Rapid solid-state fermentation process of vinegar

A fermentation process, acetic acid fermentation technology, applied in the field of vinegar solid-state rapid fermentation process, can solve the problems of high labor intensity, long fermentation cycle, poor sanitary conditions, etc., and achieve the effects of increasing production capacity, improving the utilization of raw and auxiliary materials, and shortening the fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

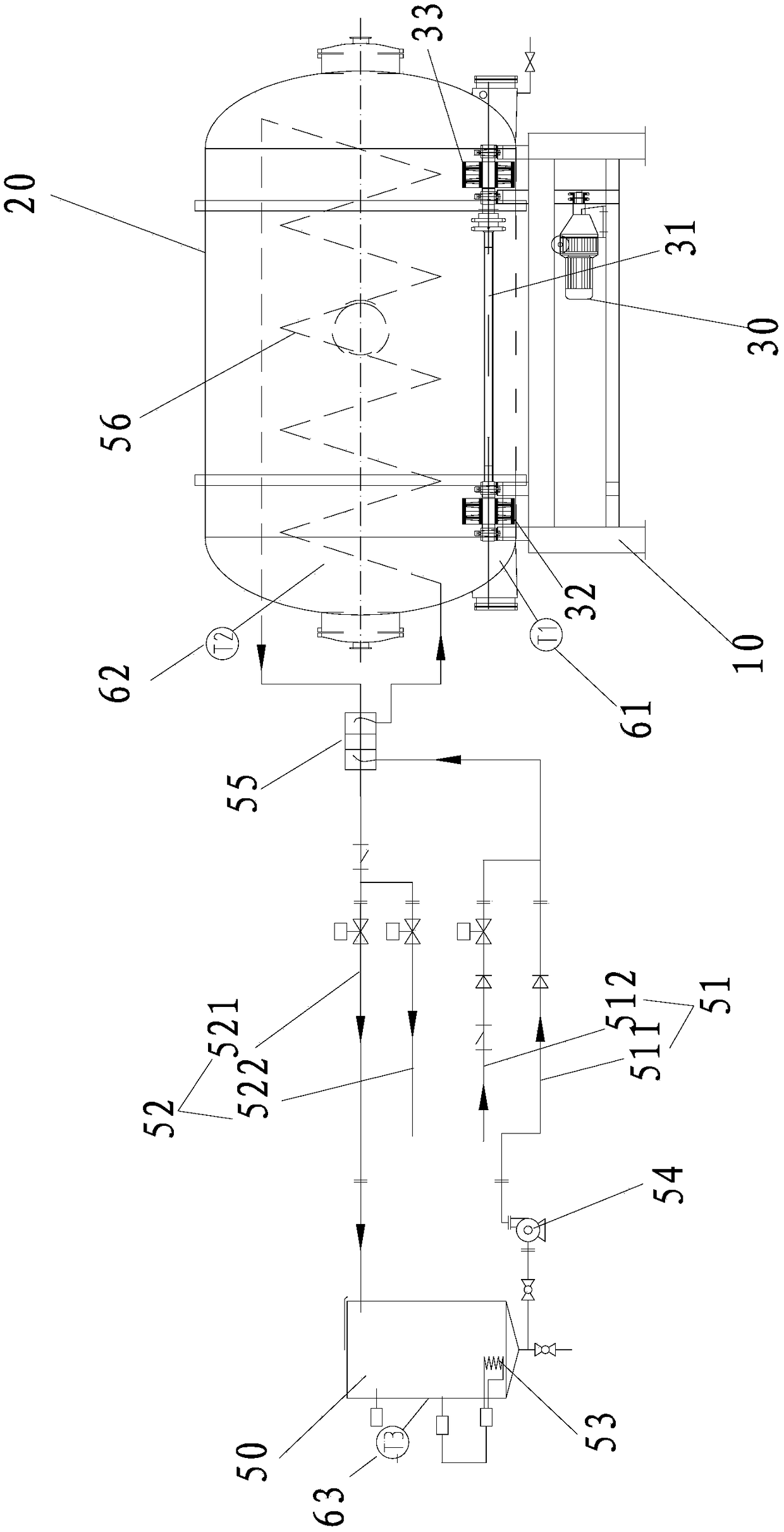

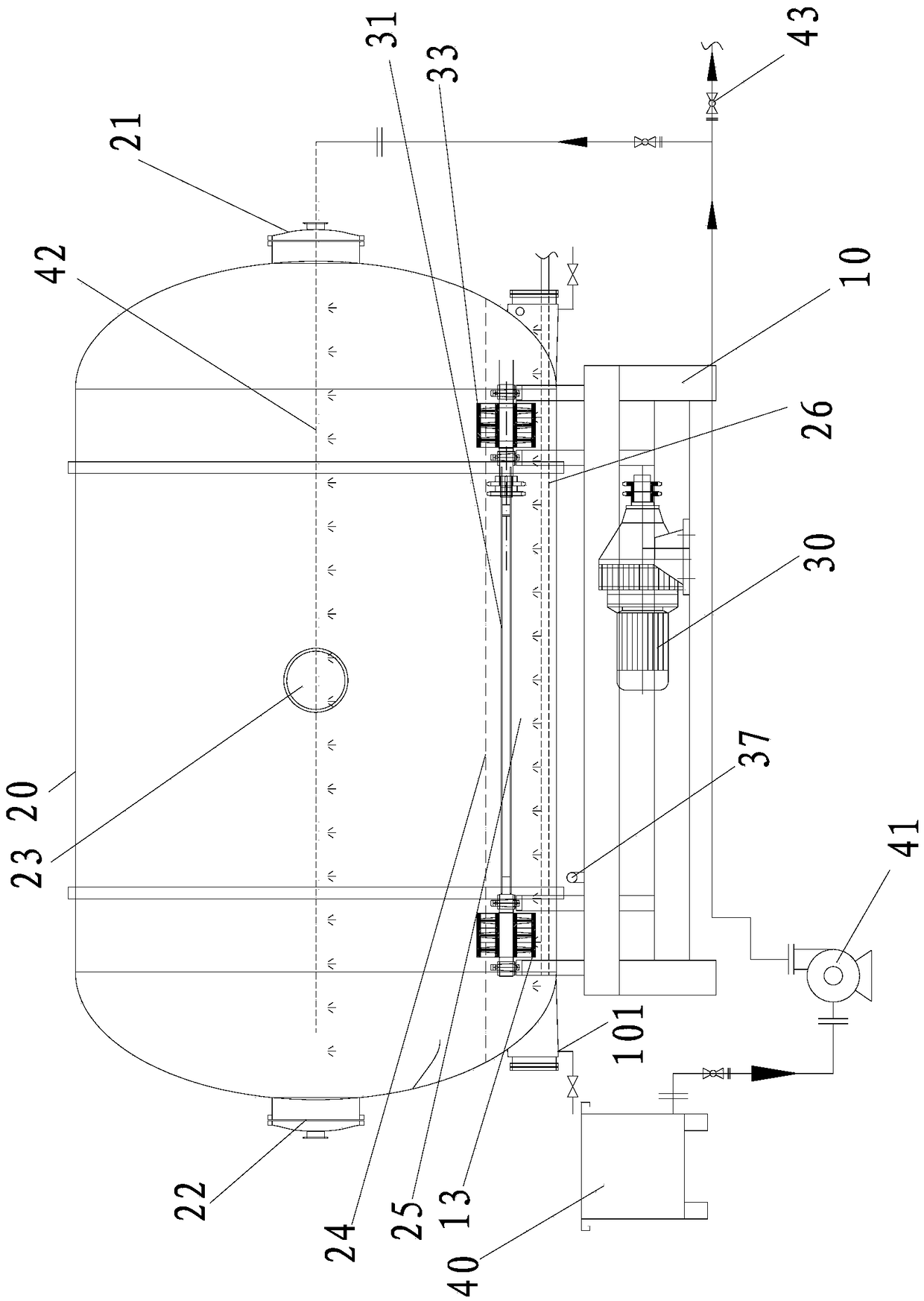

[0051] refer to Figure 1 to Figure 8 , first introduce the vinegar solid-state fermentation machine of the present invention, which comprises a frame 10 and a horizontal cylindrical tank body 20 arranged on the frame 10, the tank body 20 is provided with a feed inlet, a discharge port 21 and a liquid outlet Port 101, the feeding port can be the manhole 23, and the feeding port can also be set at other positions of the tank body 20.

