Bolt fastening monitoring system by using proximity sensors

A technology of proximity sensors and monitoring systems, applied in the direction of instruments, measuring devices, etc., can solve the problems of high cost and difficult implementation, and achieve the effects of low cost, high recognition, and reduced IO interfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

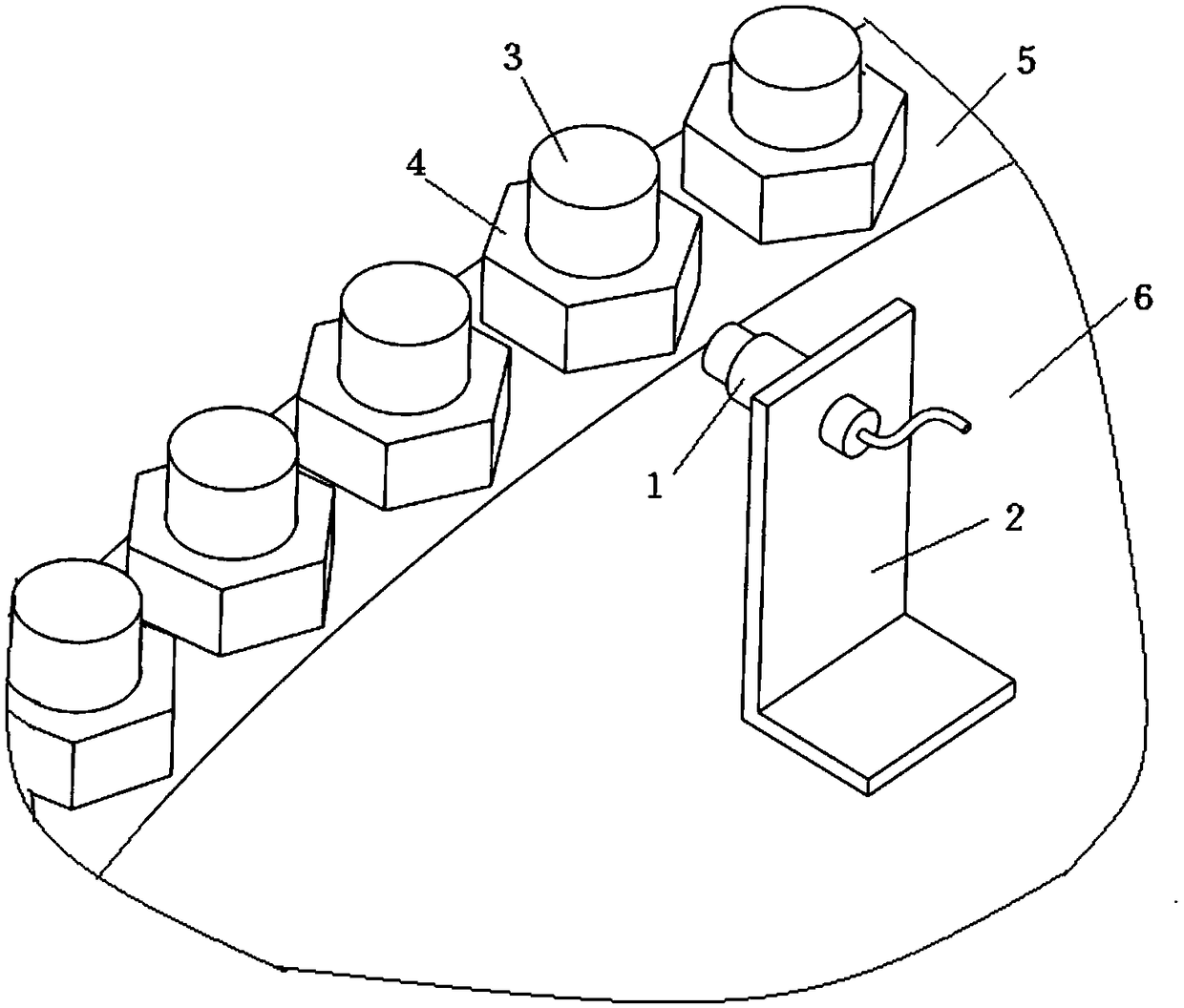

[0018] Such as figure 1 As shown, a bolt fastening monitoring system using a proximity sensor includes a proximity sensor 1, a sensor bracket 2, an alarm device, a monitoring device, and the like. Proximity sensor 1 is installed on sensor bracket 2, and is aligned with measured bolt 3 and nut 4 on rotating component 5, and proximity sensor bracket 2 is connected on relatively stationary component 6 (such as the body of the hub).

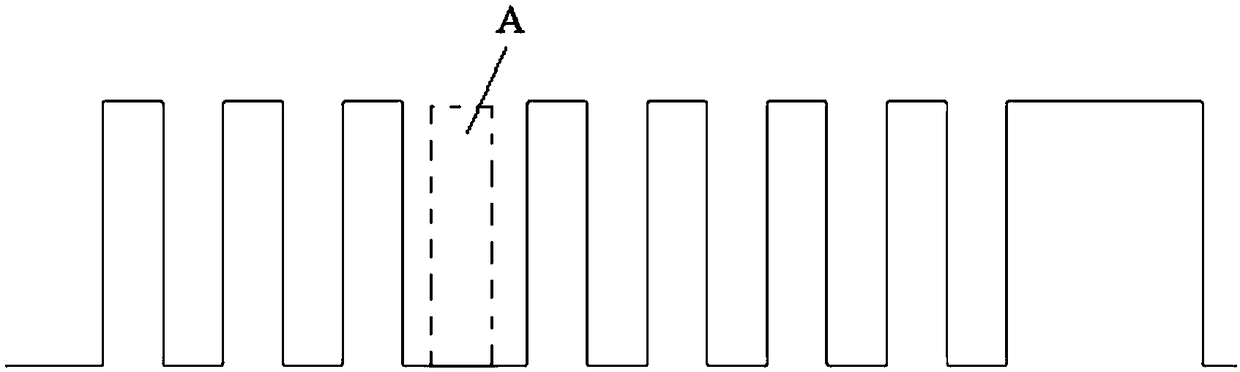

[0019] During the rotation or movement of the parts, at least one proximity sensor 1 detects each bolt 3 and nut 4 in turn. When the bolt 3 is loose, the proximity sensor 1 detects the missing pulse or level signal A, such as figure 2 shown. After identifying the missing signal, the proximity sensor 1 transmits the detected missing pulse or level signal to the alarm device, and the alarm device will give an alarm.

[0020]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com