Vertical multi-source steam waste heat recovery energy-saving device

A steam waste heat and energy-saving device technology, which is applied in the field of energy-saving devices and vertical waste heat recovery devices, can solve the problems of insufficient utilization of waste steam, difficulty in temperature matching, and affecting production efficiency, etc., achieving significant energy-saving effects, stable operation, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention is described in further detail:

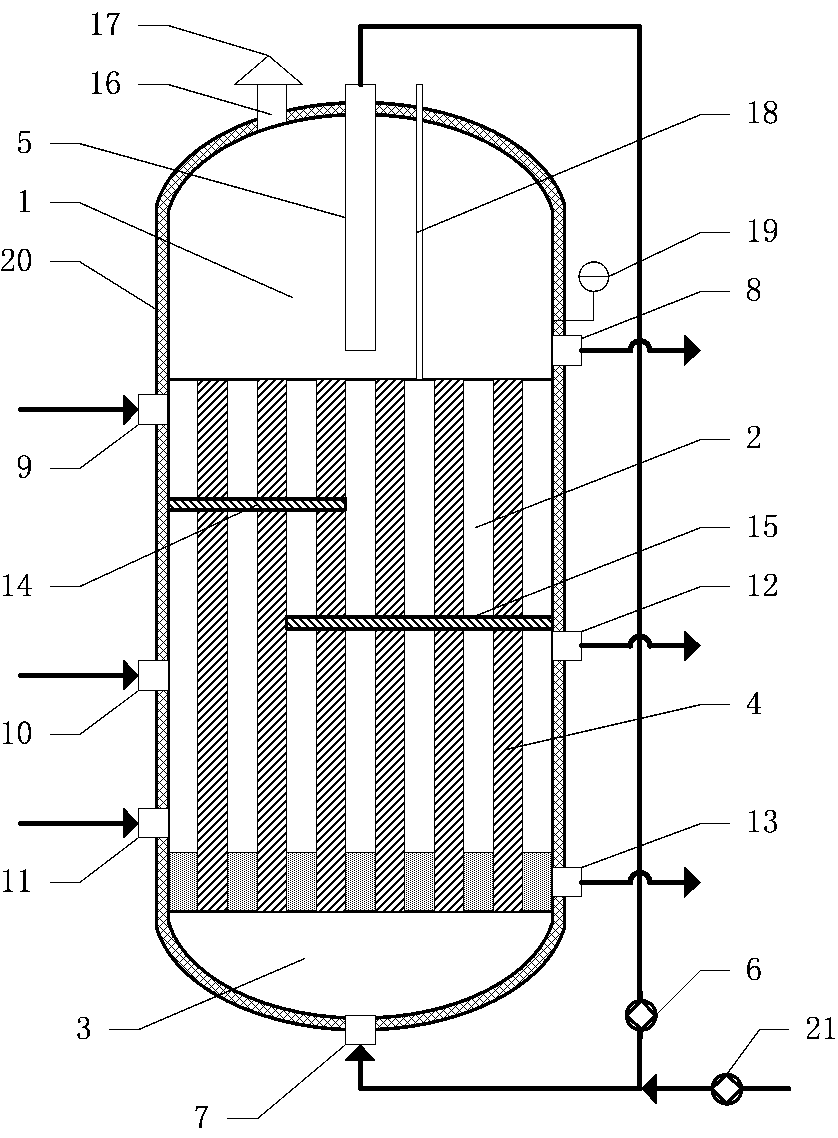

[0024] like figure 1 Shown is a schematic structural diagram of a vertical multi-source steam waste heat recovery energy-saving device. figure 1 Among them, the device includes an upper liquid storage chamber (1), a heat exchange chamber (2), a lower liquid storage chamber (3), a column tube (4), a suction pipe (5), a circulation pump (6), a liquid inlet port (7), liquid outlet (8), first steam inlet (9), second steam inlet (10), condensed water inlet (11), exhaust gas outlet (12), condensed water outlet (13), first Partition (14), second partition (15), breathing port (16), dust cover (17), liquid level gauge (18), thermometer (19), insulation layer (20), liquid rehydration pump (21) .

[0025] The liquid to be heated is generally clean water, which is replenished through the liquid inlet (7) at the bottom of the lower liquid storage chamber (3) through the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com