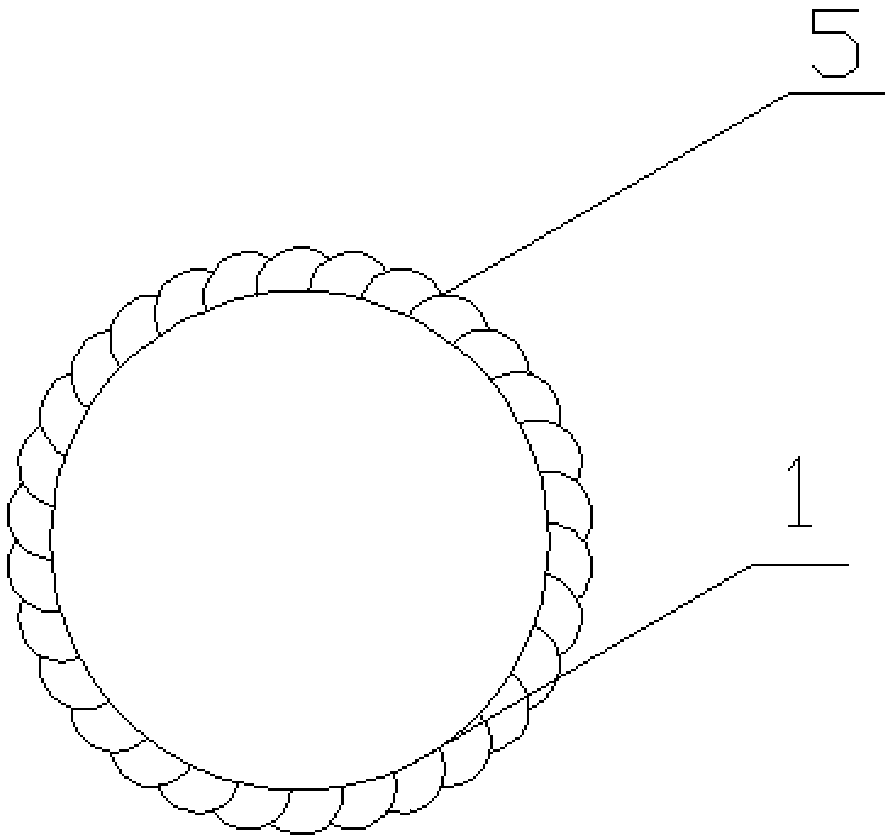

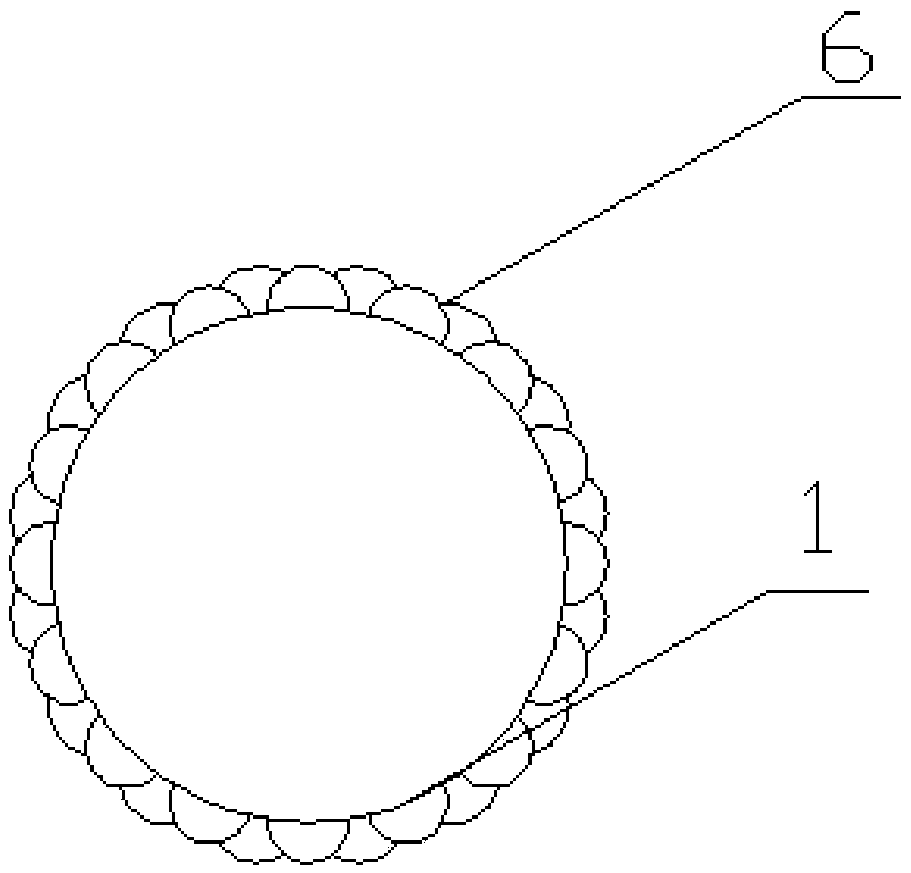

[0015] The present invention is a fish scale petal type semi-straight tube coke oven riser waste heat recovery device, such as figure 1 As shown, the fish scale flap type semi-straight tube coke oven riser waste heat recovery device is composed of a cylinder body, a semi-circular casing, a scaled semi-straight tube or overlapping semi-straight tubes, an inlet pipe and an outlet pipe from the inside to the outside. The inner wall of the cylinder is coated with a high-temperature resistant coating, which can effectively alleviate the coking phenomenon during the heat exchange process of the raw gas. The lower end of the cylinder is connected with the roof of the coke oven, from which the raw coal gas enters the riser, passes through the cylinder and enters the gas collection chamber from the upper end of the cylinder. A water inlet is set at the lower end of the semi-an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com