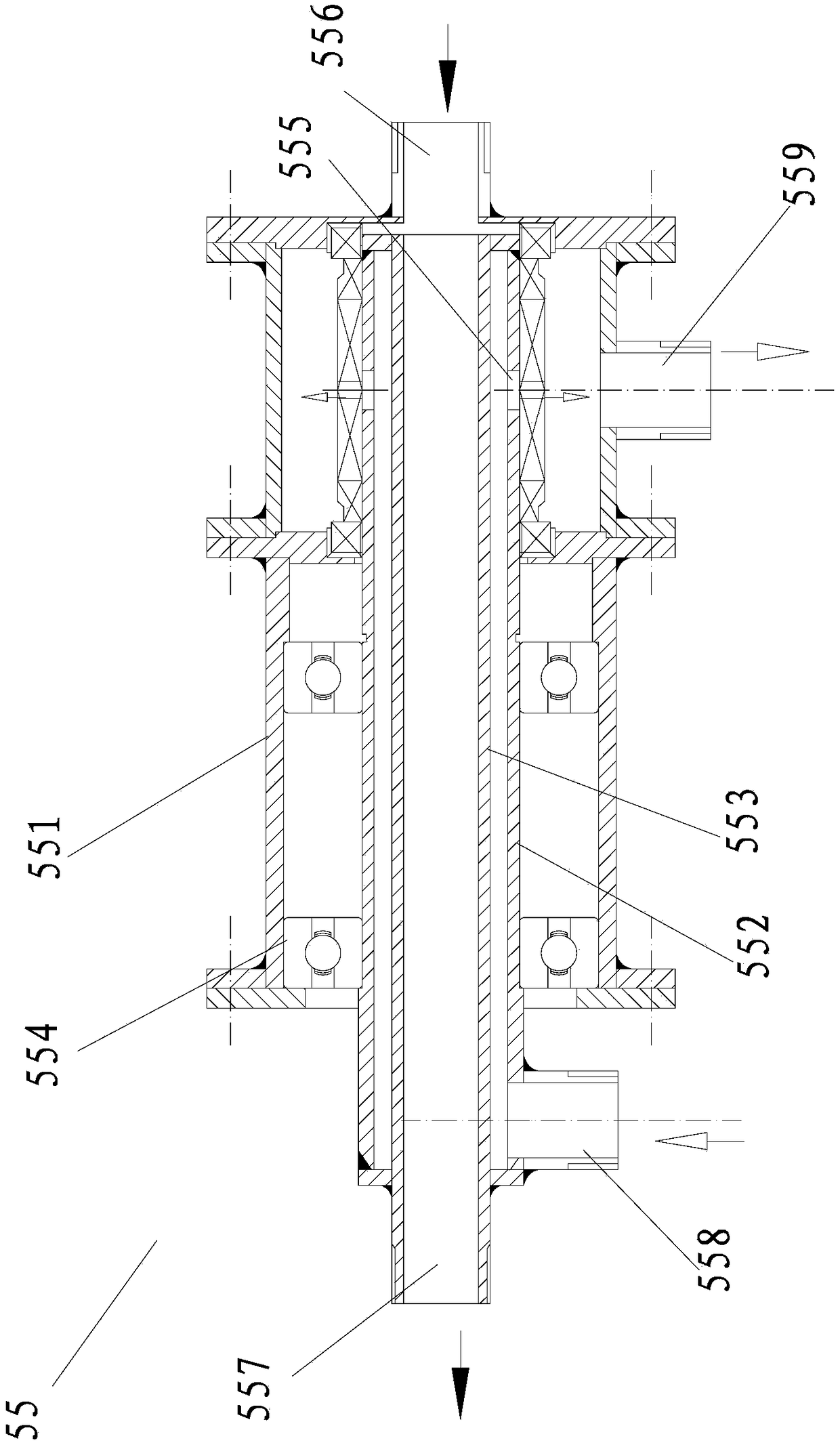

[0052]In the present invention, the tank body 20 is rotatably arranged on the frame 10, and also includes a driving mechanism for driving the tank body 20 to rotate. The tank body 20 is provided with a heat exchange tube 56, and the heat exchange tube 56 is connected to To the constant temperature control mechanism, the inner wall of the tank body 20 is provided with stirring bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com