Coal powder entrance structure applied to reactor for producing acetylene with plasma coal cracking

A technology of plasma and reactor, applied in the direction of organic chemistry, etc., to alleviate the phenomenon, increase the yield of acetylene, and alleviate the effects of coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

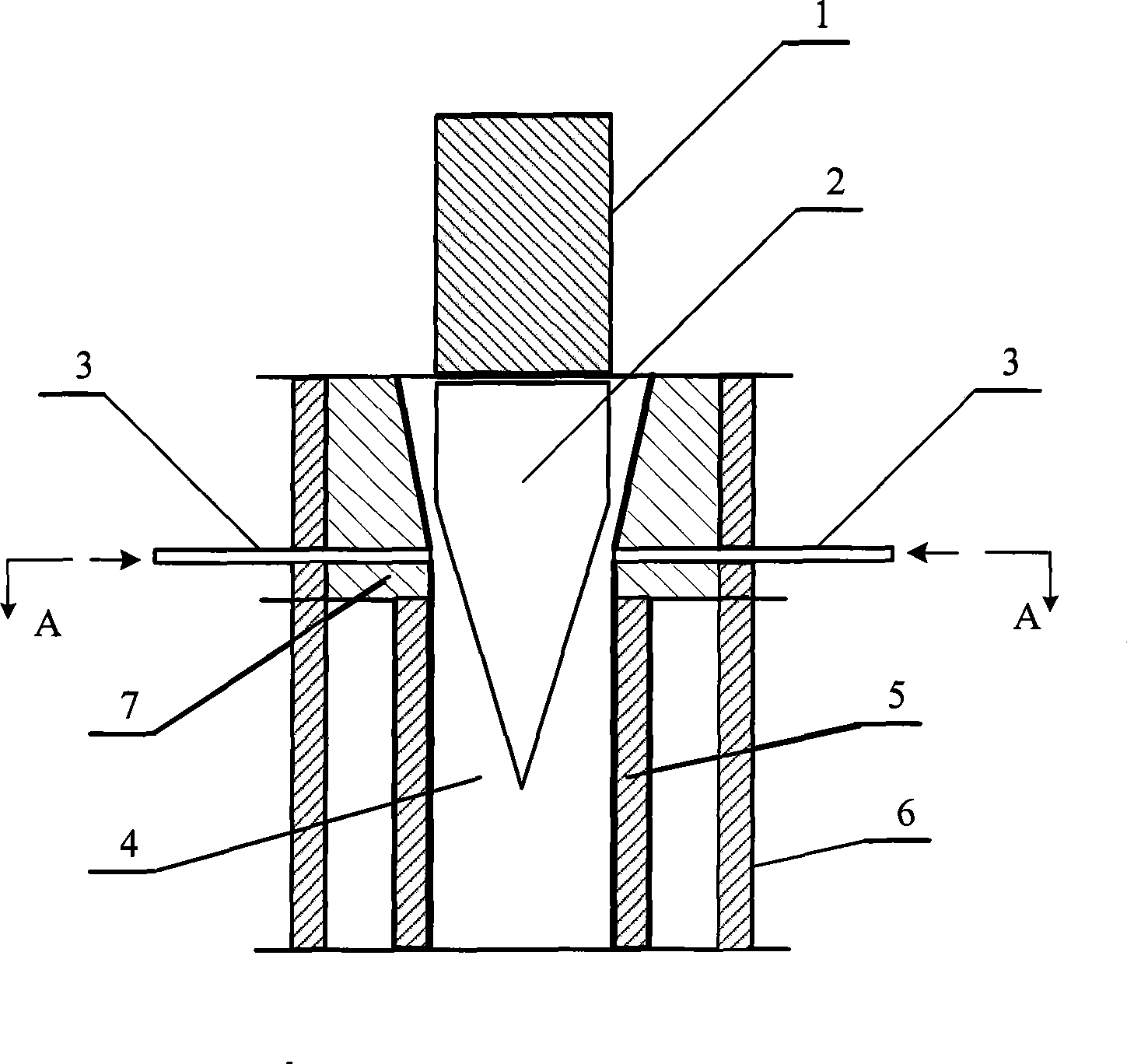

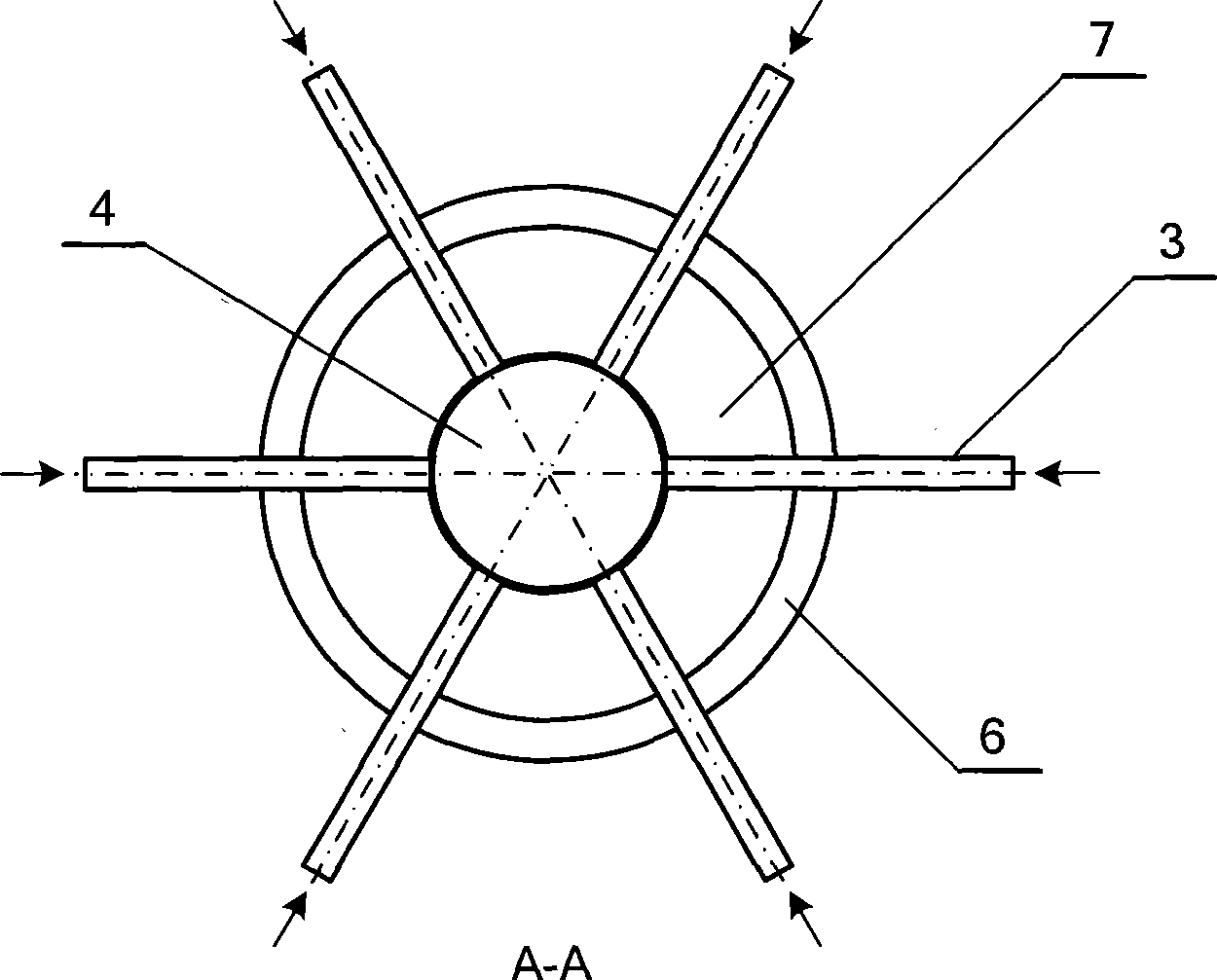

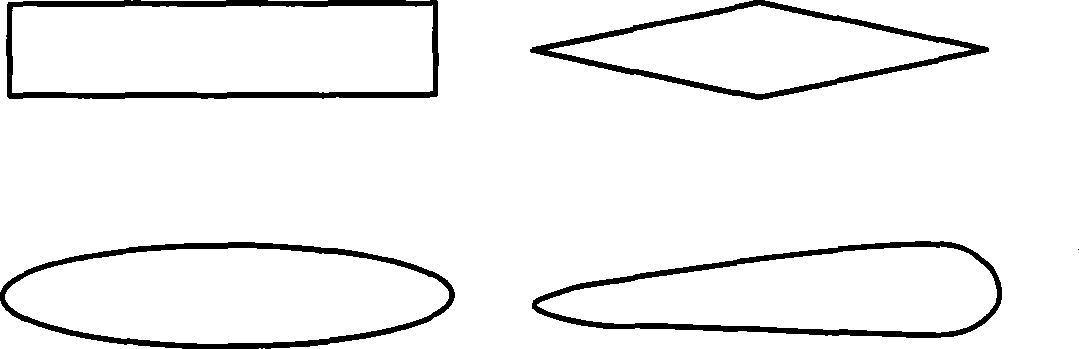

[0027] figure 1 It is a device schematic diagram of the present invention, a pulverized coal inlet structure applied to a reactor for producing acetylene by plasma coal cracking, including a plasma generator 1, a gas-solid down-bed reactor channel 4, an inner wall 7 of the reactor channel, and an outer wall 6, The graphite inner wall 5 and the pulverized coal nozzle 3 located below the plasma generator 1 and surrounding the thermal plasma jet 2 in the channel 4 of the gas-solid down-bed reactor, the pulverized coal inlet structure is as follows Figure 6 Shown in (a) and (b), the number of pulverized coal nozzles 3 is 6, and the outlet cross-section of pulverized coal nozzles 3 is wide and flat, and is a rectangle with a length of 15.6 mm and an aspect ratio of 6 ( image 3 Several typical wide and flat pulverized coal nozzle cross-sections are provided), the ratio of the 1 / 2 power of the cross-sectional perimeter P to the cross-sectional area A is 5.72, and the major axis 9 o...

Embodiment 2

[0030] A pulverized coal inlet structure applied to a reactor for producing acetylene by plasma coal cracking, comprising a plasma generator 1, a gas-solid down-bed reactor channel 4) an inner wall 7 of the reactor channel, an outer wall 6, a graphite inner wall 5 and a plasma Below the generator 1, around the pulverized coal nozzle 3 surrounding the thermal plasma jet 2 in the channel 4 of the gas-solid down-bed reactor, the pulverized coal inlet structure is as follows: Figure 6 As shown in (c) and (d), the number of pulverized coal nozzles 3 is 6, and the outlet cross-section of pulverized coal nozzles 3 is wide and flat, which is an ellipse with a major axis of 16.2mm and a ratio of major to minor axes of 6. The ratio of P to the 1 / 2 power of the cross-sectional area A is 5.82, and the major axis 9 (major axis of the ellipse) of the outlet cross-section of the pulverized coal nozzle (3) and the cross-section 8 of the reactor channel 4 have an angle α, α It is 0 °, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com